Method and system for determining ductile-brittle transition temperature of Q460 power transmission tower material

A technology of ductile-brittle transition temperature and transmission tower, which is applied in the field of power transmission and transformation engineering, can solve the problems of large error in evaluation results, single consideration factors, and poor practicability, and achieve the effects of improving accuracy, simple principle, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

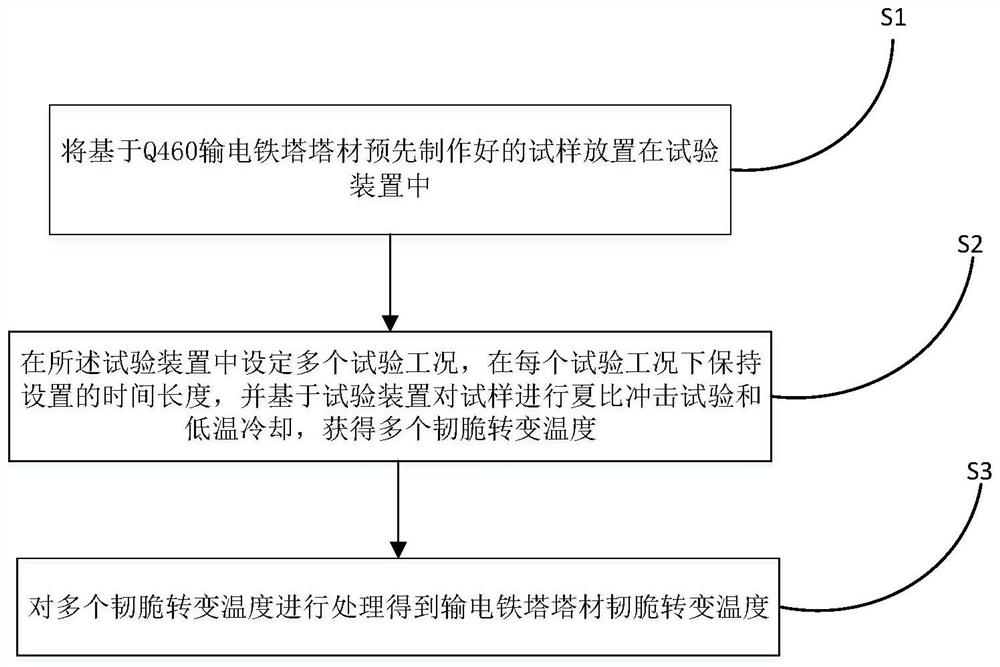

[0063] Such as figure 1 As shown, a method for determining the ductile-brittle transition temperature of a Q460 power transmission tower material provided by the invention includes:

[0064] Step S1, placing the prefabricated sample based on the Q460 transmission tower material in the test device;

[0065] Step S2, setting a plurality of test conditions in the test device, maintaining the set time length under each test condition, and performing a Charpy impact test and low-temperature cooling on the sample based on the test device to obtain multiple toughness Brittle transition temperature;

[0066] Step S3, processing multiple ductile-brittle transition temperatures to obtain the ductile-brittle transition temperature of the transmission tower material.

