Cooked wheaten food machine with high noodle yield

A pasta machine, highly advanced technology, applied in the direction of dough mixer, dough extruder, food science, etc., can solve the problems of wasting flour, affecting the quality and taste of noodle making, unfavorable extrusion molding, etc., so as to avoid excessive mixing and improve once The effect of reducing the amount of noodle making and residual amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

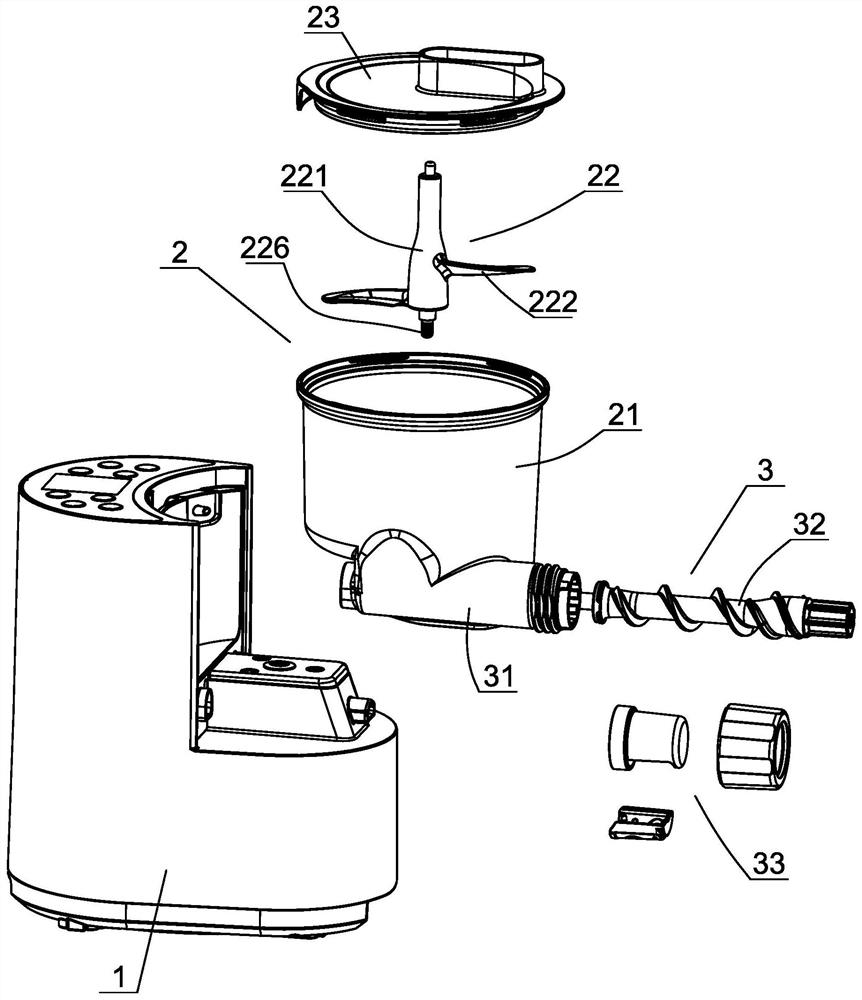

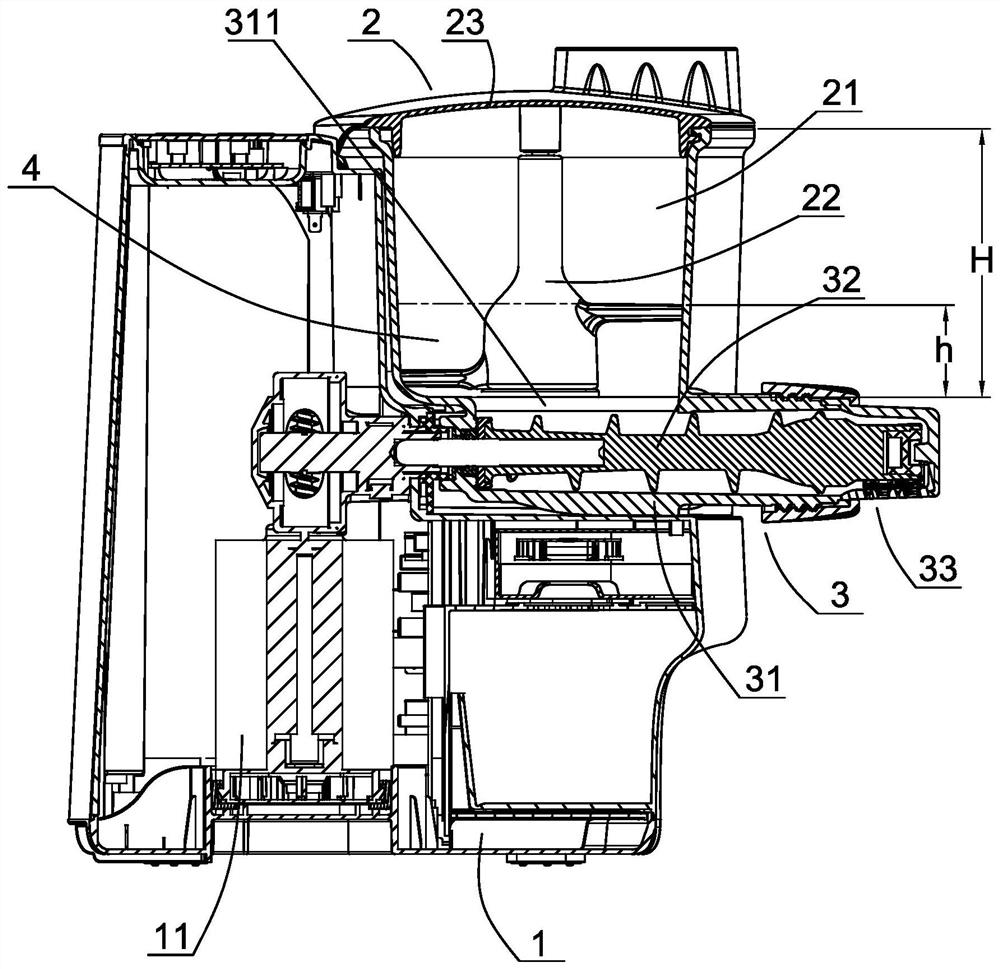

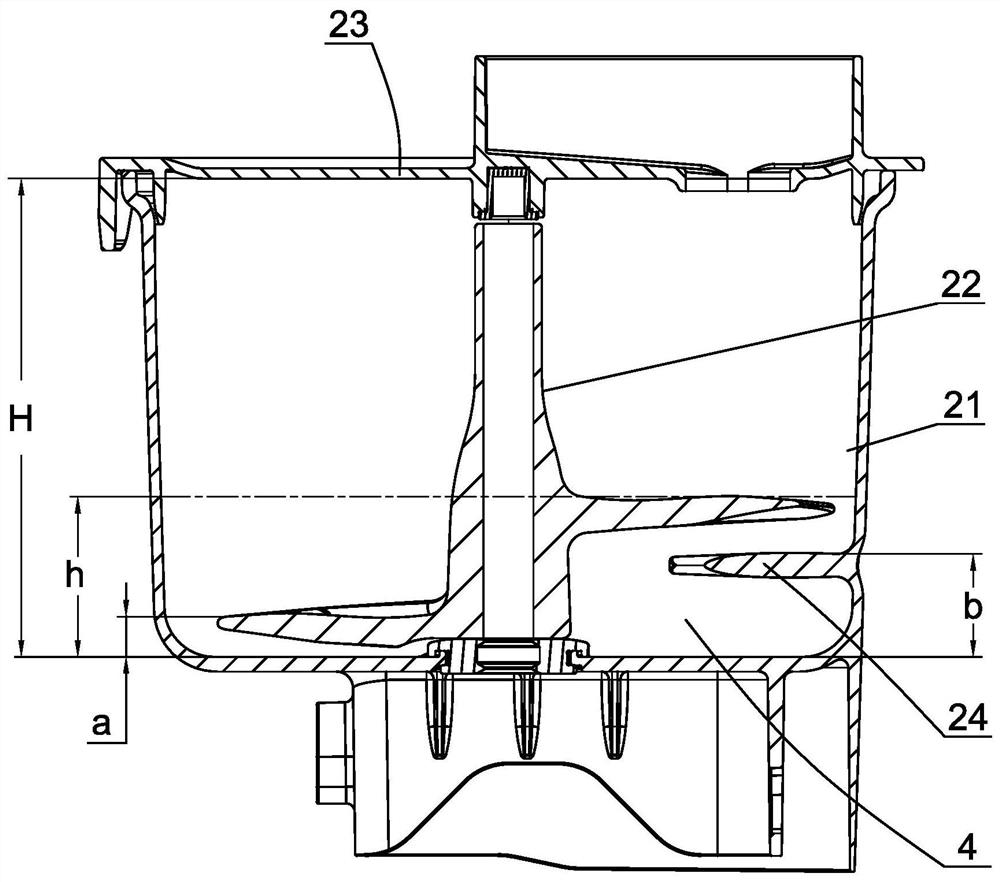

[0038] Such as figure 1 , figure 2 As shown, a kind of pasta machine with a high appearance rate includes a main engine 1 with a motor 11 inside, a stirring assembly 2 and an extruding assembly 3 arranged on the main engine, wherein the stirring assembly includes a stirring cup 21 with an upper opening, and is located at the stirring A stirrer 22 in the cup and an upper cover 23 covering the top of the stirring cup. The stirrer includes a stirring rod 221 and stirring teeth 222 arranged on the stirring rod, and one end of the stirring rod is a driving end 226 connected with a motor transmission. The extruding assembly comprises a dough extruding cylinder 31, a screw rod 32 arranged horizontally inside the extruding cylinder, a die head assembly 33 arranged at the opening end of the extruding cylinder, an inlet hole 311 is formed at the joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com