Novel track full-assembly type integrated industrial system

A fully assembled, track-based technology, applied in the field of rail transit, can solve problems such as complex construction procedures, high cost of measures, and large hoisting tonnage of prefabricated components, and achieve the effects of simple and convenient connection methods, improved spanning capacity, and lightened structural weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0041] It should be understood that the terms "first", "second", etc. are used in the present invention to describe various information, but these information should not be limited to these terms, and these terms are only used to distinguish information of the same type from each other. For example, without departing from the scope of the present invention. "First" information may also be referred to as "second" information, and "second" information may also be referred to as "first" information.

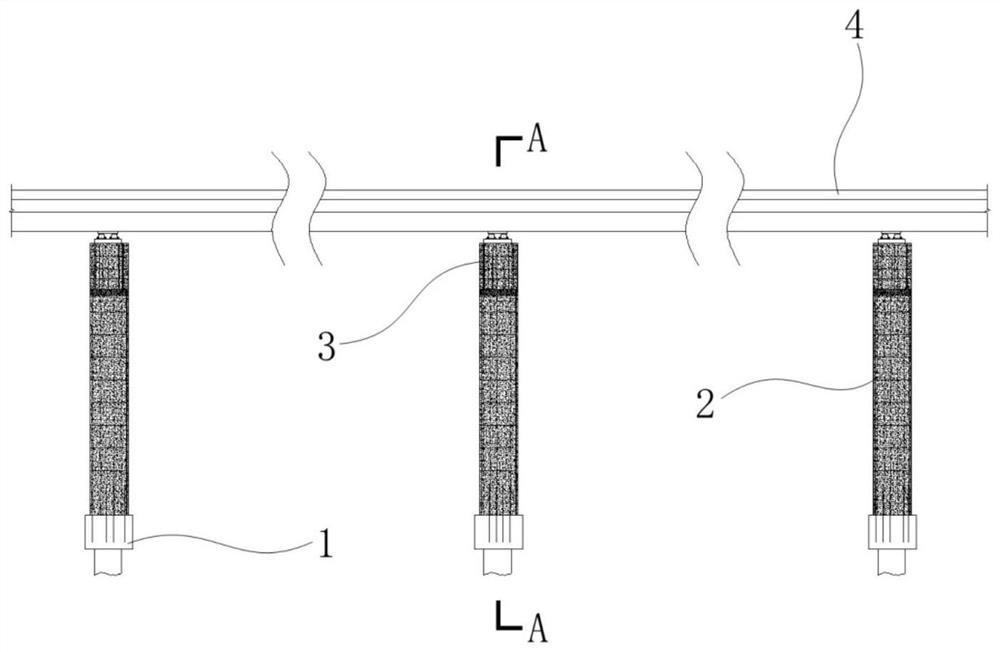

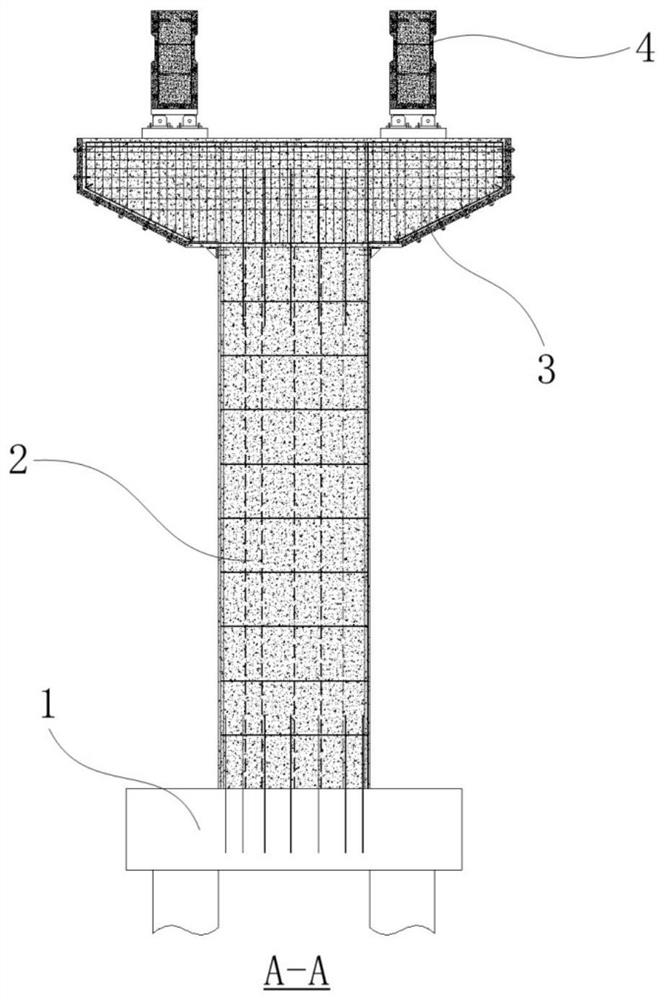

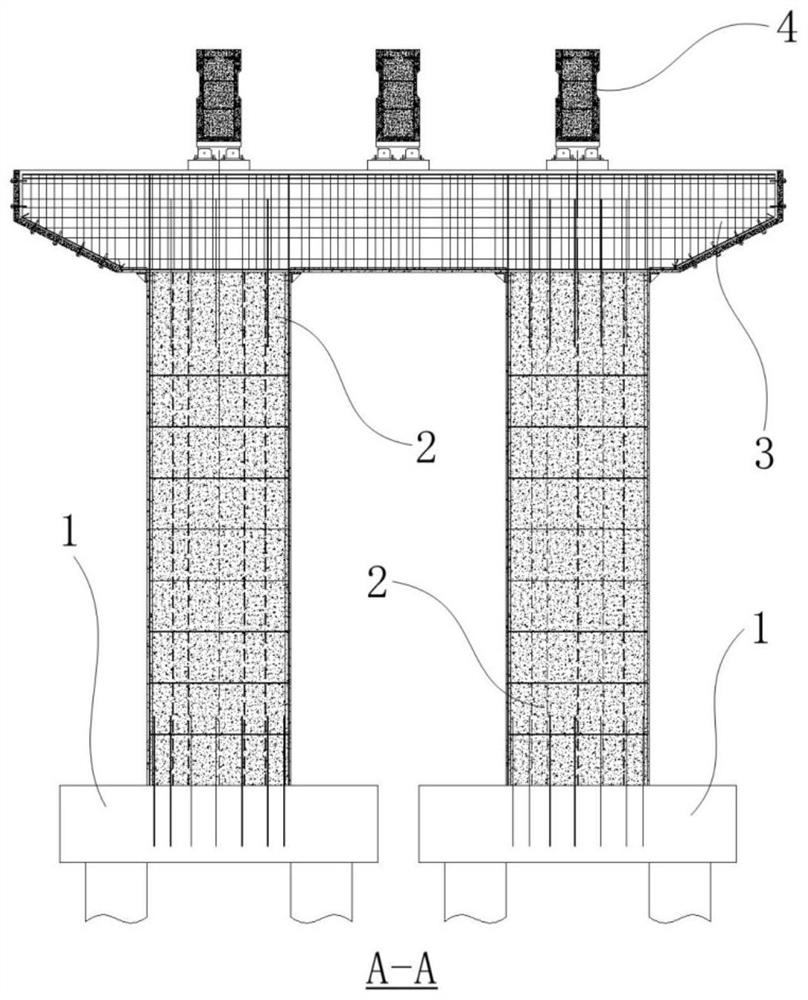

[0042] Such as Figure 1 to Figure 17 As shown, the embodiment of the present invention provides a new type of track fully assembled integrated industrialization system, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap