Micro valve used for micro channel flowing control and control method thereof

A kind of technology of flow control, control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

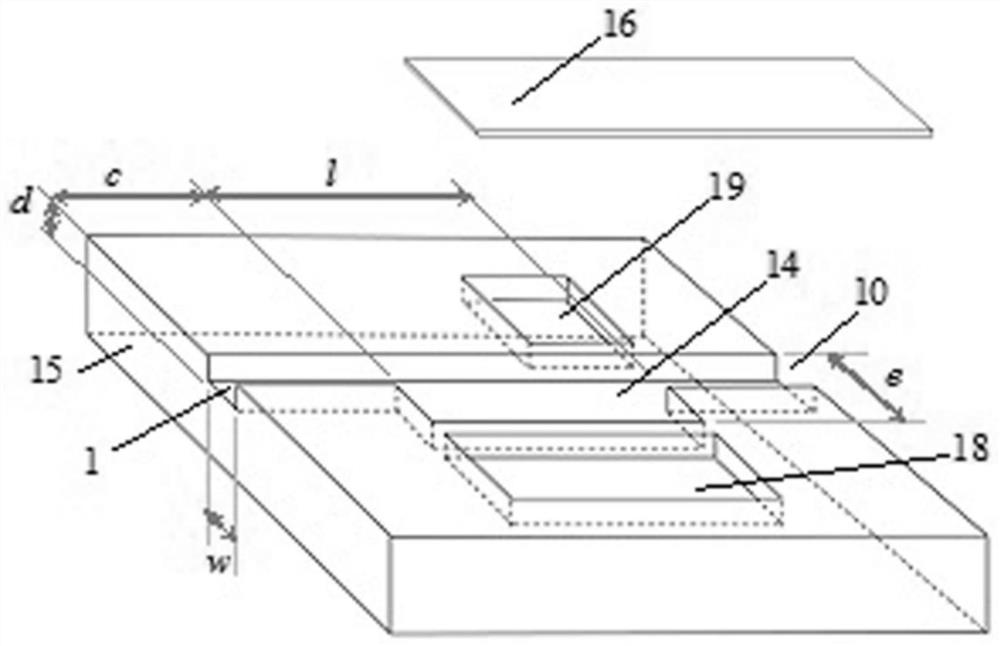

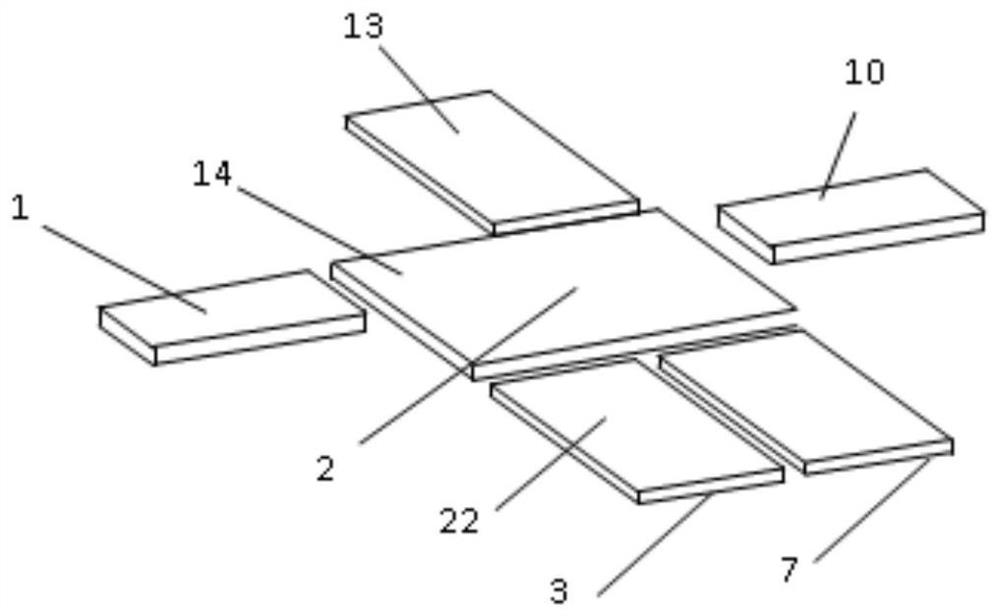

[0030] combine Figure 1, a micro-valve for micro-channel flow control, comprising a substrate 15, a micro-channel 14 is arranged in the middle of the substrate 15, an upstream micro-channel 1 is provided at one end of the micro-channel 14, a downstream micro-channel 10 is provided at the other end, and a downstream micro-channel 10 is provided at the other end of the micro-channel 14. Channel 1, microchannel 14 and downstream microchannel 10 form a series connection.

