Robot external active gravity compensation system and simulation verification method

A technology of gravity compensation and simulation verification, applied in the field of robotics, can solve the problems of reducing joint response ability, not applicable to gravity compensation of large mass loads, and unable to simulate and verify the control effect of active gravity compensation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing:

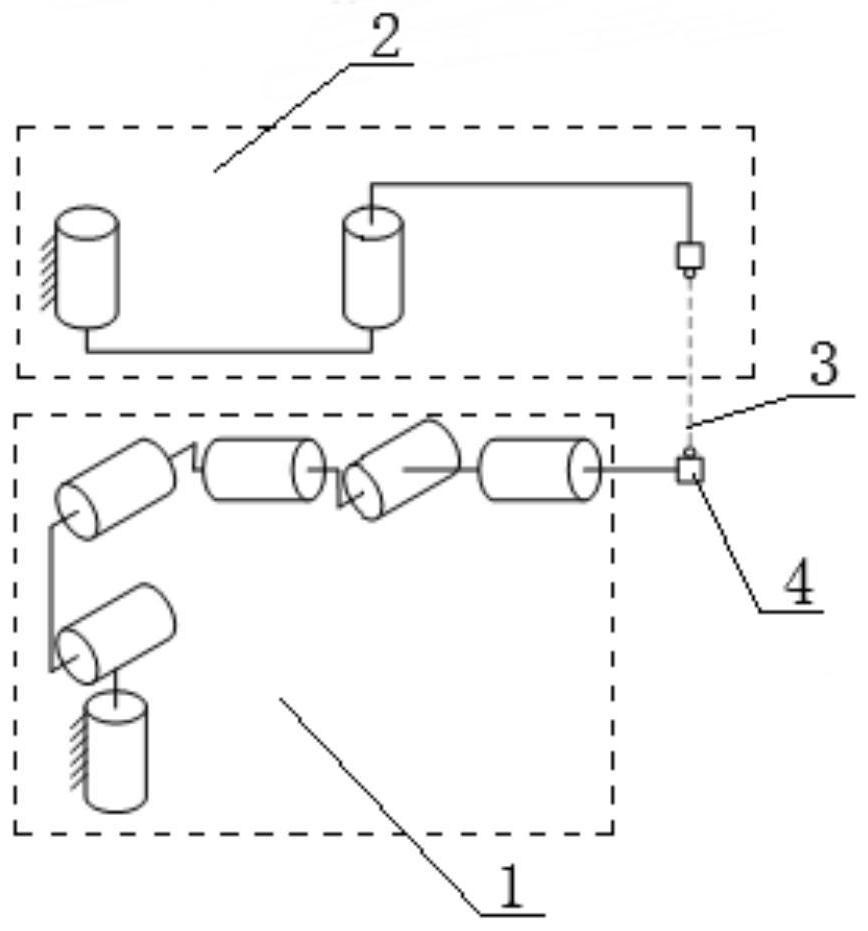

[0037] Such as figure 1 As shown: the present invention includes a gravity compensation device 2 and a gravity compensation rope 3, the force end of the gravity compensation device 2 is connected to one end of the gravity compensation rope 2, and the other end of the gravity compensation rope 2 is connected to the force end of the serial robot 1 , the force application end of the serial robot 1 is connected to the end load 4 at the same time.

