River channel sludge cleaning device

A cleaning device and river silt technology, which is applied in the direction of earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve the problems of poor dredging effect and inability to ensure effective cleaning of silt deep in the river bed , to achieve the effect of ensuring quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

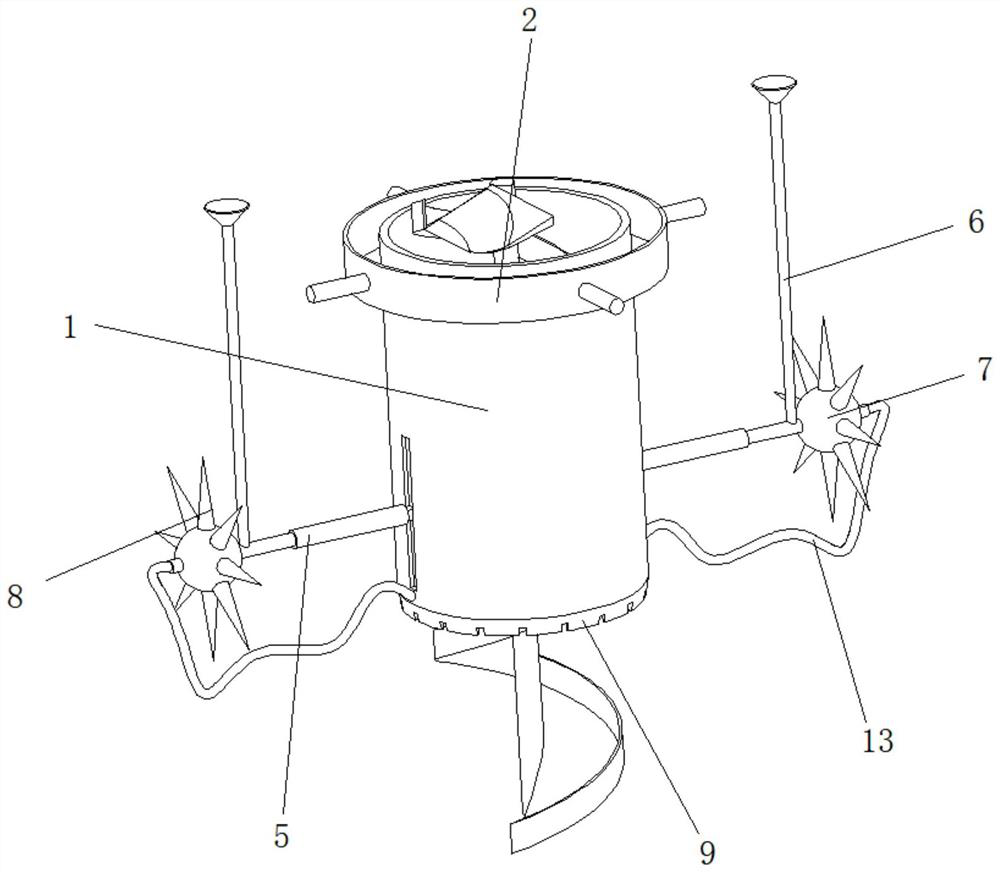

[0038] Such as Figure 1-4 As shown, the present invention provides a technical solution: a river channel silt cleaning device, including a cleaning limiting barrel 1, the top of the cleaning limiting barrel 1 is fixedly connected with a driving disc 2, and the top of the driving disc 2 is fixedly connected with a storage inner Groove 3, the vertical middle position inside the cleaning and limiting barrel 1 is provided with a coupling drive mechanism 4, and the external sides of the cleaning and limiting barrel 1 and the positions near the bottom are slidingly connected with the driving auxiliary mechanism 5, and the input end of the driving auxiliary mechanism 5 is fixed. Connected with a liquid level air guide tube 6, the drive auxiliary mechanism 5 is fixedly connected to the outer side of one end away from the cleaning restriction barrel 1. A walking ball 7 is fixedly connected to the outer surface of the walking ball 7. The outer surface of the walking ball 7 is uniformly ...

