Large-view-field ultra-long lens cone monitoring lens for high-temperature combustion furnace

A high-temperature combustion and large field of view technology, applied in the optical field, can solve the problems of enlarged beam aberration and shortened optical structure, and achieve the effects of reducing volume, reducing production cost, and reducing aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

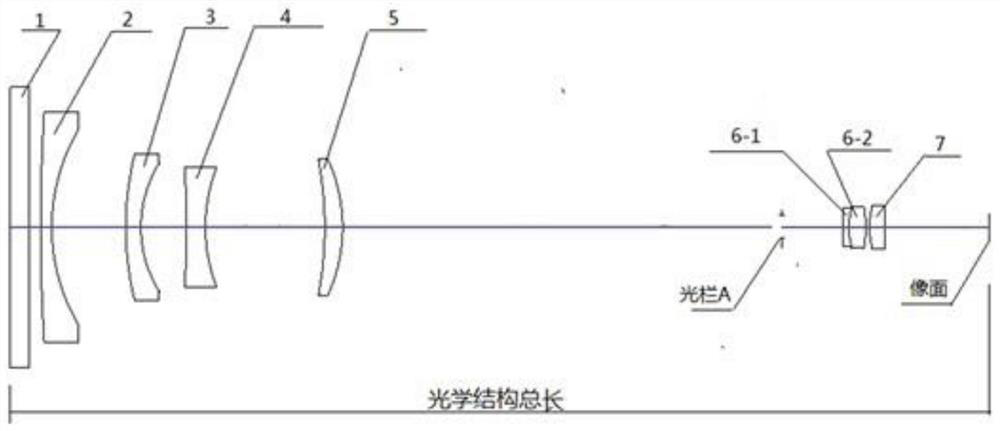

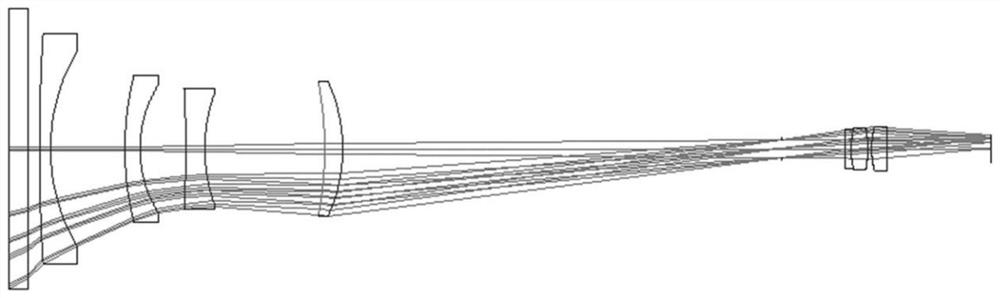

[0028] In the lens structure of Embodiment 1, the full field of view 2w≥90°, the focal length f'=5mm; the relative aperture D / f'=1 / 5, where D is the diameter of the entrance pupil; the object distance L=5000 mm, and the rear working distance is 27.4mm, the total length of the optical system is 258 mm. The image height of the full field of view can fully match the industrial imaging camera with a 2 / 3-inch CCD chip. The MTF value of the transfer function of each field of view at a frequency of 50 line pairs / mm can reach more than 0.7, and the resolution of the lens is excellent.

[0029] According to the market demand, the focal length of the lens is scaled proportionally. The range of optical performance parameters of the lens structure of this application: full field of view 2w≥90°, focal length f'=4mm~6mm; relative aperture D / f '=1 / 4.5~1 / 5.6, where D is the diameter of the entrance pupil; the object distance L=4500 mm to 5500 mm, the rear working distance is 26 mm to 28 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Focal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com