Automatic cleaning device and method for scale layer on inner wall of heat exchange tube of thermal equipment

A thermal equipment, automatic cleaning technology, applied in the direction of rotating equipment cleaning, cleaning heat transfer devices, lighting and heating equipment, etc., can solve the problems of increasing the risk of experimental personnel contacting dangerous chemicals, endangering physical health, and non-disclosure, etc. Achieve the effect of improving occupational health and safety level, reducing pollution and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

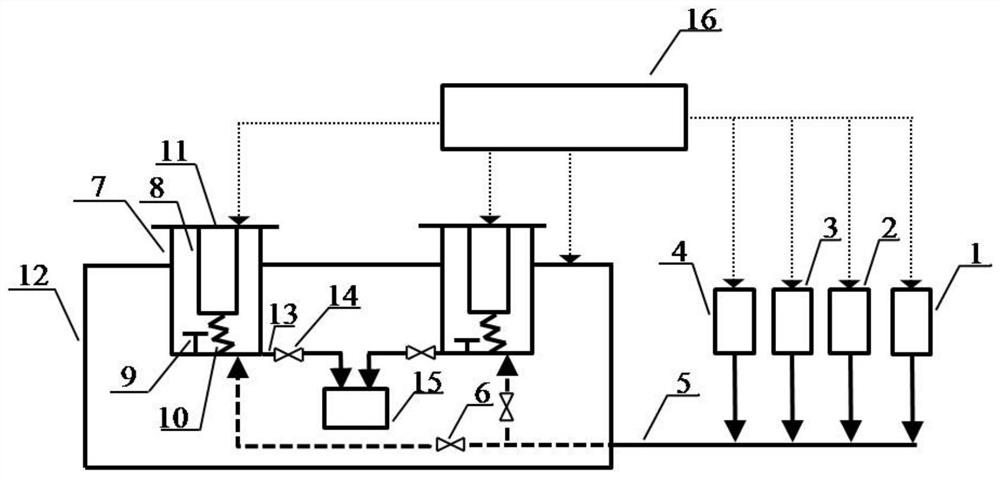

[0024]The present invention will be further described below in conjunction with the drawings.

[0025]Seefigure 1, An automatic cleaning device for the scale layer on the inner wall of the heat exchange tube of a thermal equipment, comprising a medicament configuration component and a constant temperature bath 12, in which at least one cleaning container 7 is provided, and the cleaning container 7 is provided with a brush for cleaning the tube, The bottom of the cleaning container 7 is provided with a waste liquid discharge pipe 13, and the waste liquid discharge pipe 13 is connected to the waste liquid collection tank 15. The pharmaceutical configuration component is connected to the cleaning container 7 through the cleaning solution input pipe 5, and the cleaning solution input pipe 5 is provided with a first The flow regulating valve 6, the waste liquid discharge pipe 13 is provided with a second flow regulating valve 14. The first flow regulating valve 6 and the second flow regulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com