Cylindrical self-circulation denitrification integrated sewage treatment equipment based on aerobic granular sludge

A technology for aerobic granular sludge and sewage treatment equipment, which is applied in water/sludge/sewage treatment, biological water/sewage treatment, aerobic and anaerobic process treatment, etc. Problems such as dead corners of equipment and sludge accumulation can be avoided to prevent sludge from turning black and floating up, and prevent sludge from accumulating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

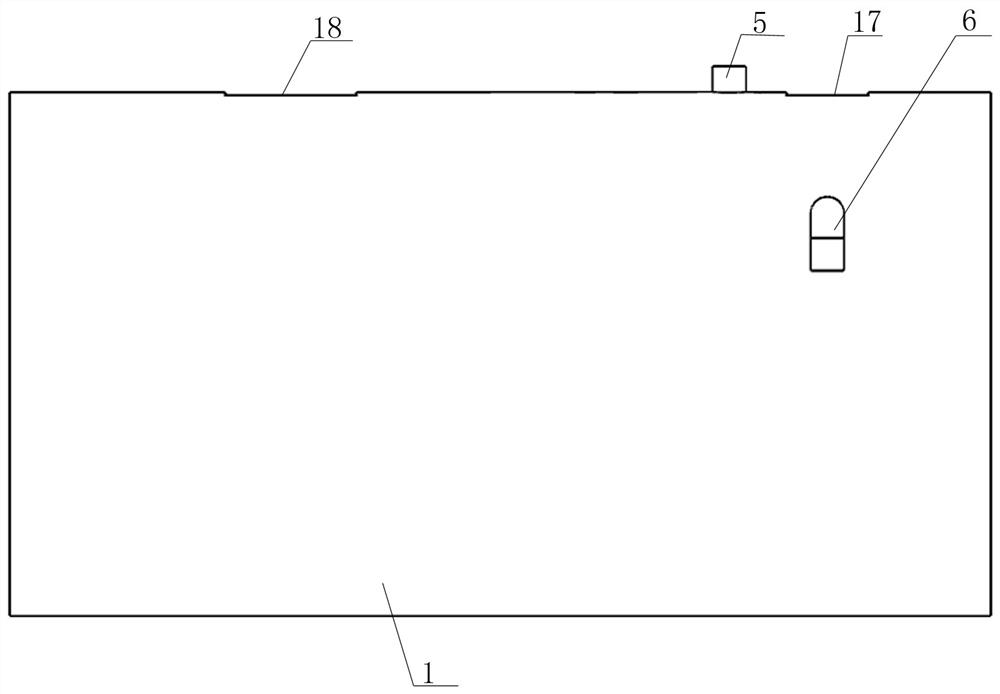

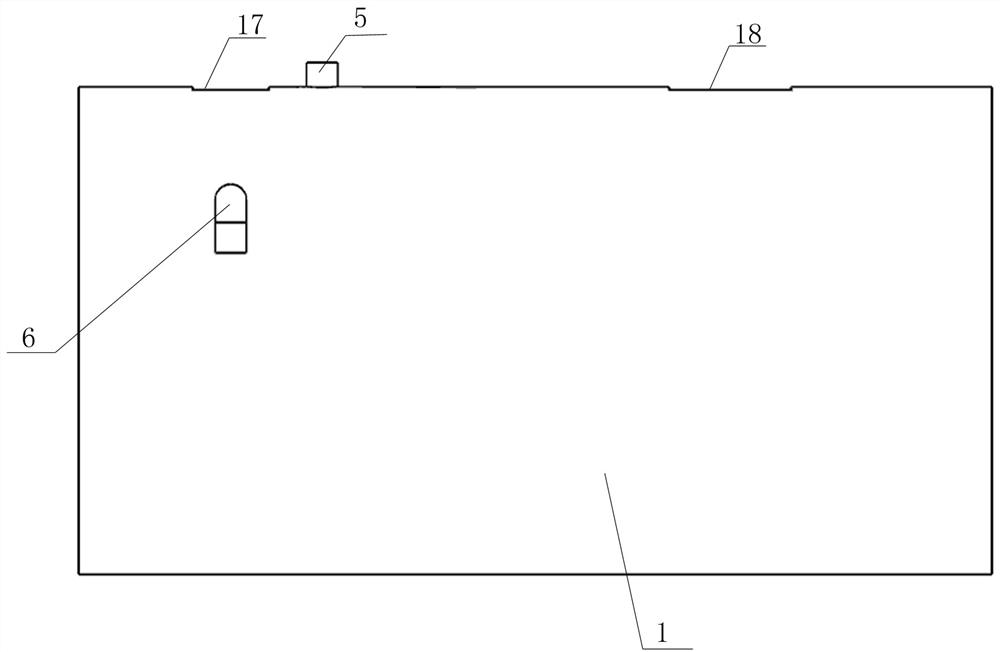

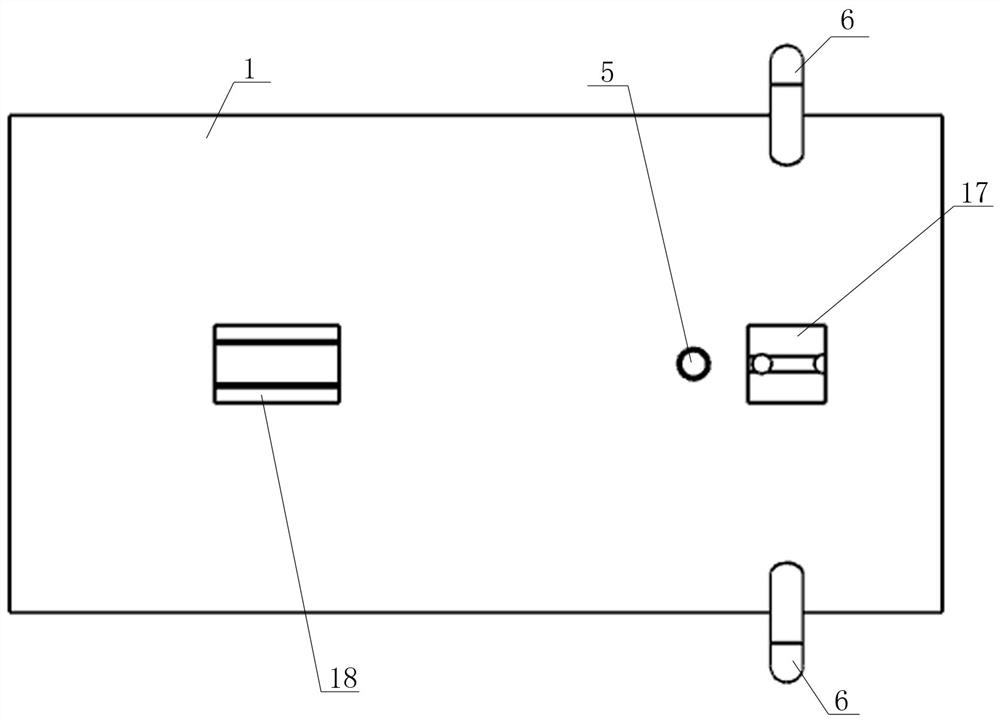

[0029] Such as Figure 1 to Figure 5 As shown, the front view, rear view, top view, perspective view and perspective view of the cylindrical self-circulating denitrification integrated sewage treatment equipment of the present invention are provided respectively, Figure 7 with Figure 8 A cross-sectional view is given, Image 6 A schematic diagram of the structure after the shell is removed is given. The integrated sewage treatment equipment shown is composed of a cylinder body 1, a partition plate 2, an aeration tank 3, an upflow reaction tank 4, an inlet pipe 5, an outlet pipe 6, and an aeration tank. Air unit 7, return pipe 8, water distribution pipe 9, water outlet weir 10, water collection tank 11, aeration tank inlet pipe 12, upper baffle 14 and lower baffle 15, the cylinder 1 is placed horizontally and horizontally, and its interior is a cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com