Conveying positioning device for sagger visual inspection

A visual inspection and positioning device technology, applied in the direction of conveyor objects, transportation and packaging, optical testing defects/defects, etc., can solve the problems of peeling and slag, waste of defective materials, misjudgment and missed judgment, etc., to achieve the goal of conveying High efficiency, the effect of improving the overall production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described below by way of examples, but the present invention is not limited to the scope of the described examples.

[0031]

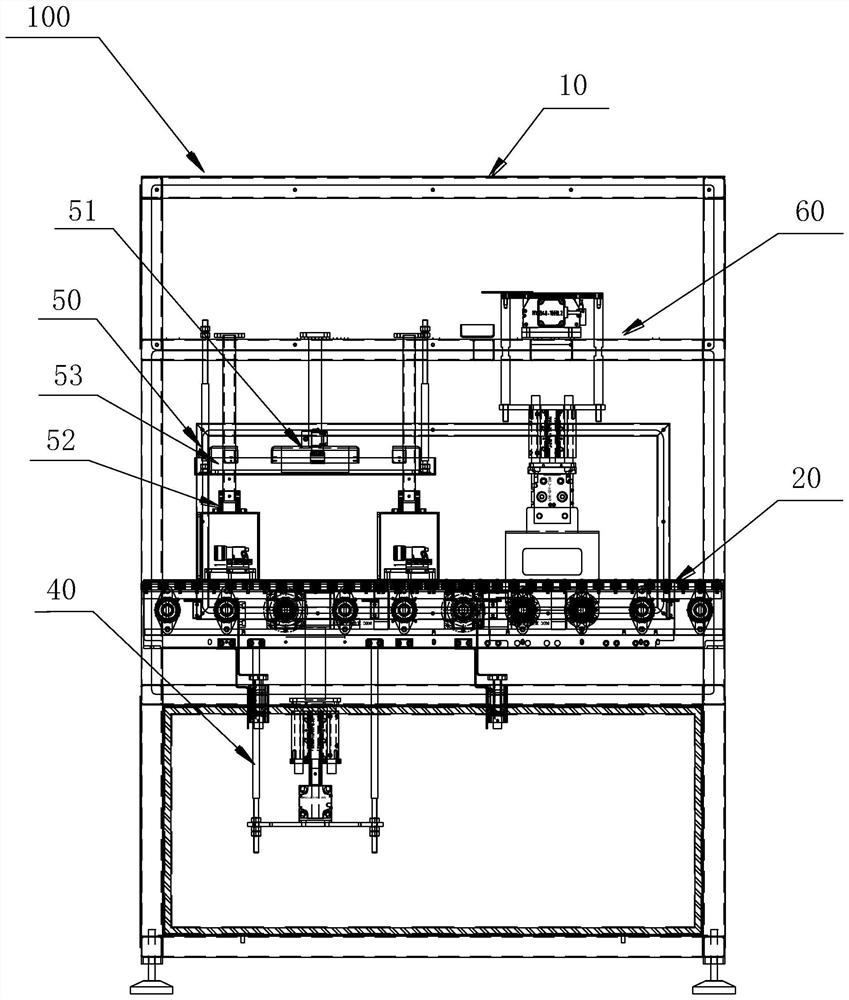

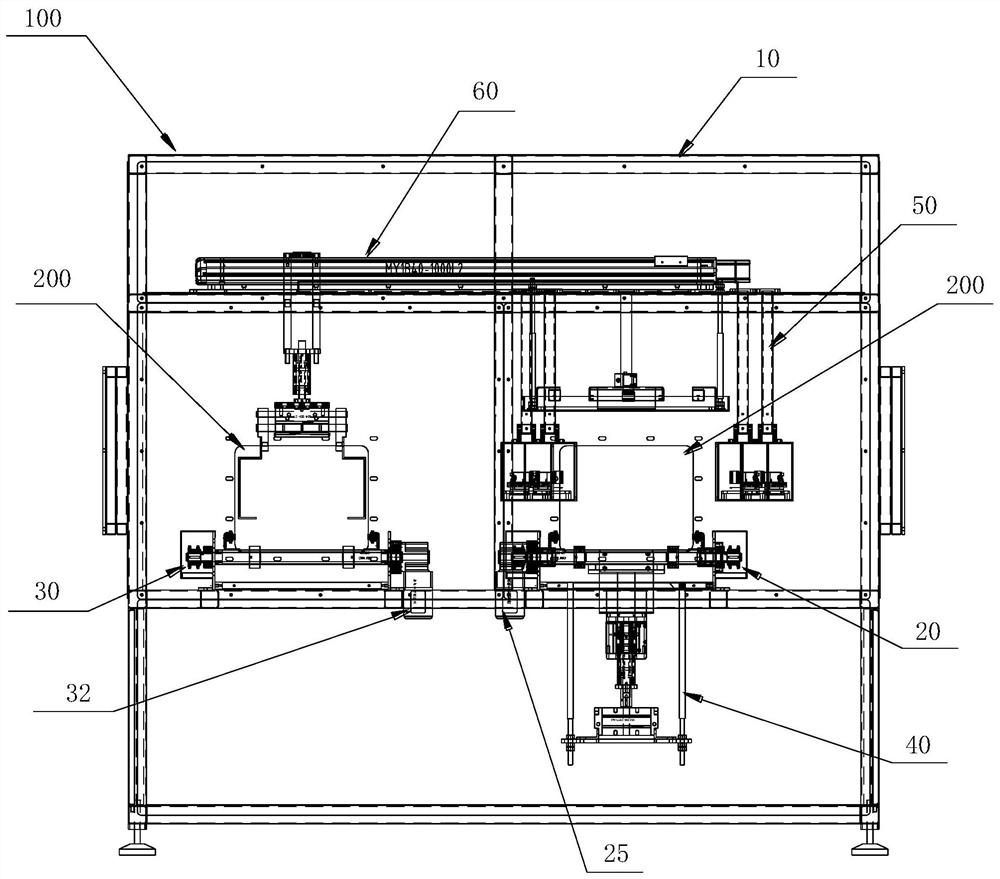

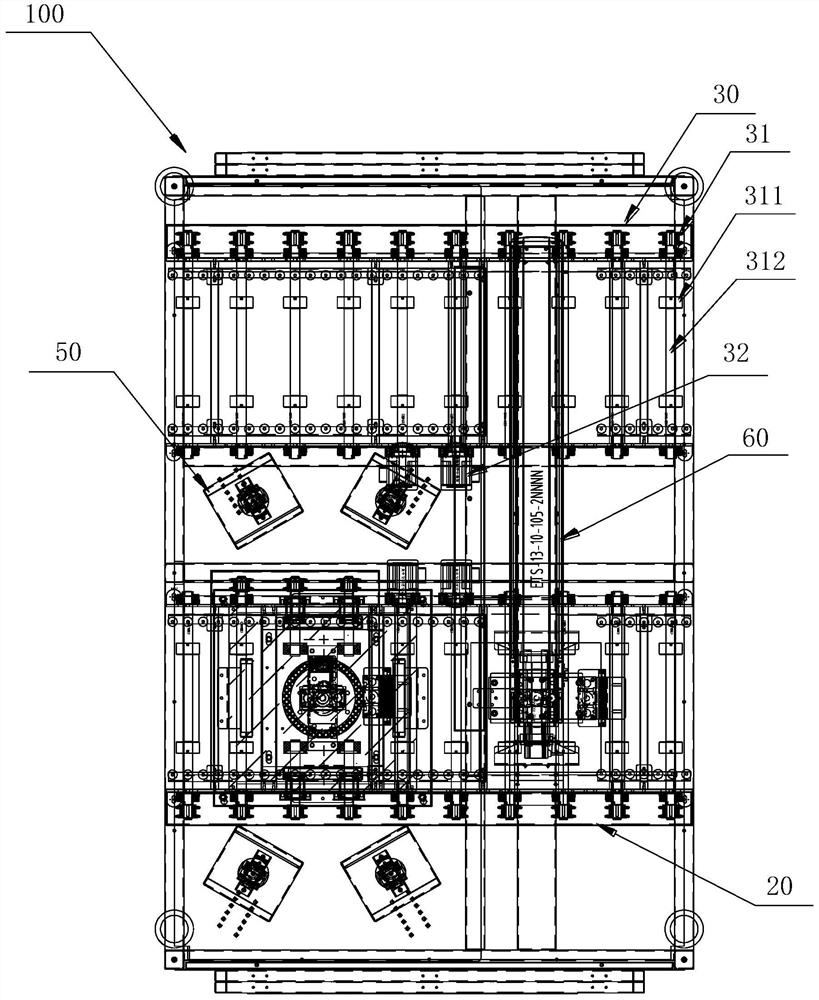

[0032] like Figures 1 to 10 As shown, this embodiment discloses a saggar visual inspection equipment 100, which is mainly used for special equipment for crack detection and rejection of the saggar 200 used for special materials. Crack detection, defect detection, peeling and slag detection, and bulk residue detection are carried out in the bowl, so as to remove the unqualified saggars 200. The whole detection and rejection process is fast, efficient, and precisely controlled. Especially when detecting the AB bowl, it can also perform the filling operation. Based on this, after the saggar visual inspection device 100 is applied in an automated production line, for example, an entire automated assembly line is formed by supporting a bowl filling machine, a shaker, a bowl stacking machine, a conveyor, etc., whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com