Method for monitoring dispersion uniformity of lithium ion battery slurry on line

A lithium-ion battery, uniformly dispersed technology, applied in the preparation of secondary batteries, battery electrodes, test samples, etc., can solve the problems of unguaranteed safety performance, poor reliability of evaluation data, and long evaluation period, etc. Achieve the effect of saving production time, shortening evaluation cycle, and enhancing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

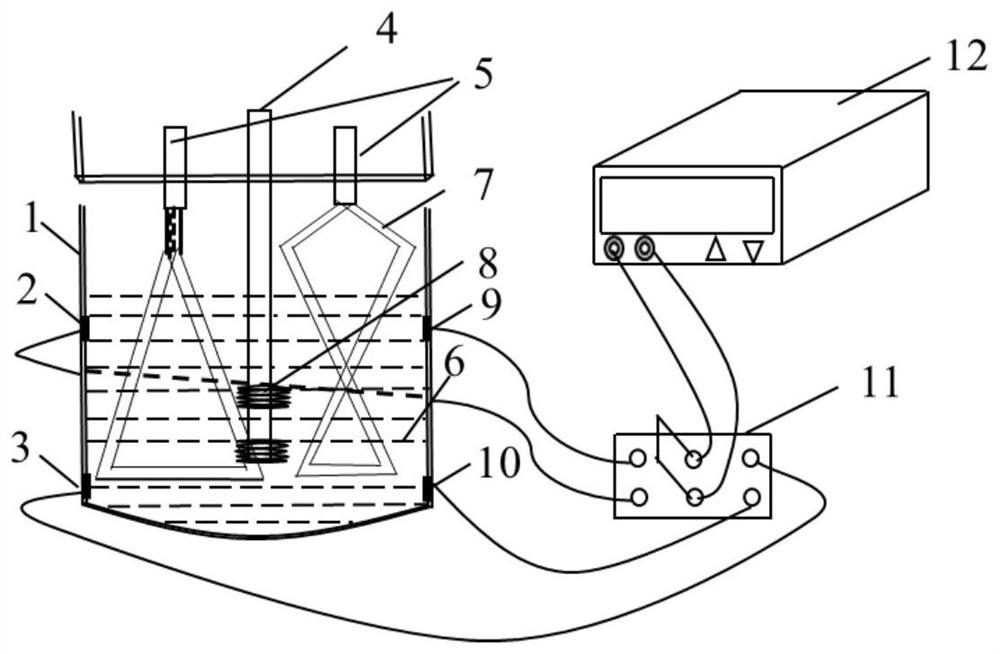

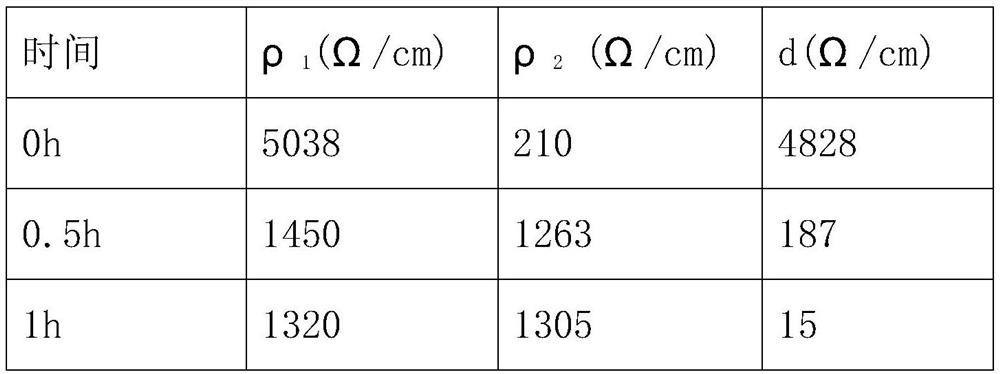

[0023] Example 1

[0024] S1, a first electrode group and a second electrode group are arranged on the inner wall of the mixing tank 1 of the mixing machine, wherein the first electrode group is located below the liquid level of the lithium-ion battery slurry 6, and is composed of a copper electrode 2 and a copper electrode 9, The second electrode group is located at the bottom of the mixing tank 1 of the mixing machine, and consists of a copper electrode 3 and a copper electrode 10. The first electrode group and the second electrode group are respectively connected to the resistance meter 12 through the double-pole double-throw switch 11; A dispersing shaft 4 and a stirring shaft 5 are arranged inside the stirring tank 1, a dispersing disc 8 is arranged at the lower end of the dispersion shaft 4, and a stirring paddle 7 is arranged at the lower end of the stirring shaft 5;

[0025] S2. Drive the dispersing plate 8 by the dispersing shaft 4 and the stirring paddle 7 by the sti...

Example Embodiment

[0031] Example 2

[0032] S1, a first electrode group and a second electrode group are arranged on the inner wall of the mixing tank 1 of the mixing machine, wherein the first electrode group is located below the liquid level of the lithium-ion battery slurry 6, and is composed of a copper electrode 2 and a copper electrode 9, The second electrode group is located at the bottom of the mixing tank 1 of the mixing machine, and consists of a copper electrode 3 and a copper electrode 10. The first electrode group and the second electrode group are respectively connected to the resistance meter 12 through the double-pole double-throw switch 11; A dispersing shaft 4 and a stirring shaft 5 are arranged inside the stirring tank 1, a dispersing disc 8 is arranged at the lower end of the dispersion shaft 4, and a stirring paddle 7 is arranged at the lower end of the stirring shaft 5;

[0033] S2. Drive the dispersing plate 8 by the dispersing shaft 4 and the stirring paddle 7 by the sti...

Example Embodiment

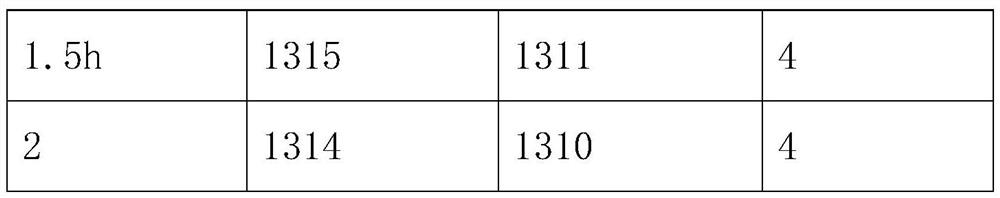

[0040] Example 3

[0041] S1, a first electrode group and a second electrode group are arranged on the inner wall of the mixing tank 1 of the mixing machine, wherein the first electrode group is located below the liquid level of the lithium-ion battery slurry 6, and is composed of a copper electrode 2 and a copper electrode 9, The second electrode group is located at the bottom of the mixing tank 1 of the mixing machine, and consists of a copper electrode 3 and a copper electrode 10. The first electrode group and the second electrode group are respectively connected to the resistance meter 12 through the double-pole double-throw switch 11; A dispersing shaft 4 and a stirring shaft 5 are arranged inside the stirring tank 1, a dispersing disc 8 is arranged at the lower end of the dispersion shaft 4, and a stirring paddle 7 is arranged at the lower end of the stirring shaft 5;

[0042] S2. Drive the dispersing plate 8 through the dispersing shaft 4, and drive the stirring paddle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com