Automatic Z-direction fiber implantation device for composite material preform

A technology of composite materials and implanted devices, which is applied in the direction of textiles, papermaking, braided fabrics, weight reduction, etc., can solve the problems of expensive labor costs, high labor intensity, and low production efficiency, so as to improve the quality and efficiency of forming, and improve work efficiency. Efficiency, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with specific embodiments.

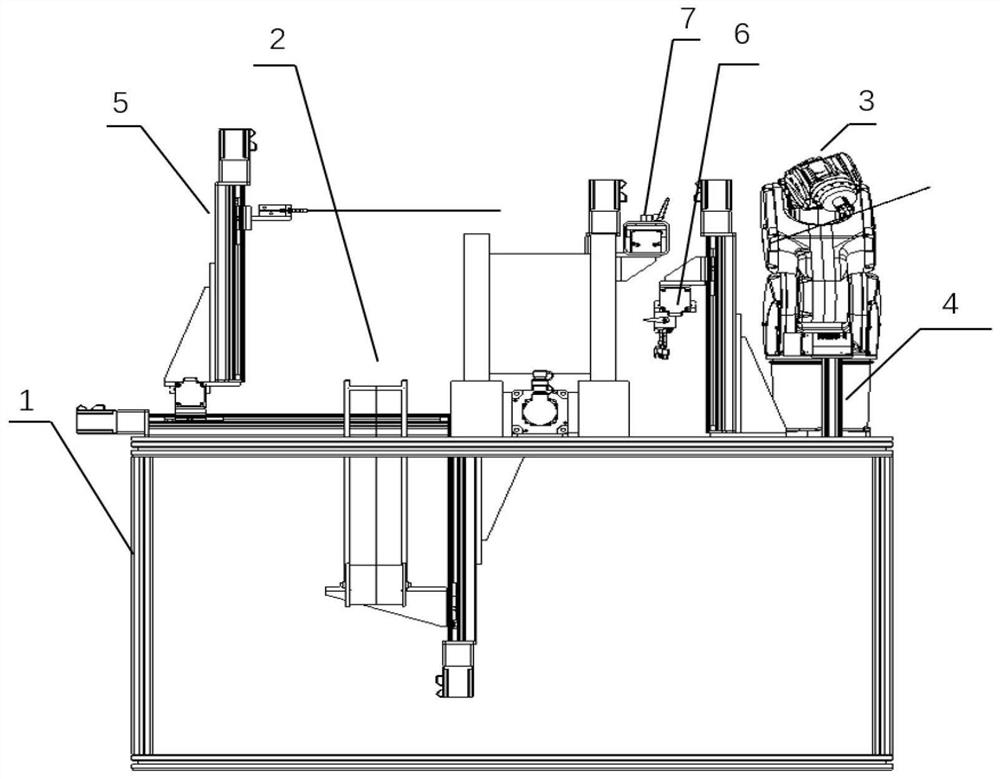

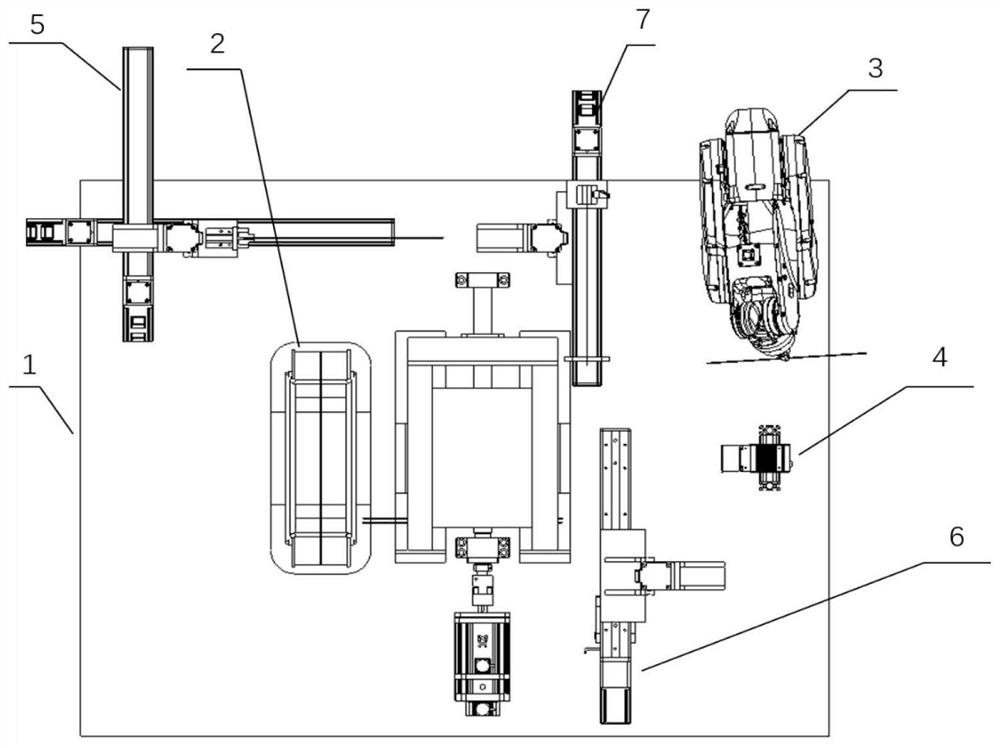

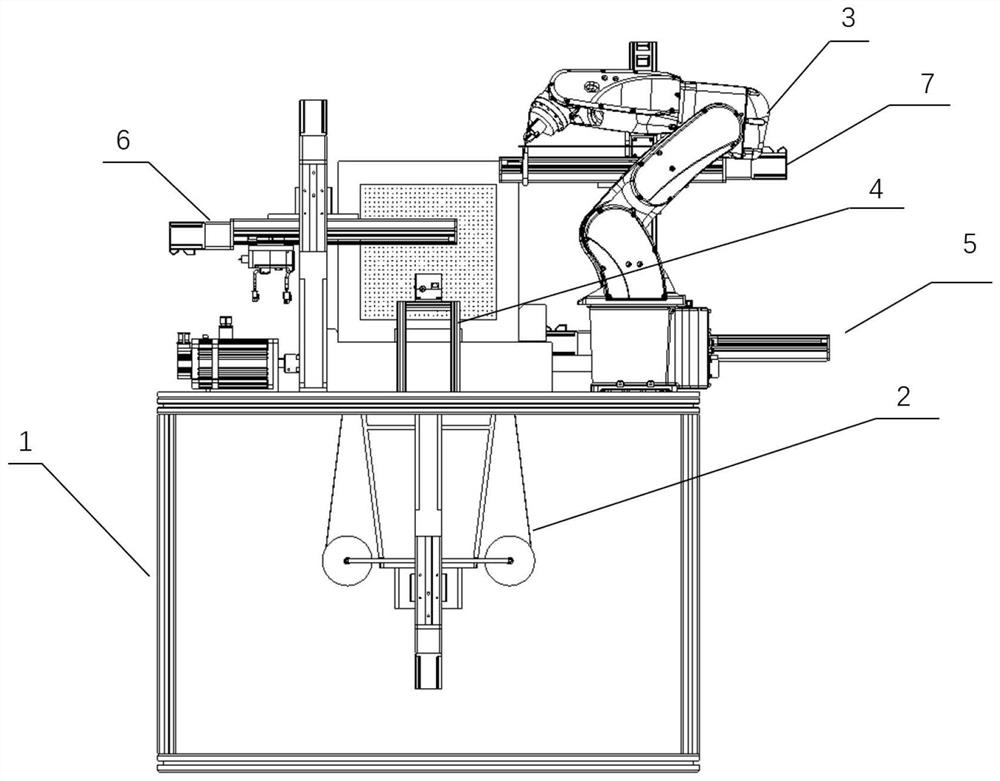

[0036] Such as Figure 1 to Figure 8 As shown, for prefabricated bodies of different sizes, the minimum array needle diameter is 1.2 mm, and the minimum array needle center distance is 2.4 mm. A Z-direction fiber replacement method and device are designed, including a workbench 1 and a yarn lifting mechanism 2; Yarn needle conveying mechanism 3, visual positioning mechanism 4, array steel needle clamping mechanism 5, wire loop forming mechanism 6, metal rod conveying mechanism 7, said workbench 1 includes workpiece clamping mechanism 101, servo motor 102, bearing 103, The yarn lifting mechanism 2 includes a mobile module 201, a yarn roller 202, the yarn replacement needle delivery mechanism 3 includes a mechanical arm structure 301, a yarn replacement needle clamping mechanism 302, and a yarn replacement needle 303, and the visual positioning mechanism 4 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com