Equipment for improving loading efficiency of trailing suction hopper dredger

A technology for trailing suction dredgers and efficiency, which is applied in the field of equipment to improve the loading efficiency of trailing suction dredgers. The effect of sand loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

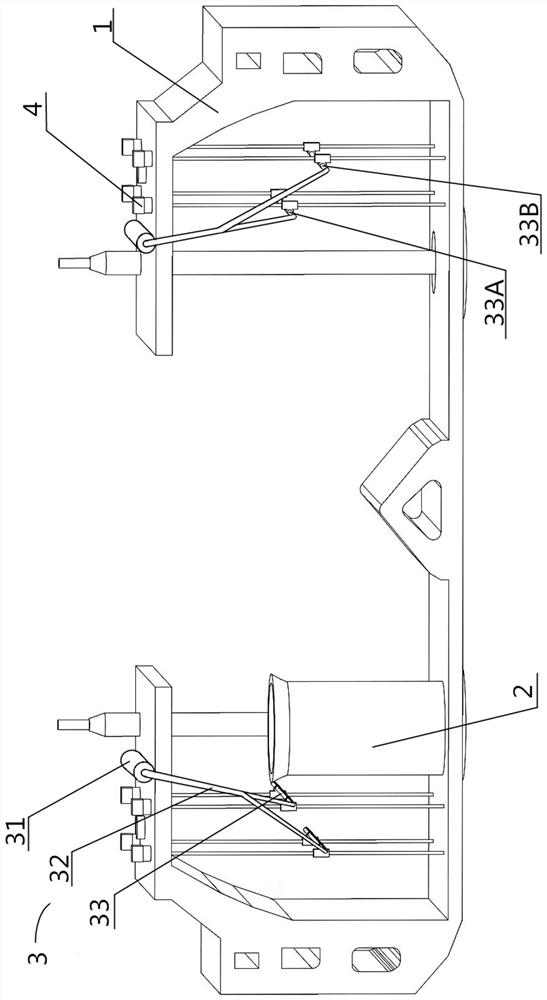

[0020] See Figure 1 to Figure 3 , the equipment used to improve the loading efficiency of the trailing suction dredger is installed in the cabin 1 of the dredger, and the overflow tube 2 is arranged in the cabin 1, and the dredger combines the sediment and water at the bottom of the river or the seabed Inhaled in the cabin 1, the silt remains in the cabin 1, while river water or seawater flows out from the overflow tube 2. The function of this device is to retain the sediment in the cabin 1 during this process, so as to avoid or reduce the flow of the sediment from the overflow tube 2 along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com