An aerospace extravehicular power divider

A power divider and aerospace technology, applied in waveguide-type devices, circuits, connecting devices, etc., can solve the problems of inability to apply the temperature environment outside the spacecraft, the power divider cannot be applied, and the irradiation environment cannot be used for a long time. Simple and easy to produce, expand the application field and scope, good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

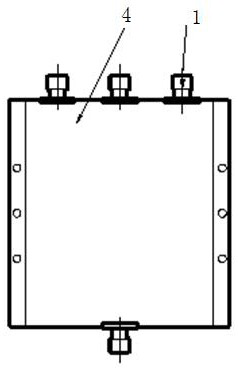

[0040] In the present embodiment, the shell is 4 mm, the second upper shielding plate 62 and the second lower shielding plate 64 are 0.4 mm in thickness, and the thickness of the first upper shielding plate 61 and the first lower shielding plate 63 is 0.5 mm. mm, the anti-irradiation ability is: anti-irradiation radiation dose: 30Mrad (Si) / metering rate: 2 ~ 50rad / Si / s conditions; the dose of proton irradiation is not less than 10 3 Gy~10 5 Irradiated total dose of Gy; screw fixation dense 2.6×10 -3 piece / mm 2 . After -179°C liquid nitrogen to +100°C / 100 temperature shocks and -100°C to +100°C / 25.5 thermal vacuum tests, it meets the long-term use requirements of -95°C to +95°C.

Embodiment 2

[0042] The shell is 4mm, the thickness of the lead plate is 0.4mm, the thickness of the stainless steel plate is 0.5mm, and the anti-radiation ability is: anti-irradiation radiation dose: 30Mrad (Si) / metering rate: 2 ~ 50rad / Si / s conditions; withstand proton irradiation Dose not less than 10 3 Gy~10 5 Irradiated total dose of Gy; screw fixation dense 9.5×10 -3 piece / mm 2 . After -179°C liquid nitrogen ~ +100°C / 100 temperature shocks, -145°C ~ +125°C / 12.5 thermal vacuum tests and adapting to the limit temperature of -145°C ~ +125°C outside the space cabin and the total radiation dose of 30Mrad (Si ) level test, meeting the long-term use requirements of -145°C ~ +125°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com