Embodiment 2

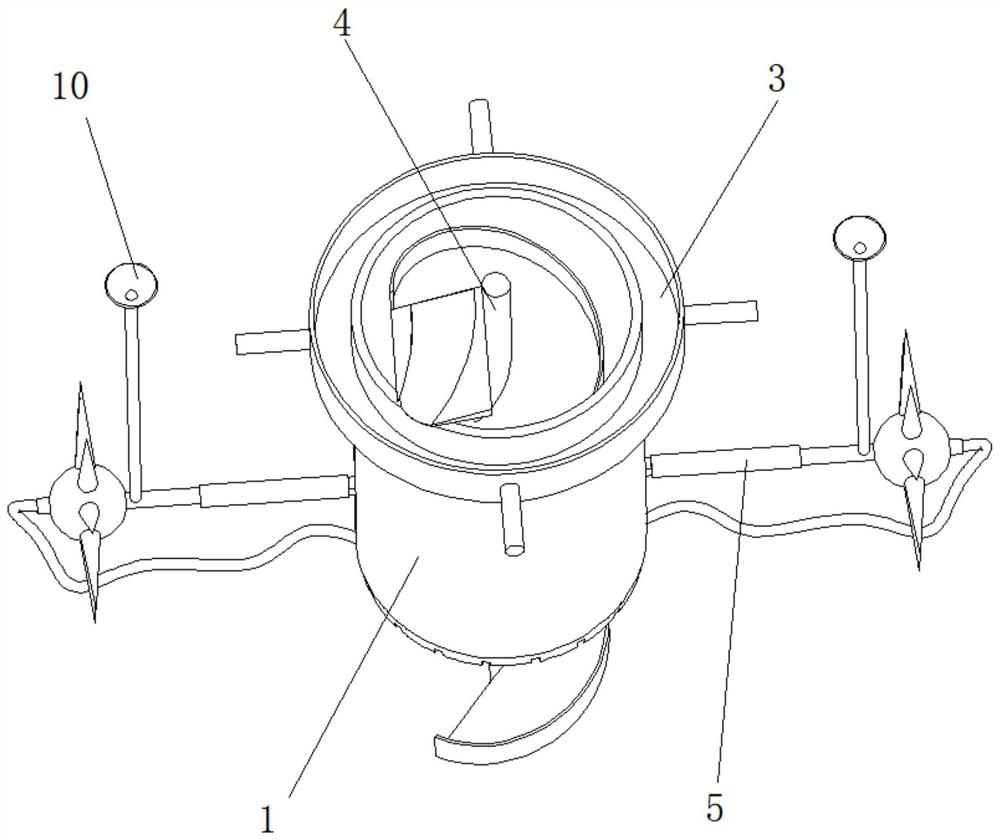

[0042] Such as Figure 5-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a river channel silt cleaning device, the coupling drive mechanism 4 includes a cleaning rotary shaft 41, and the outer surface of the cleaning rotary shaft 41 is fixedly connected with a guide vane 42 , the outer surface of the guide vane 42 is fixedly connected with a limiting side baffle 43 .

[0043] Clean the outer upper surface of the rotating shaft 41 and be located in the middle of the guide vane 42 to be provided with a spiral chute 44, the inside of the spiral chute 44 is slidably connected with a moving slider 45, and the outer side of the moving slider 45 is fixedly connected with a transmission connecting rod 46 One end of the transmission link 46 away from the moving slider 45 is fixedly connected to the lower position inside the cleaning restriction barrel 1 .

[0044] The top of the cleaning rotary shaft 41 is fixedly connected with a materia...

Embodiment 3

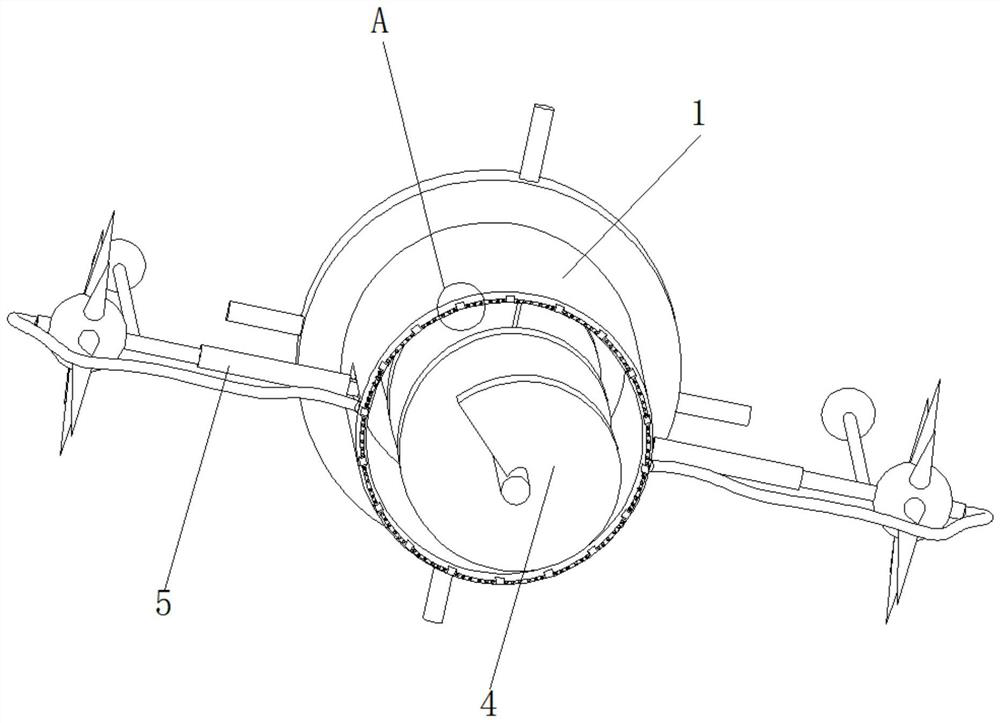

[0046] Such as Figure 8 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a river channel silt cleaning device, the driving auxiliary mechanism 5 includes a supporting driving rod 51, and the left side of the supporting driving rod 51 is connected with the cleaning device. Limit the surface sliding connection of the barrel 1, the right side of the inside of the support drive rod 51 is fixedly connected with an auxiliary plug 52, the inside of the auxiliary plug 52 runs through and is threadedly connected with a reciprocating screw rod 53, the right side of the reciprocating screw rod 53 is connected to the walking ball 7 fixed connectivity.

[0047] The inside of the reciprocating screw rod 53 is provided with a boost chamber 54, the left side of the support drive rod 51 is fixedly connected with a support insert rod 55, and the right end of the support insert rod 55 is fixedly connected with a sealing slider 56, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com