Toner filling method

A toner and filling technology, applied in the field of skin care, can solve problems such as the inability to improve the filling line, the reduction of toner production efficiency, and the reduction of enterprise economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

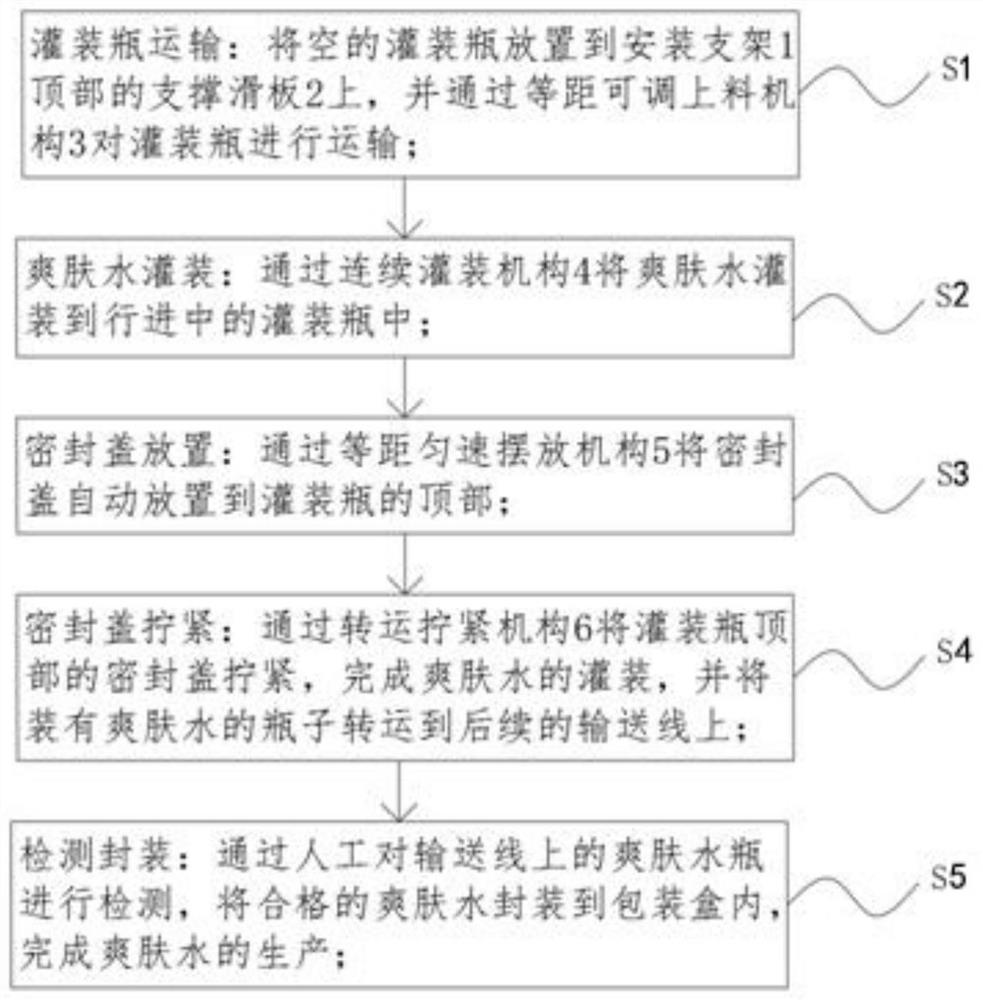

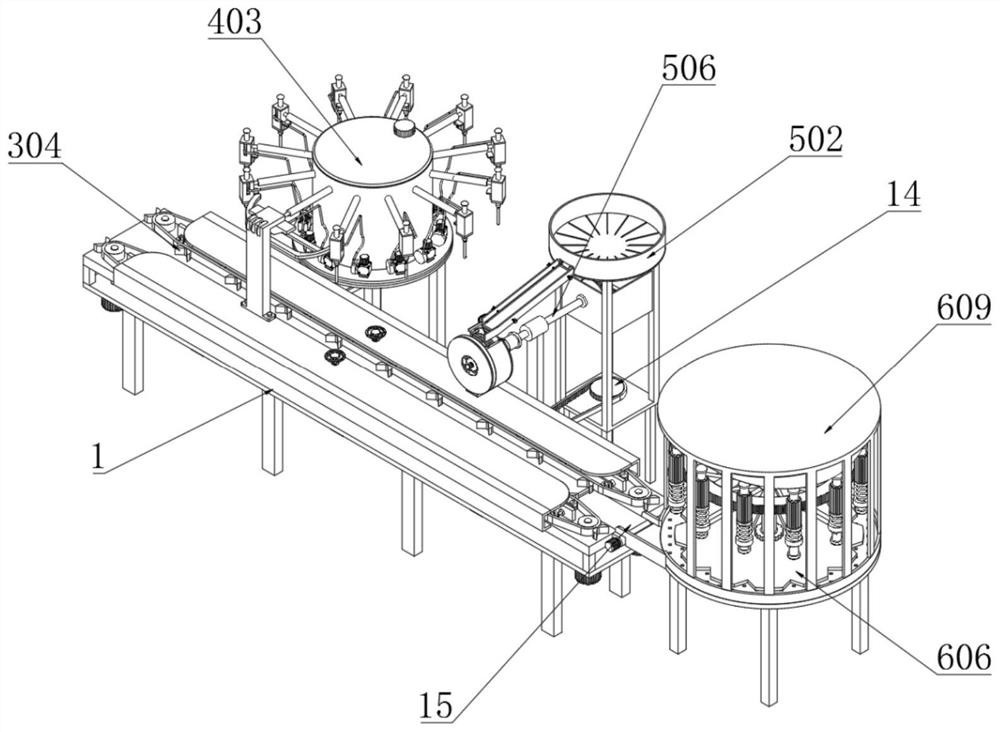

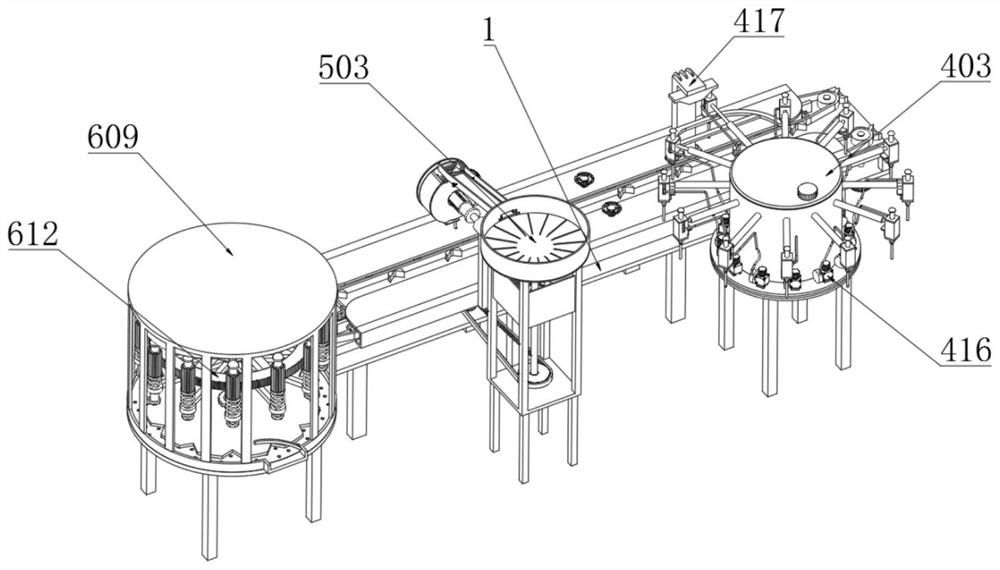

[0036] Example: such as figure 1 Shown, the filling of toner comprises the following steps:

[0037] S1. Filling bottle transportation: place the empty filling bottle on the support slide 2 on the top of the installation bracket 1, and transport the filling bottle through the equidistant adjustable feeding mechanism 3;

[0038] S2, skin toner filling: the toner is filled into the moving filling bottle through the continuous filling mechanism 4;

[0039] S3. Placement of the sealing cap: the sealing cap is automatically placed on the top of the filling bottle through the equidistant and uniform placement mechanism 5;

[0040] S4. Tighten the sealing cap: tighten the sealing cap on the top of the filling bottle through the transfer tightening mechanism 6 to complete the filling of the toner, and transfer the bottle containing the toner to the subsequent conveying line;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com