Automatic transferring device

A transfer device and automatic technology, applied in the direction of lifting device, transportation and packaging, load hanging components, etc., can solve the problems of limited adaptability, loss of effective stroke, difficult to apply reasonably, etc., to achieve stable movement and small limitations , the effect of strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

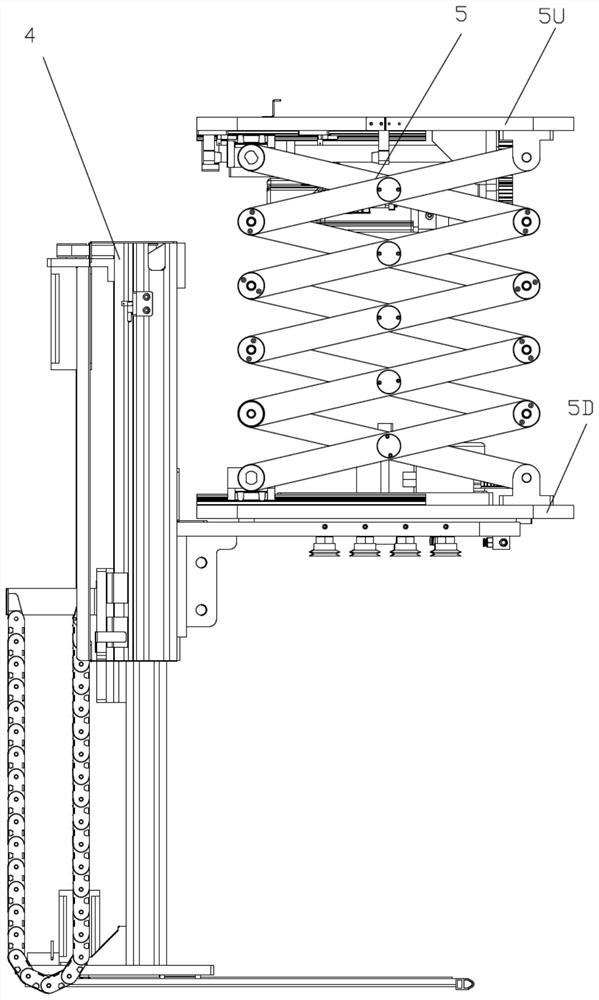

[0028] The basic structure of this automatic transfer device is as follows: figure 1 As shown, it includes a scissors mechanism 5 installed between the upper mounting plate and the lower mounting plate, and a bottom pallet elevating mechanism 4 connected with the scissors mechanism 5 through the lower mounting plate.

