Magnetic levitation driving device based on linear doubly-fed motor and magnetic levitation train system

A technology of maglev train and double-fed motor, applied in the field of maglev, can solve the problems of increasing system cost, reducing system reliability, etc., and achieving the effect of reducing system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

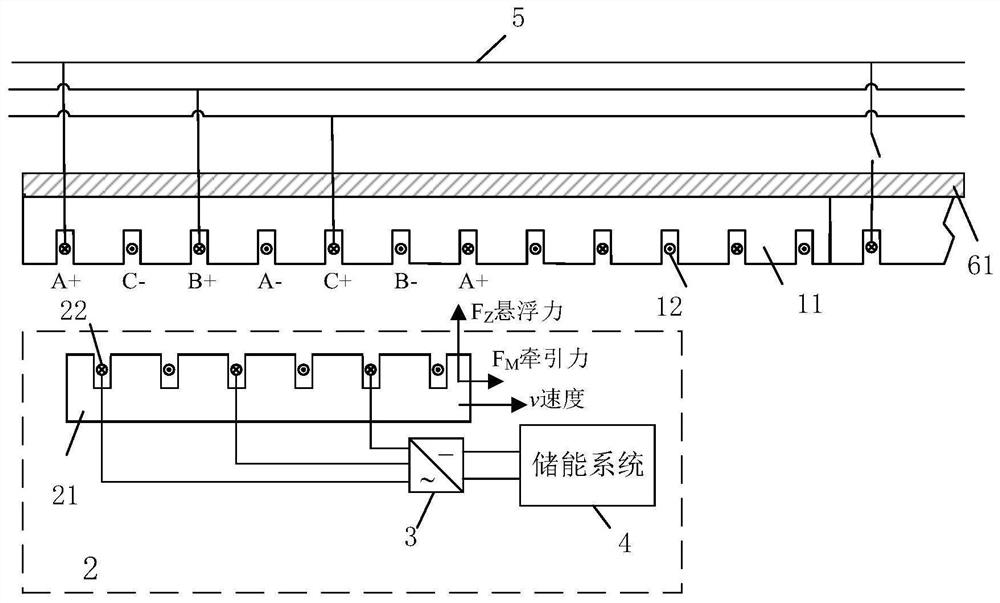

[0029] Such as figure 1 As shown, this embodiment provides a magnetic levitation drive device based on a linear double-fed motor. The linear double-fed motor includes a linear double-fed motor stator 1 and a linear double-fed motor mover 2. The linear double-fed motor stator 1 includes a stator core 11 and stator winding 12, the linear doubly-fed motor mover 2 includes a mover iron core 21 and a mover winding 22, the stator winding 12 of the linear doubly-fed motor stator 1 is connected to the traction substation through a feeder cable 5, and the linear doubly-fed motor generates The thrust is used to provide traction in the horizontal direction, and the normal force generated by the stator 1 of the linear double-fed motor and the mover 2 of the linear double-fed motor is used to provide the suspension force in the vertical direction. An energy storage structure that collects and stores electric energy. The electric energy includes electric energy transmitted from the stator 1...

Embodiment 2

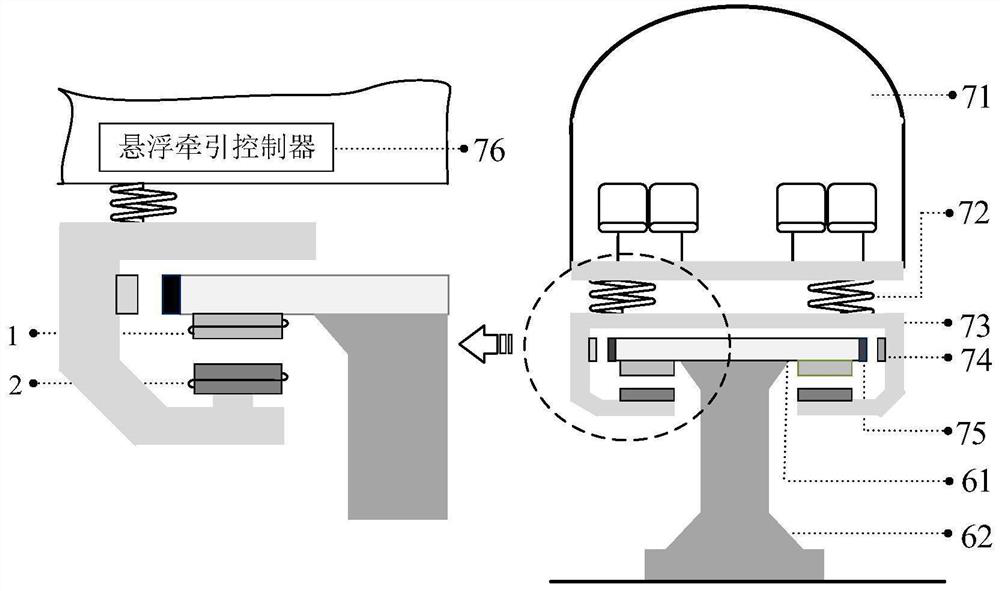

[0036] Such as figure 2 As shown, the present embodiment provides a kind of magnetic levitation train system, comprises magnetic levitation train and track 61, and track 61 is laid on the top of base 62, and magnetic levitation train comprises compartment 71, bogie 73, and bogie 73 is positioned at compartment 71 below and passes air spring 72 connection, the two sides of the track 61 are provided with an action plate 75, and correspondingly, a guiding electromagnet 74 is provided on the bogie 73 relative to the position of the action plate 75, and the system also includes a magnetic levitation drive device based on a linear doubly-fed motor. In this embodiment The magnetic levitation driving device based on the linear doubly-fed motor is the same as that in Embodiment 1, and its specific composition and structure will not be repeated in this embodiment. The linear double-fed motor stator 1 is set and laid under the track 61, the linear double-fed motor mover 2 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com