Preparation method of reprogrammable driving micro-column array

A micro-pillar array and reprogramming technology, applied in the field of composite materials, can solve the problems of inability to meet bending response requirements, unfavorable practical applications, and low reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

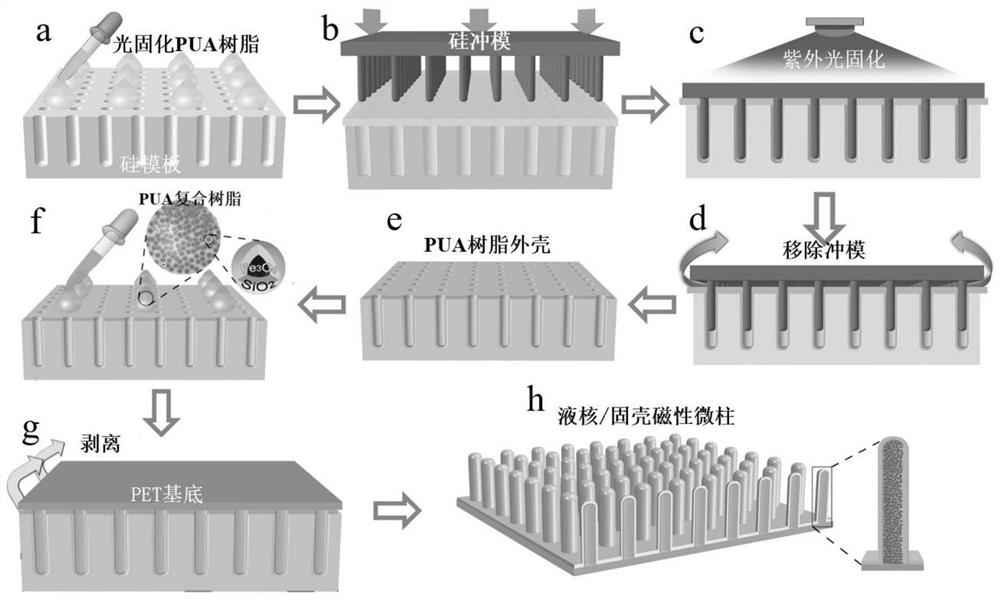

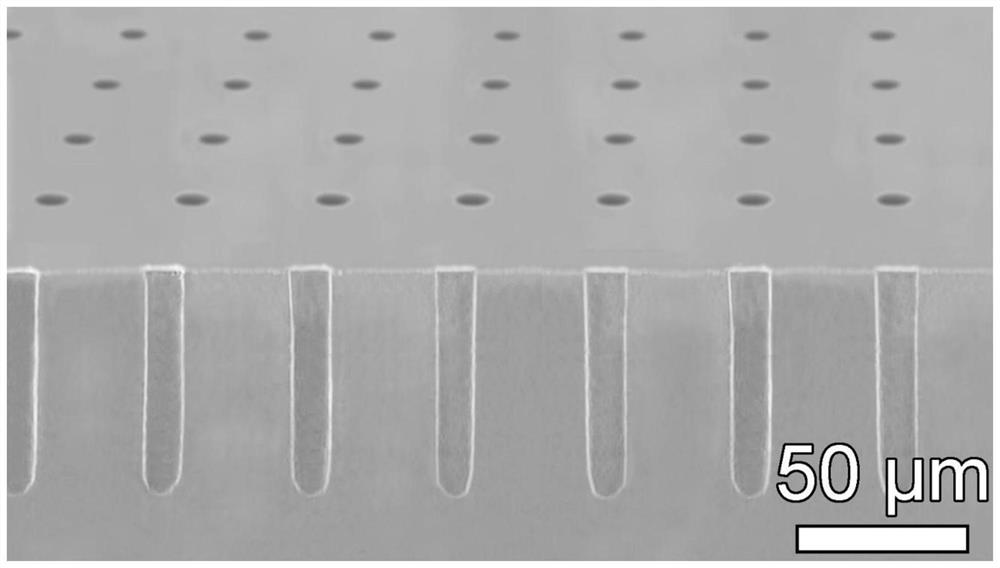

[0039] Step 1: Drop the PUA resin mixed with the photoinitiator-4-hydroxybenzophenone (HBP) onto the silicon template with a regular micron-sized column cavity (column cavity diameter 5 μm, depth 40 μm, spacing 20 μm), through a vacuum The assisted molding process penetrated into the column cavity of the template to form product I, and the cross-sectional image of the silicon template is shown in the attached figure 2 ;

[0040] Step 2: Punch a silicon die with regular micron-sized microcolumns (microcolumn diameter 3 μm, height 39 μm, microcolumn spacing 22 μm, one-to-one correspondence between microcolumn and column cavity) onto the template, discharge part of the resin in the column cavity, and the column The remaining resin in the cavity wraps the micropillars on the die to form Product II. For a cross-sectional image of the silicon die, see attached image 3 ;

[0041] Step 3: irradiate the product II with ultraviolet light, and the resin covering the micropillars on t...

Embodiment 2

[0049] The steps of embodiment 2 are the same as those of embodiment 1, except that the mass fraction of magnetic nanoparticles in the composite resin in step 5 is 10-30%.

Embodiment 3

[0051] Embodiment 3 is identical with embodiment 1 step, and difference is: in step 5, magnetic particle is Fe, Fe 2 o 3 , Fe 3 o 4 , one or more of Co and Ni.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com