Pipeline dredging device for smart city construction

A technology for urban construction and desilting equipment, applied in water supply equipment, cleaning sewer pipes, buildings, etc., can solve the problems of pipelines with different diameters, troublesome operation, low efficiency of manual excavation, etc., and achieve better removal effect Good, easy to scrape off, good sludge removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

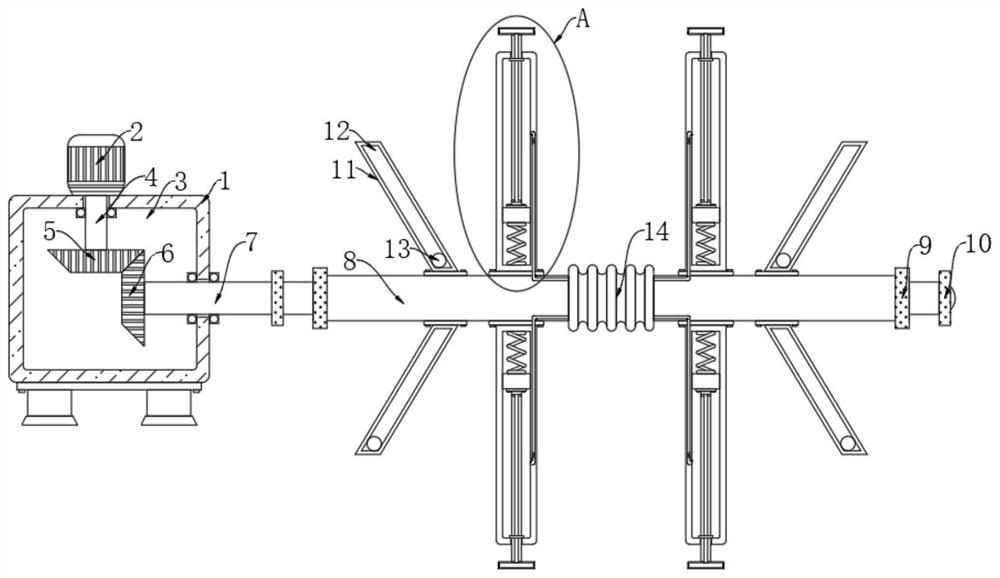

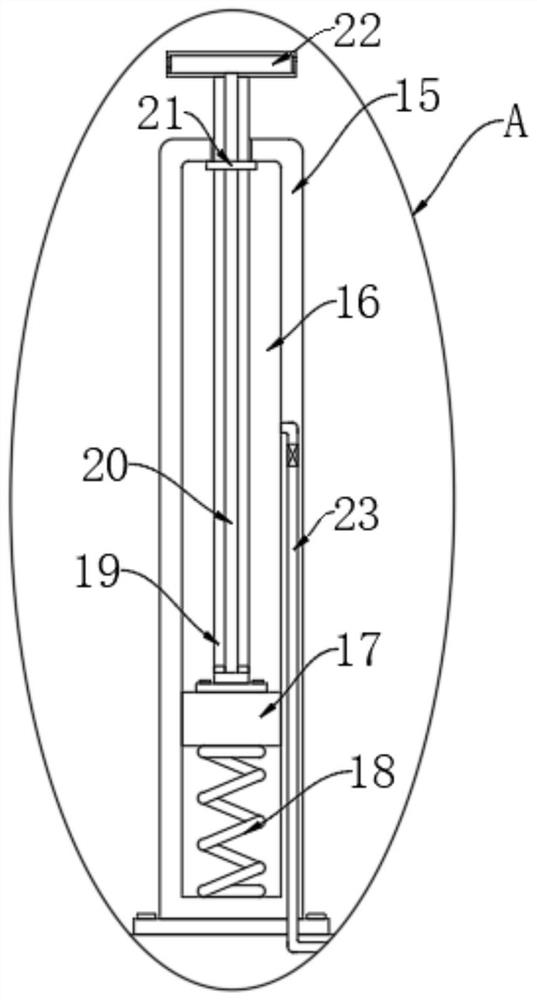

[0025] refer to Figure 1-4 , a pipeline dredging device for smart city construction, comprising a housing 1, a rotating chamber 3 is provided in the housing 1, a motor 2 is installed above the housing 1, and a first rotating rod 4 is vertically provided in the housing 1 , the end of the output shaft of the motor 2 extends into the rotating cavity 3, and is fixedly connected with the upper end of the first rotating rod 4, and the lower end of the first rotating rod 4 is fixedly connected with an incomplete bevel gear 5;

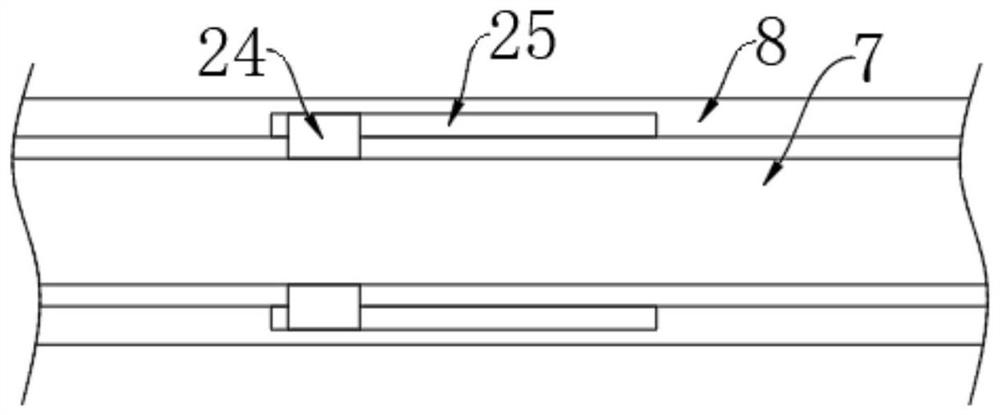

[0026] The trigger mechanism, the trigger mechanism includes the second rotating rod 7 horizontally arranged in the rotating chamber 3, the left end of the second rotating rod 7 is fixedly connected with the first bevel gear 6 matched with the incomplete bevel gear 5, when the incomplete bevel gear 5 meshes with the first bevel gear 6, the incomplete bevel gear 5 drives the first bevel gear 6 to rotate, and when the incomplete bevel gear 5 does not mesh with ...

Embodiment 2

[0034] refer to Figure 5 The difference between this embodiment and Embodiment 1 is that a slide plate 27 is horizontally provided in the rotating cavity 3, and the sliding plate 27 is slidably connected with the inner wall of the rotating cavity 3, and the sliding plate 27 is connected to the inner bottom of the rotating cavity 3 through two second springs. 28 is elastically connected, and the part of the second rotating rod 7 located in the rotating cavity 3 is fixedly connected with a cam 26 matched with the slide plate 27, and under the elastic action of the two second springs 28, the slide plate 27 is offset against the cam 26, that is, When the second rotating rod 7 rotates, it will drive the slide plate 27 to move up and down. The second rotating rod 7 is provided with a liquid outlet pipe 30. The left end of the liquid outlet pipe 30 communicates with the rotating chamber 3, and the sleeve 8 on the left side is set An annular hollow plate 31 is provided, the outer inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com