Inspection method and system and inspection management platform

A management platform and inspector technology, applied in image data processing, inspection time patrol, electrical digital data processing, etc., can solve the problem of inability to conduct on-site safety monitoring at the job site, inability to achieve continuous operation without gaps, and no real-time electronic data. and other problems, to achieve the effect of improving real-time acquisition and storage capabilities, realizing dynamic interaction, improving practical operation and the depth of mastery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

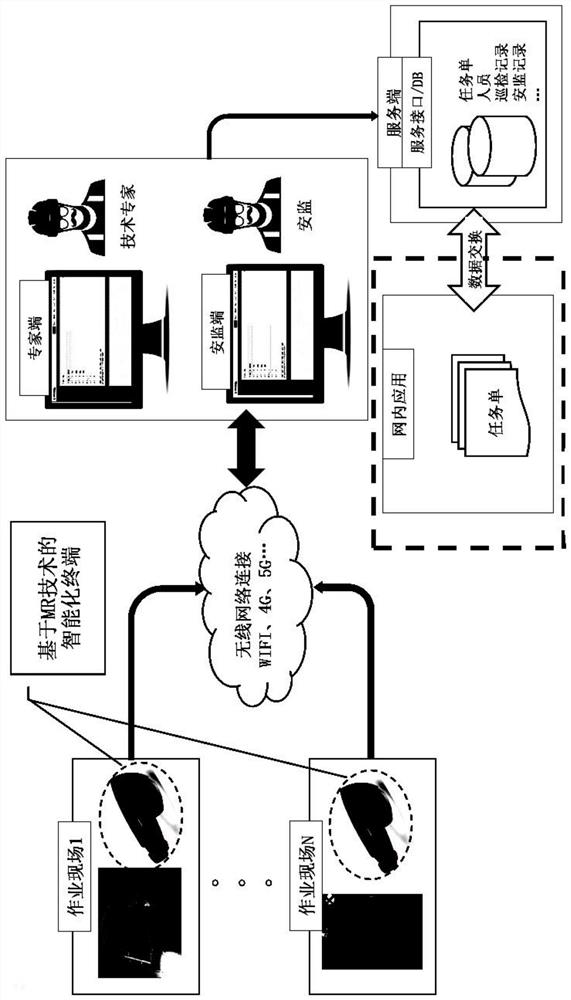

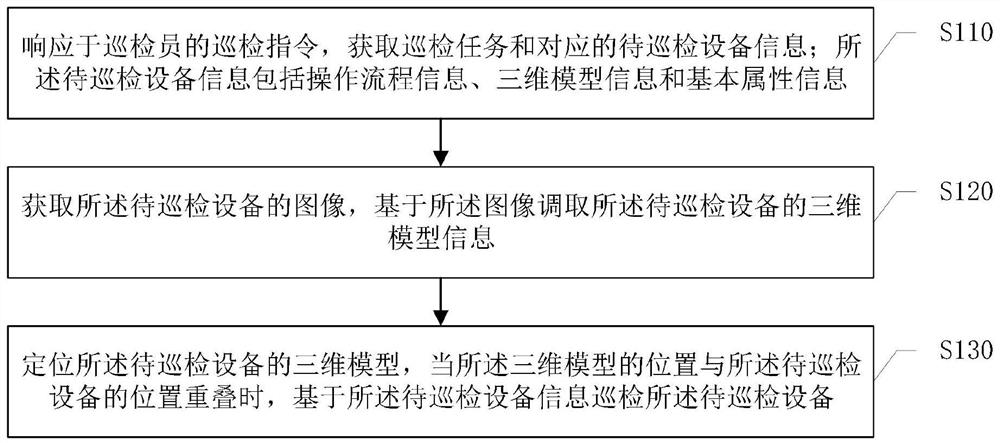

[0062] Embodiment one, such as figure 1 As shown, the present invention provides a kind of inspection method, comprises steps:

[0063] S110 In response to an inspection instruction from an inspector, acquire an inspection task and corresponding information on equipment to be inspected; the information on equipment to be inspected includes operation process information, three-dimensional model information, and basic attribute information.

