A kind of shock absorber spring pad and its processing technology

A shock absorber and spring pad technology, applied in the direction of shock absorber-spring combination, shock absorber, spring/shock absorber, etc., can solve the problems of low structural strength of the lower spring pad, increased replacement frequency, damage, etc. It is easy to deform under force, improve the service cycle, and prolong the service cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

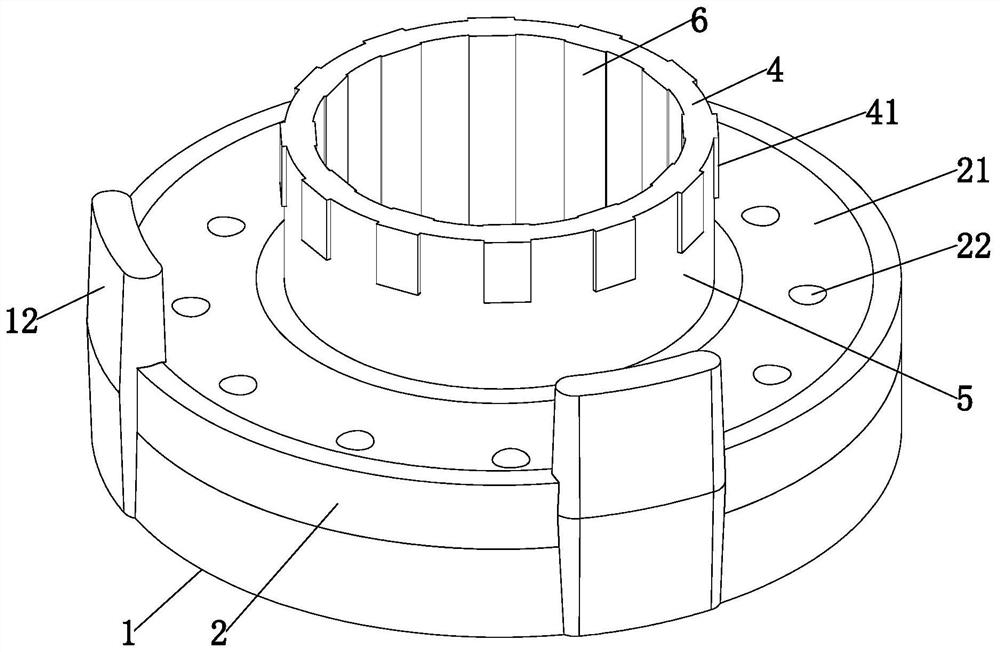

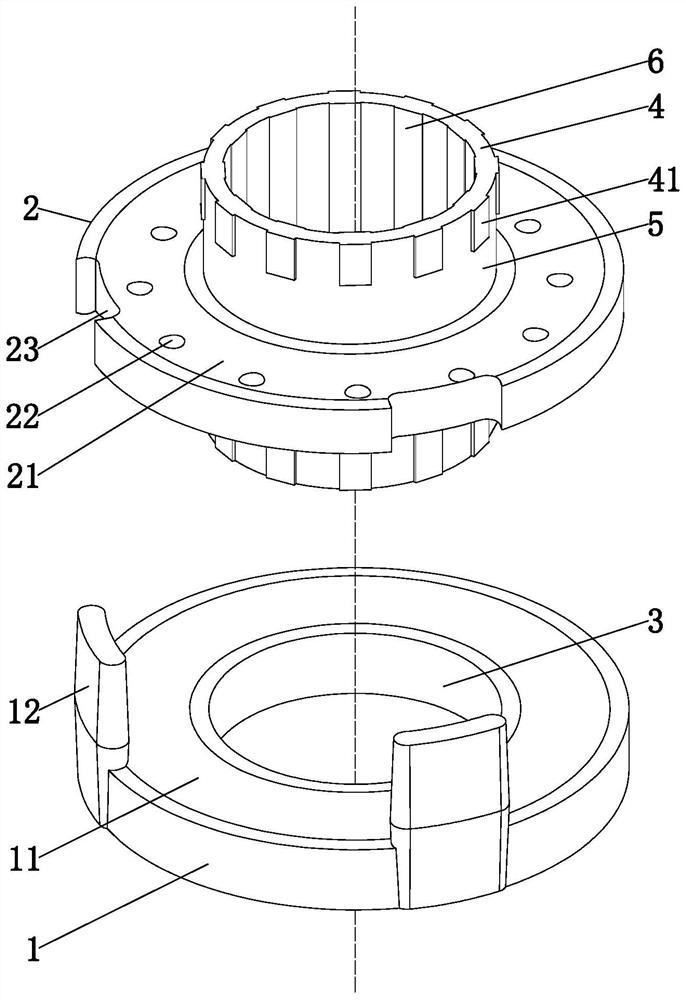

[0043] refer to figure 1 and figure 2 , a shock absorber spring pad, including a support body 1 and a limiting body 2 two-part structure, the axial direction of the support body 1 and the limiting body 2 are the same, fit and fixed together, and the two parts of the structure can be detachably connected, one part If the structure is damaged, another part of the structure can still play a supporting and buffering role, and after one part is damaged, it can be replaced, and the other part can still be used continuously.

[0044] Specifically, the support body 1 is set as a ring-shaped elastic body made of rubber. In this embodiment, natural rubber is used as the processing material. A circular through hole 3 is provided in the middle of the support body 1, and the damping rod of the shock absorber passes through the through hole 3. However, the support body 1 moves on the damper rod with the end of the damper spring. One annular side surface of the limiting body 1 is provided...

Embodiment 2

[0053] The embodiment of the present application also discloses a process for processing a shock absorber spring pad, which includes the following steps:

[0054] Step 1: According to the shape of the support body 1 and the stopper body 2, and the shape of the assembly of the fixing portion, a hot pressing die for the support body 1 and the stopper body 2 is made;

[0055] Step 2: Using natural rubber as the raw material, the support body 1 and the limiting body 2 are formed by hot pressing with a hot press molding machine respectively, so as to ensure that the limiting body 2 is integrally formed with a connecting sleeve 4, and the structural standard of the connecting sleeve 4 is the radial thickness Less than the radial thickness of the support body 1, the hardness of the connecting sleeve 4 is also less than the hardness of the support body 1;

[0056] Step 3: Assemble the supporting body 1 and the limiting body 2, cut the side wall of the connecting sleeve 4 along the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com