Flexible mineral insulated cable construction method

A technology of mineral insulated cables and construction methods, which is applied in the direction of cable laying equipment, etc., can solve the problems of increasing project costs and failure to meet fire protection requirements at branches, and achieve the effects of simple construction, promotion of construction progress and project quality, and resolution of fire protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

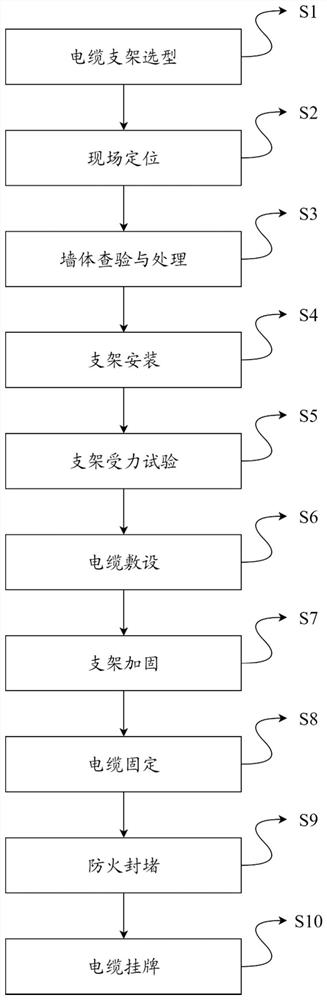

[0033] Refer to attached figure 1 As shown, the present invention provides a technical solution: a flexible mineral insulated cable construction method, comprising the following steps:

[0034] S1, cable support type selection, choose horizontal laying cable support and vertical laying cable support according to drawing design requirements and actual site conditions;

[0035] Specifically, 50*5 angle steel is used for fixing the horizontally laid cable bracket and the top surface, and fixed on the ceiling with expansion bolts, and DN25 galvanized steel pipe is used for the vertical pole and horizontal support pole to reduce the sliding of the cable during the horizontal laying process Friction, according to the number of cables, make horizontal support rods with different layers. The vertical rods, horizontal rods and angle steel are firmly welded. (triangular structure), fixed on the wall along the wall, anti-rust treatment on the welded part after production, and the color ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com