[0031] The width of the upstream microchannel 1 is equal to the width of the downstream microchannel 10, and is w, the depth of the upstream microchannel 1 is equal to the depth of the downstream microchannel 10, and is d, and the width of the microchannel 14 is that of the upstream microchannel 1 Twice the width, the width e is taken as 2w, the depth is equal to the depth of the downstream microchannel 10, which is d, and the length is l.

[0032] The inner surface of the micro-channel 14 is coated with a lef...

Embodiment 2

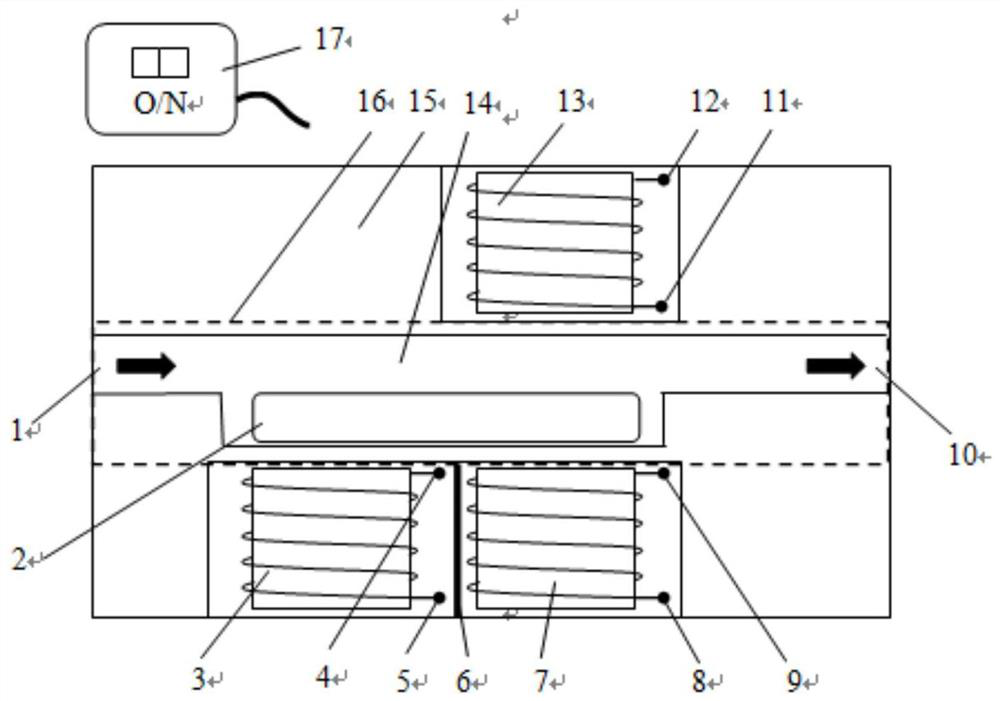

[0042] combine Figure 2-Figure 5 , a kind of control method for the microvalve of microchannel flow control, it is characterized in that, controller 17 controls the unlatching of first miniature magnetic field generator 3, the second miniature magnetic field generator 7 and the 3rd miniature magnetic field generator 13, Form vertical or horizontal magnetic field lines; change the pressure difference between the upstream microchannel 1 and the downstream microchannel 10 to change the magnetic intensity.

[0043] When the valve is opened, the first miniature magnetic field generator 3 and the second miniature magnetic field generator 7 are opened by the controller 17, and the third miniature magnetic field generator 13 is closed, so that the magnetorheological fluid 2 is attracted by the lines of magnetic force and fixed on the miniature magnetic field generator. The channel 14 is close to the side of the slot 18 where the first micro-magnetic field generator is placed, and the...

Embodiment 3

[0048] The control methods of the three miniature magnetic field generators on the magnetorheological fluid 2 include:

[0049] 1. When the valve is opened, the magnetorheological fluid 2 is piled up on the side of the micro-channel 14 close to the first micro-magnetic field generator placement groove 18, and the fluid medium flowing through the upstream microchannel 1 and the downstream microchannel 10 has a positive impact on the magnetorheological fluid. 2 acts on the friction force along the flow direction. At this time, the resultant force of the magnetic field force of the first micro-magnetic field generator 3 and the second micro-magnetic field generator 7 acting on the magnetorheological fluid 2 and the surface tension of the micro-channel 14 and the fluid and the frictional force between the magnetorheological fluid 2 is balanced, and the magnetorheological fluid 2 is in a static and stable state;

[0050] 2. When the valve is closed, the magnetorheological fluid 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com