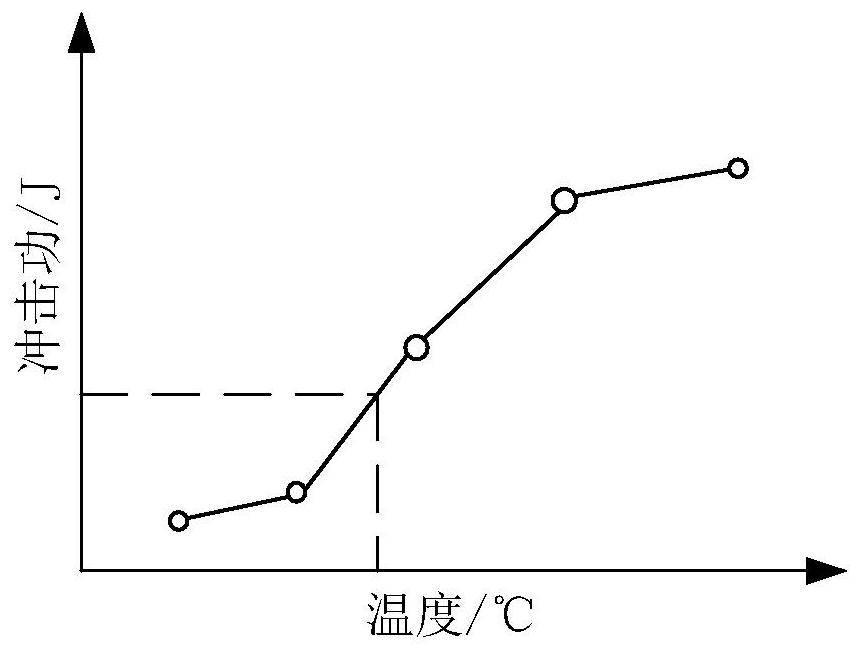

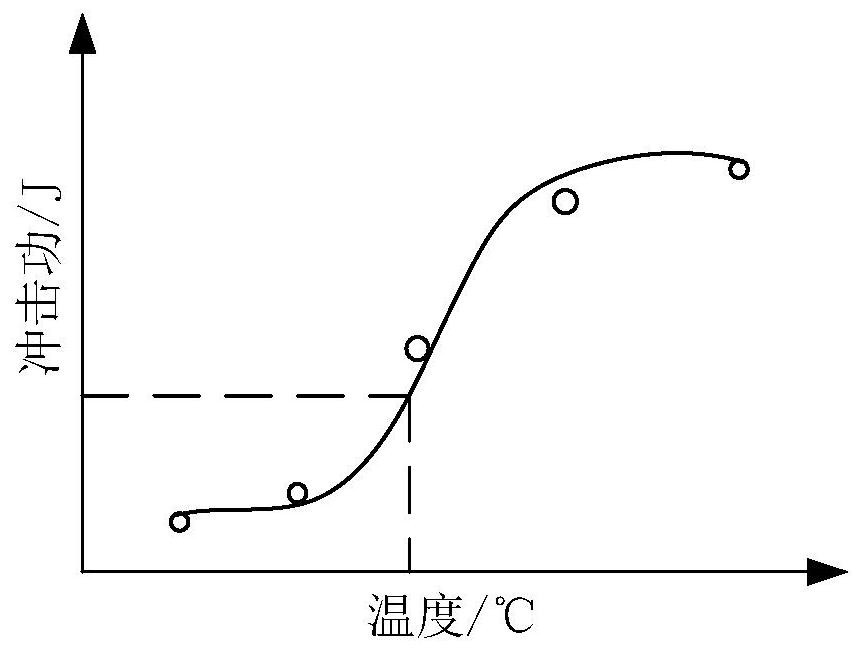

[0067] The technical solution provided by the invention includes a sample preparation method, a test temperature setting method, a heat preservation method, a test method, a data processing method, a method for determinin...

Embodiment 2

[0095] Based on the same inventive concept, an embodiment of the present invention also provides a system for determining the ductile-brittle transition temperature of a Q460 transmission tower material, including:

[0096] The preparation module is used to place the prefabricated samples based on the Q460 transmission tower material in the test device;

[0097] The test module is used to set multiple test conditions in the test device, maintain the set time length under each test condition, and perform Charpy impact tests and low-temperature cooling on the samples based on the test device to obtain multiple test conditions. a ductile-brittle transition temperature;

[0098] The processing module is used to process multiple ductile-brittle transition temperatures to obtain the ductile-brittle transition temperature of the transmission tower material.

[0099] In an embodiment, the test module includes:

[0100] The Charpy impact test unit is used to perform the Charpy impact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com