Front-end electronic equipment fault detection and intelligent maintenance application management system

A front-end electronic and intelligent maintenance technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as inability to record and track, inability to maintain in time, and system equipment failure records that cannot be tracked and traced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

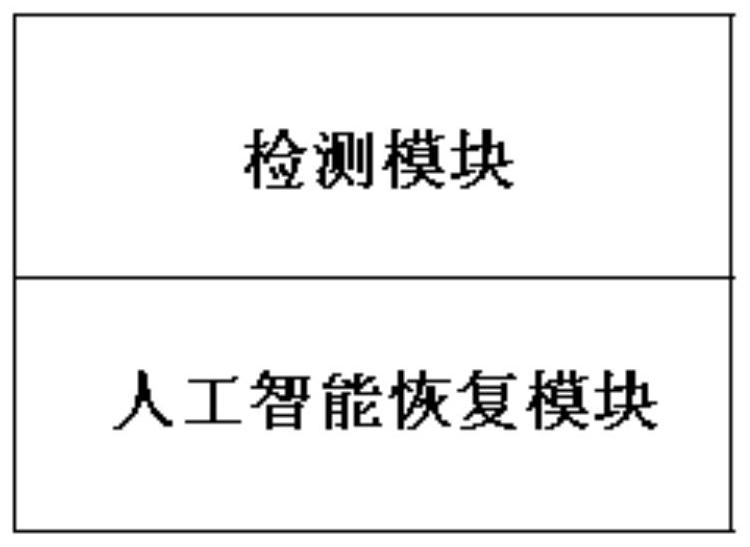

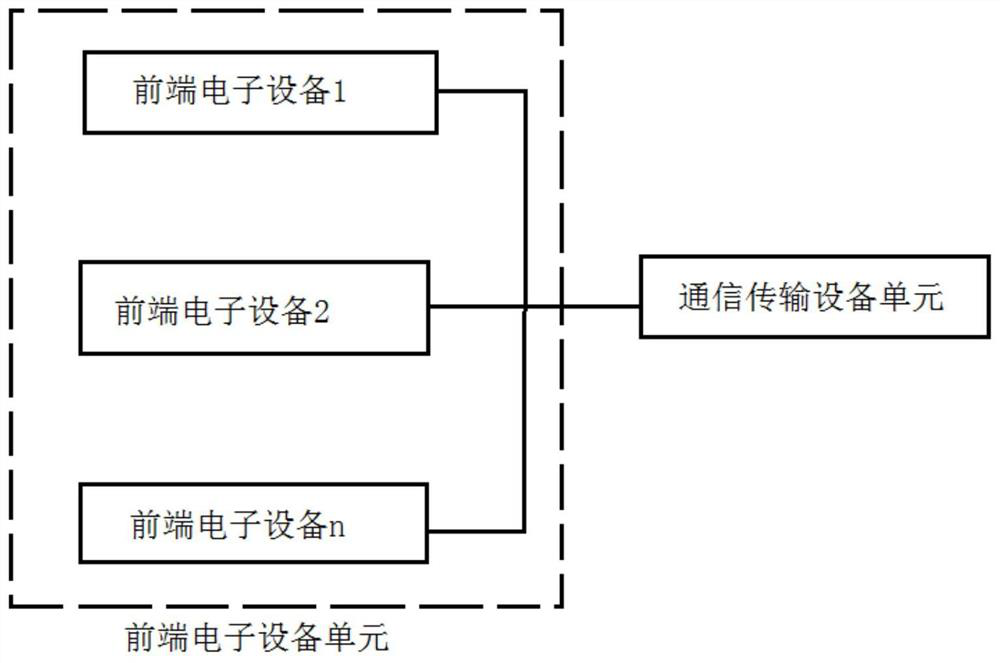

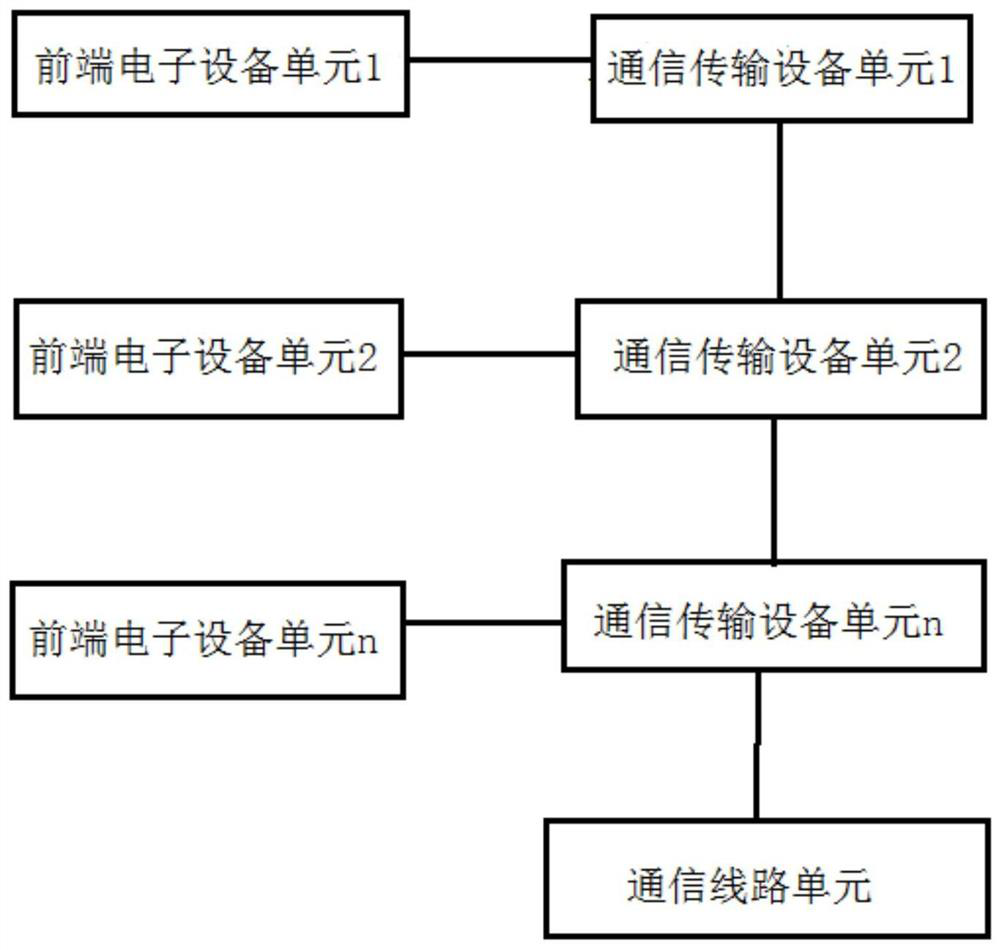

[0043] Such as Figure 1-3 As shown, a front-end electronic equipment fault detection and intelligent maintenance application management system includes a front-end electronic equipment unit, a communication transmission equipment unit, a communication line unit, a communication transmission receiving unit and a computer management platform; the front-end electronic equipment unit, communication transmission The equipment unit, the communication line unit, the communication transmission receiving unit and the computer management platform are sequentially connected; the communication transmission equipment unit is composed of communication transmission equipment and an embedded detection component, and the embedded detection component includes a detection module, and the detection module connects the front-end electronic equipment unit Working status information detection and processing, detects the working status information of the front-end electronic equipment unit, and trans...

Embodiment 2

[0046] It is basically the same as Embodiment 1, the difference is: the embedded detection component also includes an artificial intelligence recovery module, and the embedded detection component detects and processes the working state information of the front-end electronic equipment unit through the detection module. In the case of status information, the abnormal working status information is grouped into codes to form fault codes, and the artificial intelligence recovery module performs corresponding processing on the fault codes, so that when the fault codes appear in the front-end electronic equipment unit, it is automatically controlled by the artificial intelligence recovery module to restart and reset until the front-end The electronic equipment unit can output normal working state information to achieve normal state operation. It can be automatically repaired by the artificial intelligence recovery module so that the front-end electronic equipment unit can output norm...

Embodiment 3

[0048] It is basically the same as Embodiment 2, the difference is: the detection module detects that the abnormal working state information group code is a fault code, and after the reset process is restarted by the artificial intelligence recovery module, when the front-end electronic equipment unit is still in the abnormal working state, the communication The transmission equipment unit transmits the fault code to the computer management platform to give an alarm prompting that the reset fails, and prompts manual processing. When the artificial intelligence recovery module cannot automatically restore the front-end electronic equipment unit to a normal working state, it can promptly prompt the computer management platform to arrange manual processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com