Municipal soft foundation road reinforcing method

A soft foundation and road technology, applied in roads, roads, infrastructure engineering and other directions, can solve the problems affecting the forming quality of the supporting disk pile, the supporting disk cavity cannot be extruded and expanded, and it is easy to collapse and collapse, so as to shorten the construction period. , the effect of improving quality and improving overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

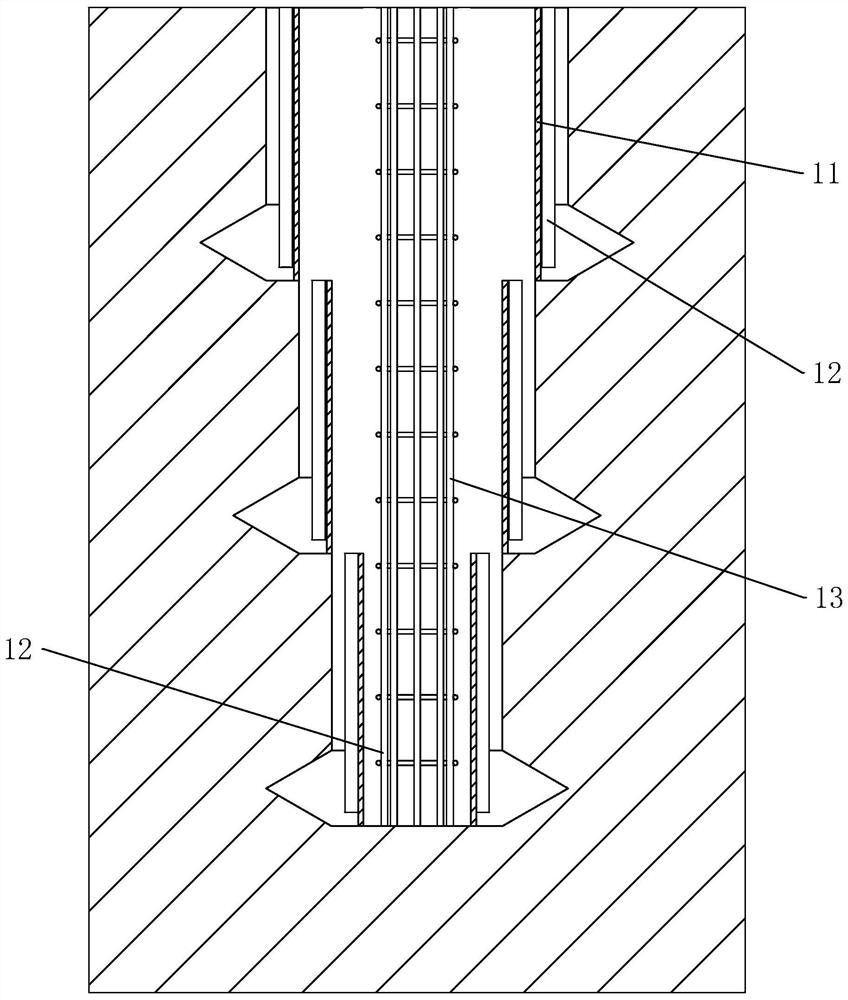

[0040] The application will be described in further detail below in conjunction with the accompanying drawings.

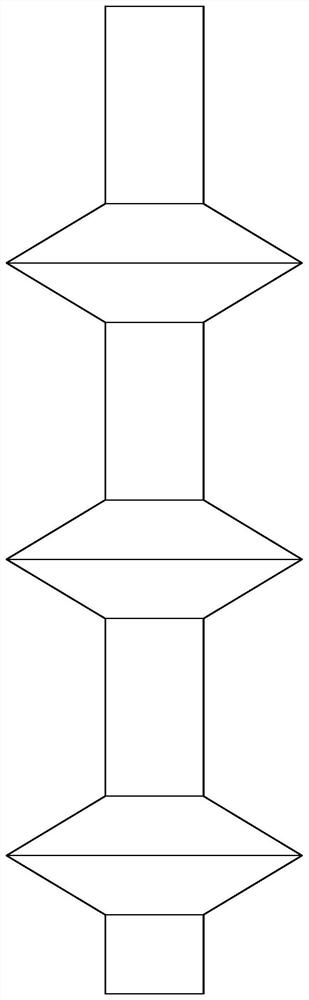

[0041] First, refer to the attached figure 1 , a brief introduction to the extruded and expanded branch plate grouting pile and its construction technology in the related technology. During construction, drill down to a certain depth at the designated pile position on the bottom surface, then lower the extrusion machine into the pile hole, and carry out extrusion construction at intervals from bottom to top along the axial direction of the pile hole. Squeeze up and expand to form spaced support plate cavities, and finally pour concrete grout into the pile holes. The pressure in the horizontal direction improves the anti-settling and anti-deformation capabilities of the soil. Since the hole is formed at one time, the depth of the hole is too large, and it is affected by the soil quality at different depths. During the extrusion and expansion process, the hole wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com