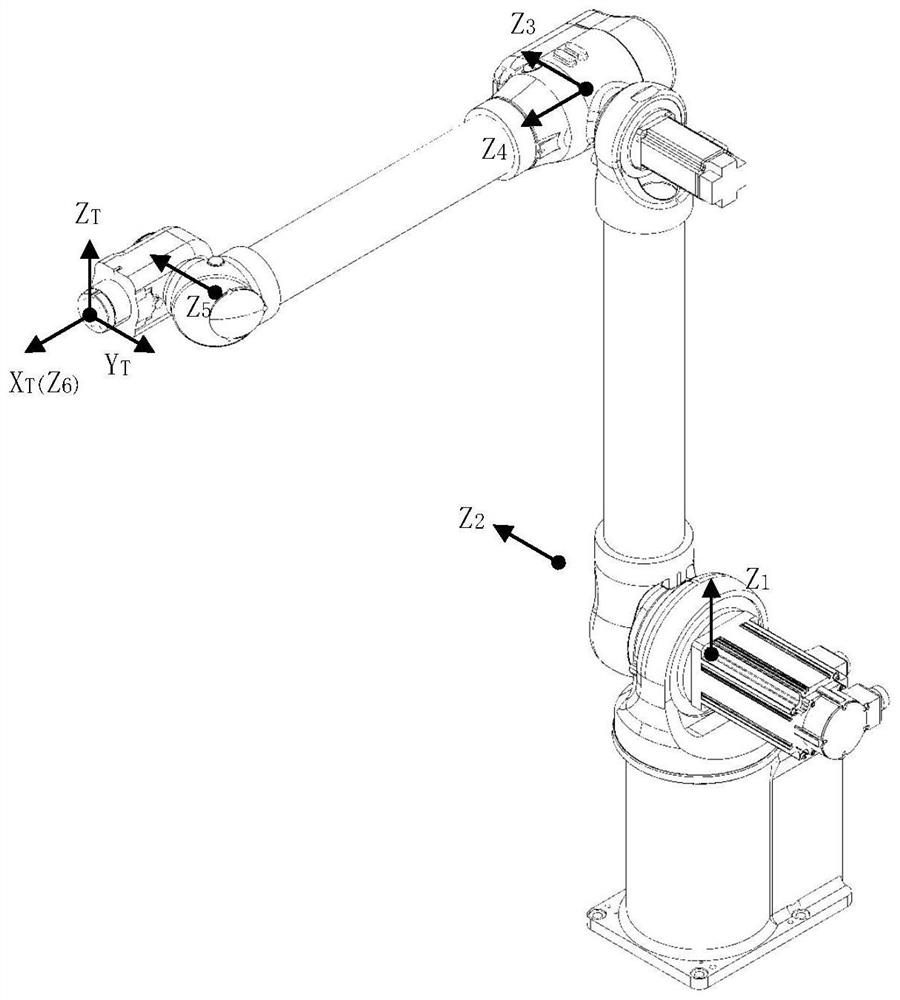

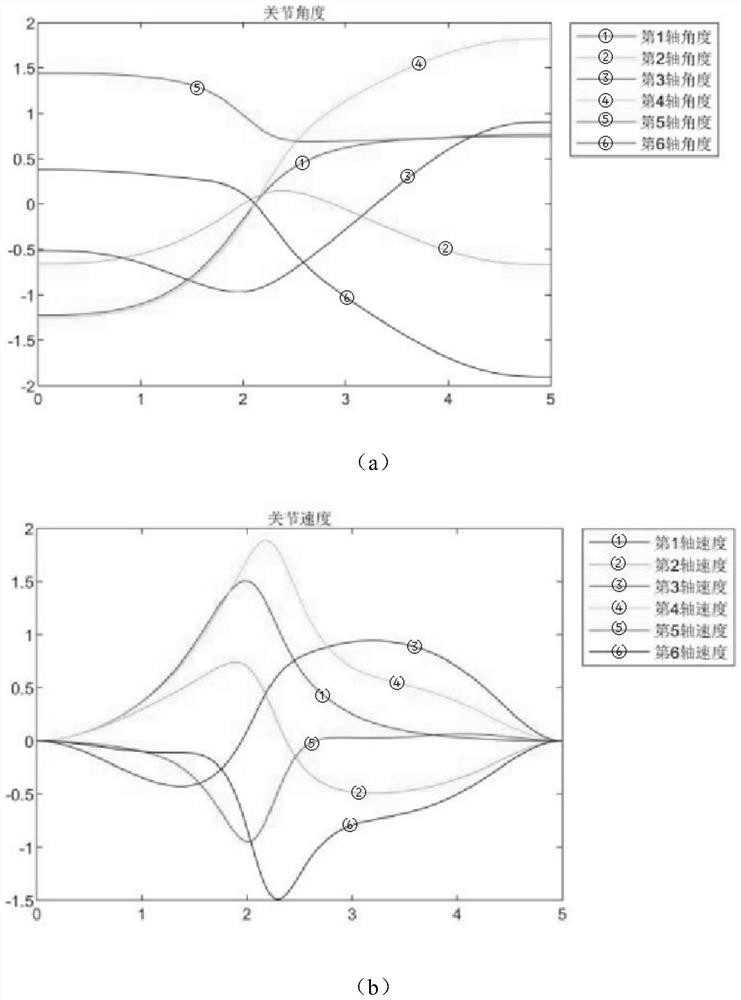

[0038] When using a small 6R robot to complete the assembly task of large-mass parts, in order to ensure the freedom of movement of the robot, an external gravity compensation system is used to directly compensate the gravity of the large-mass load at the end. The structure of robot and gravity compensation system is as follows: figure 1 shown. A variable-length belt-driven rope is used to connect the end of the robot to the end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com