Sugarcane planter planting density speed-dependent synchronous control system

A synchronous control and planter technology, applied in general control systems, control/regulation systems, and simultaneous control of multiple variables, etc., can solve problems such as low planting density, high planting density, and tractor walking speeds that cannot be synchronized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

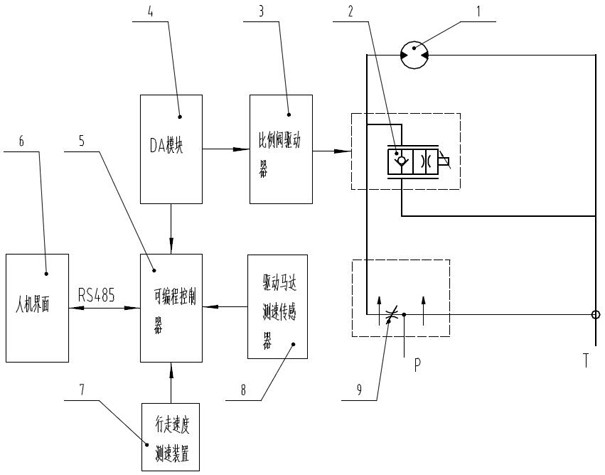

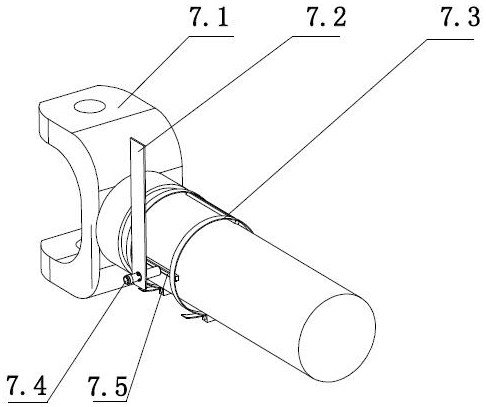

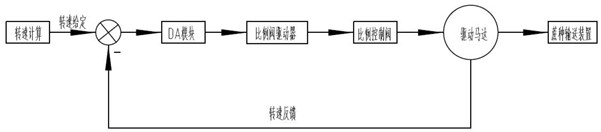

[0014] Such as figure 1 As shown, the sugarcane planter planting density synchronous control system with speed includes a hydraulic drive system and an electrical control system, wherein the hydraulic drive system includes a proportional control valve 2 and a drive motor 1, P is the hydraulic oil inlet, T is the hydraulic oil return port, The drive motor 1 is used to drive the sugarcane seed conveying device of the sugarcane planter, and the proportional control valve 2 is connected to the bypass of the drive motor 1, and the proportional control valve 2 is an electronically controlled proportional control valve; wherein the electric control system includes a proportional valve driver 3, DA module 4, programmable controller 5, walking speed speed measuring device 7, drive motor speed measuring sensor 8, man-machine interface 9, proportional valve driver 3 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com