A preparation method of phosphotungstic acid modified mofs derived porous carbon oxidation desulfurization catalyst

An oxidative desulfurization, phosphotungstic acid technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problem of poor catalytic reaction effect, difficult reaction process, etc. The complex manufacturing process and other problems can achieve the effects of good oxidative desulfurization performance, high recycling rate and sufficient drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

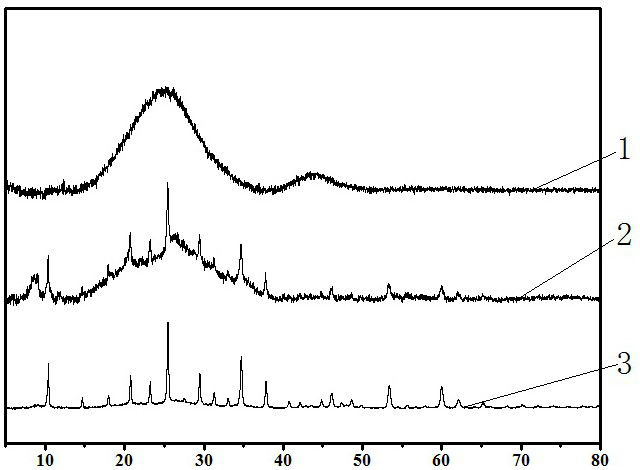

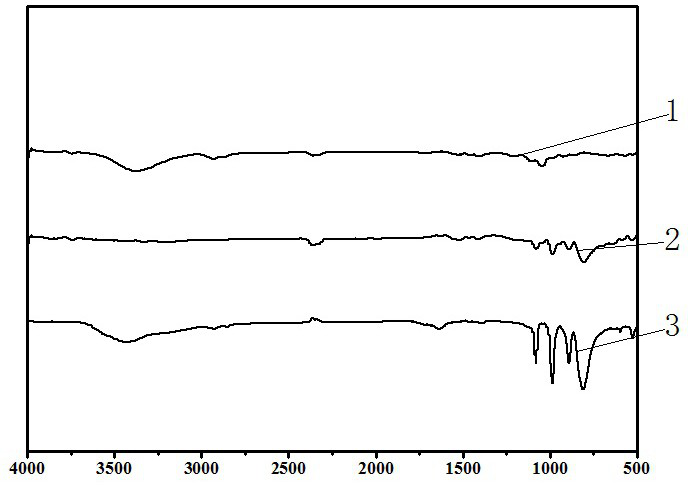

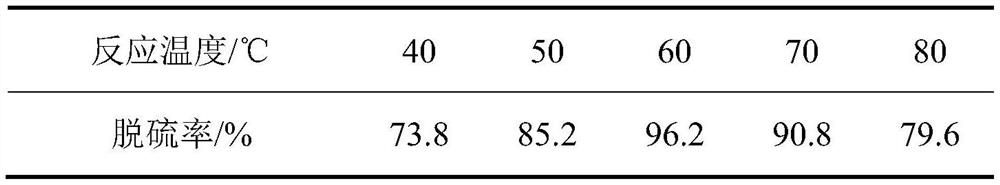

Embodiment 1

[0040] At room temperature, 0.81 g of 2-methylimidazole was added to the methanol solution, and stirred for 30 min to completely dissolve the 2-methylimidazole to obtain solution 1; 0.25 g of zinc nitrate hexahydrate was added to the methanol solution; The hydrated zinc nitrate was completely dissolved to obtain solution 2; under continuous stirring, the above solution 1 was slowly added to solution 2, and after stirring at room temperature for 24 hours, a large amount of milky white precipitate was obtained. After centrifugation, powdery ZIF- 8. Under the protection of an inert gas, the ZIF-8 prepared above was calcined at 500 °C to obtain a porous carbon material; 0.01 g of phosphotungstic acid was loaded into 0.1 g of the above prepared porous carbon material by an equal volume impregnation method. Then, the composite material was prepared; the composite material was placed in a vacuum drying oven and dried at 100 °C for 12 h to obtain HPW@ZC-1 type HPW@ZC oxidative desulfu...

Embodiment 2

[0042] At room temperature, 0.81 g of 2-methylimidazole was added to the methanol solution, and stirred for 30 min to completely dissolve the 2-methylimidazole to obtain solution 1; 0.25 g of zinc nitrate hexahydrate was added to the methanol solution; The hydrated zinc nitrate was completely dissolved to obtain solution 2; under continuous stirring, the above solution 1 was slowly added to solution 2, and after stirring at room temperature for 24 hours, a large amount of milky white precipitate was obtained. After centrifugation, powdery ZIF- 8. Under the protection of inert gas, the ZIF-8 prepared above was calcined at 600 °C to obtain a porous carbon material; a porous carbon material was obtained by using an equal volume impregnation method, and 0.01 g of phosphotungstic acid was loaded into 0.1 g of the porous carbon material prepared above. Then, the composite material was prepared; the composite material was placed in a vacuum drying oven and dried at 100 °C for 12 h to...

Embodiment 3

[0044] At room temperature, 0.81 g of 2-methylimidazole was added to the methanol solution, and stirred for 30 min to completely dissolve the 2-methylimidazole to obtain solution 1; 0.25 g of zinc nitrate hexahydrate was added to the methanol solution; The hydrated zinc nitrate was completely dissolved to obtain solution 2; under continuous stirring, the above solution 1 was slowly added to solution 2, and after stirring at room temperature for 24 hours, a large amount of milky white precipitate was obtained. After centrifugation, powdery ZIF- 8. Under the protection of an inert gas, the ZIF-8 prepared above was calcined at 700 °C to obtain a porous carbon material; 0.01 g of phosphotungstic acid was loaded into 0.1 g of the above prepared porous carbon material by an equal volume impregnation method. Then, the composite material was prepared; the composite material was placed in a vacuum drying oven and dried at 100 °C for 12 h to obtain HPW@ZC-3 type HPW@ZC oxidative desulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com