Preparation method of light flame-retardant ecological island roadbed material

A roadbed material, flame-retardant technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of tediousness, design, and complex composition of foam lightweight soil, and achieve the effect of simple preparation process and ensuring flame-retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

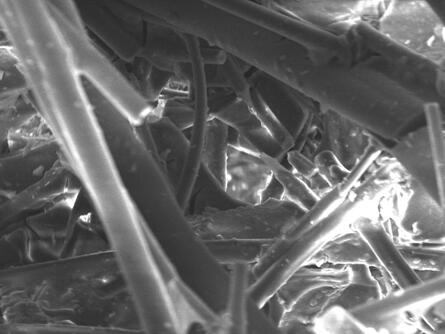

Image

Examples

Embodiment 1

[0015] A method for preparing a lightweight flame-retardant ecological sea-island subgrade material, the preparation process comprising the following steps:

[0016] (1) Dissolve polycrystalline mullite fibers in water and shear them with a fiber grinder. The mass ratio of fibers to water is 1:30, and the shearing time is 4 minutes. The length is 600 μm and the aspect ratio is 60:1. Chopped mullite fiber;

[0017] (2) Add 0.6wt% polyacrylamide powder (surfactant) to the slurry obtained in step (1), and disperse for 3 minutes at a speed of 1500r / min;

[0018] (3) Remove the slurry obtained in step (2) from the mixer, pour it into a mold, and naturally settle and form it under the action of gravity;

[0019] (4) Demould the green body obtained after molding in step (3), and place it in an air-blast drying oven at 80°C for 4 hours to obtain a lightweight porous fiber-based composite material.

Embodiment 2

[0021] A method for preparing a lightweight flame-retardant ecological sea-island subgrade material, the preparation process comprising the following steps:

[0022] (1) Dissolve polycrystalline mullite fibers in water and shear them with a fiber pulverizer. The mass ratio of fibers to water is 1:50, and the shearing time is 8 minutes. The length is 400 μm and the aspect ratio is 40:1. Chopped mullite fiber;

[0023] (2) Add 0.4wt% polyacrylamide powder (surfactant) to the slurry obtained in step (1), and disperse at a speed of 1000r / min for 1min;

[0024] (3) Remove the slurry obtained in step (2) from the mixer, pour it into a mold, and naturally settle and form it under the action of gravity;

[0025] (4) Demould the green body obtained in step (3), and place it in a blast drying oven at 100°C for 2 hours to obtain a lightweight porous fiber-based composite material.

Embodiment 3

[0027] A method for preparing a lightweight flame-retardant ecological sea-island subgrade material, the preparation process comprising the following steps:

[0028] (1) Dissolve polycrystalline mullite fibers in water and shear them with a fiber pulverizer. The mass ratio of fibers to water is 1:40, and the shearing time is 6 minutes to obtain a fiber with a length of 500 μm and an aspect ratio of 50:1 chopped mullite fiber;

[0029] (2) Add 0.5wt% polyacrylamide powder (surfactant) to the slurry obtained in step (1), and disperse for 2 minutes at a speed of 1250r / min;

[0030] (3) Remove the slurry obtained in step (2) from the mixer, pour it into a mold, and naturally settle and form it under the action of gravity;

[0031] (4) Demould the green body obtained in step (3), and place it in a blast drying oven at 90°C for 3 hours to obtain a lightweight porous fiber-based composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com