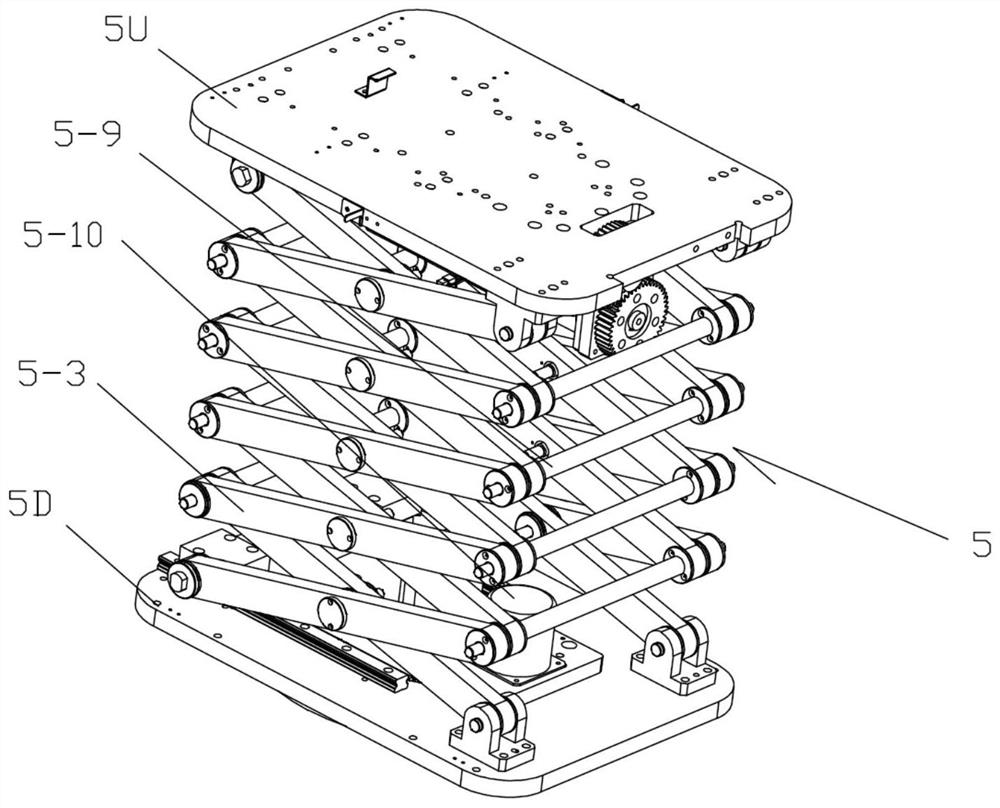

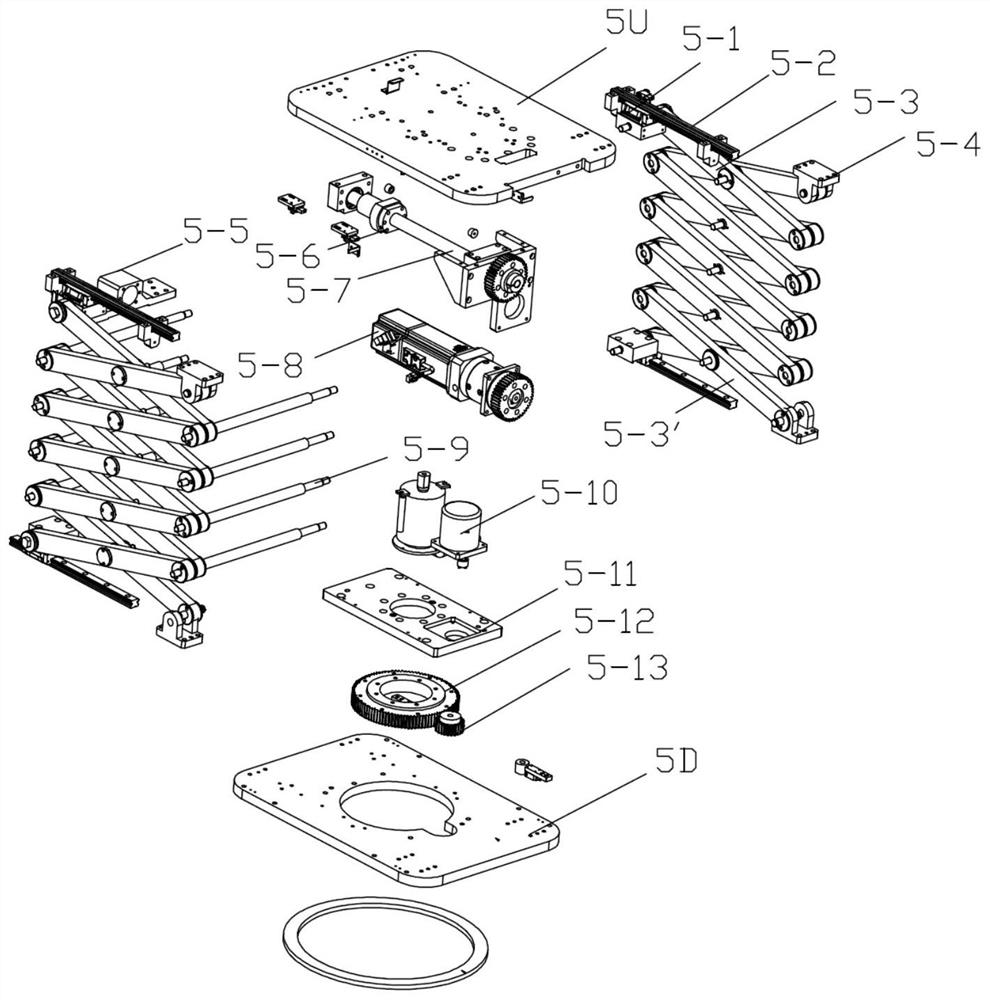

[0029] The concrete structure of scissor mechanism 5 is as figure 2 , image 3 As shown, there are left and right paired X-shaped connecting rods 5-3 each of five groups of which are hinged at the midpoint, wherein the right end of the uppermost X-shaped connecting rod is hinged on the upper hinge fixed on the lower surface of the upper mounting plate 5U. Support block 5-4, left end are hinged on upper slide block 5-1, and this upper slide block 5-1 and the upper slide rail 5-2 that is fixed on the upper mounting plate 5U lower surface constitute mobile pairs. The right end of the bottom X-shaped connecting rod 5-3' is hinged on the lower hinge support fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com