[0064] Specifically, the inspector logs into the inspection interface through the inspection terminal, selects the inspection task and the corresponding inspection terminal information through gestures and head rotations, and the inspection terminal has the function of recognizing gestures and head rotations. The operation process information includes an operation process for correctly dismantling the equipment to be inspected, and the three-dimensional model information includes a constructed Revit model. The three-dimensional model refer...

Embodiment 2

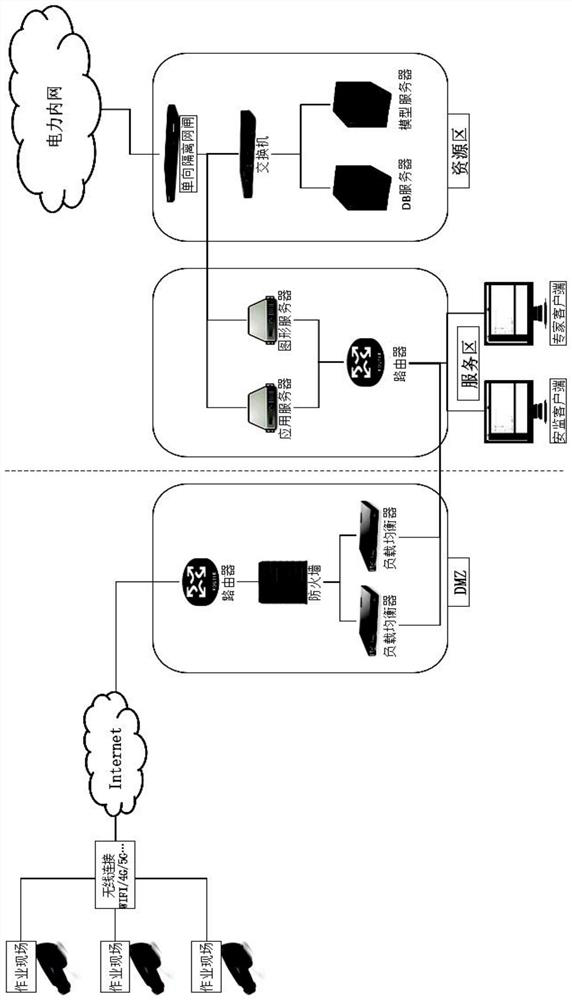

[0073] Embodiment two, such as figure 2 As shown, the present invention provides a kind of inspection method, comprises steps:

[0074] S210 Based on the inspection preparation information sequentially uploaded by the inspector, determine that the inspector has completed the inspection preparation, and issue inspection tasks and equipment information to be inspected. The inspection tasks include main transformer inspection and switch centering , inspection records, installation and testing; the three-dimensional model information includes a Revit model.

[0075] S220 Import the created Revit model into Unity for compilation to realize viewing of the 3D model; the viewing methods include moving, rotating, and zooming.

[0076] Specifically, for a 3D object in a project, the 3D model can be moved, rotated, scaled, etc. in the inspection terminal. Most engineering projects will create a Revit model in advance, which can be imported into Unity and compiled to the inspection ter...

Embodiment 3

[0101] Embodiment three, such as image 3 As shown, the present invention also provides an inspection system, including at least one inspection terminal, an inspection management platform, and a server.

[0102] Specifically, the technical basis of the inspection terminal is virtual visualization technology. Virtual visualization technology is a theory, method and technology that uses computer graphics and image processing technology to convert data into graphics or images for display, and then perform interactive processing.

[0103] For example: VR (virtual reality technology), VR (Virtual Reality, namely virtual reality, referred to as VR), its specific connotation is: comprehensive utilization of computer graphics system and various interface devices such as reality and control, generated on the computer, interactive Technology that provides immersion in a 3D environment. VR (Virtual Reality) technology can be widely used in many fields such as urban planning, interior d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com