Outsourcing stainless steel tube cable and manufacturing method thereof

A technology of stainless steel and steel pipes, applied to building components, walls, buildings, etc., can solve the problems that steel strand cables are not suitable for use in cable net curtain walls, and achieve the effects of simple structure, improved construction efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

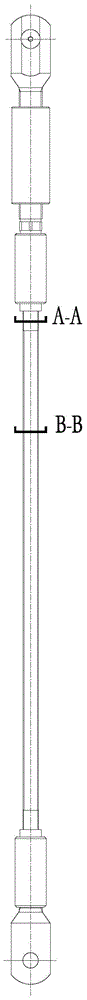

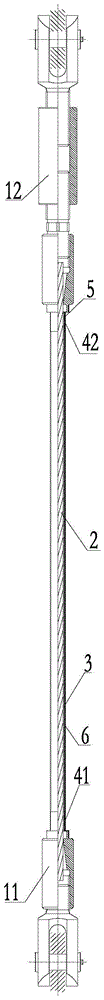

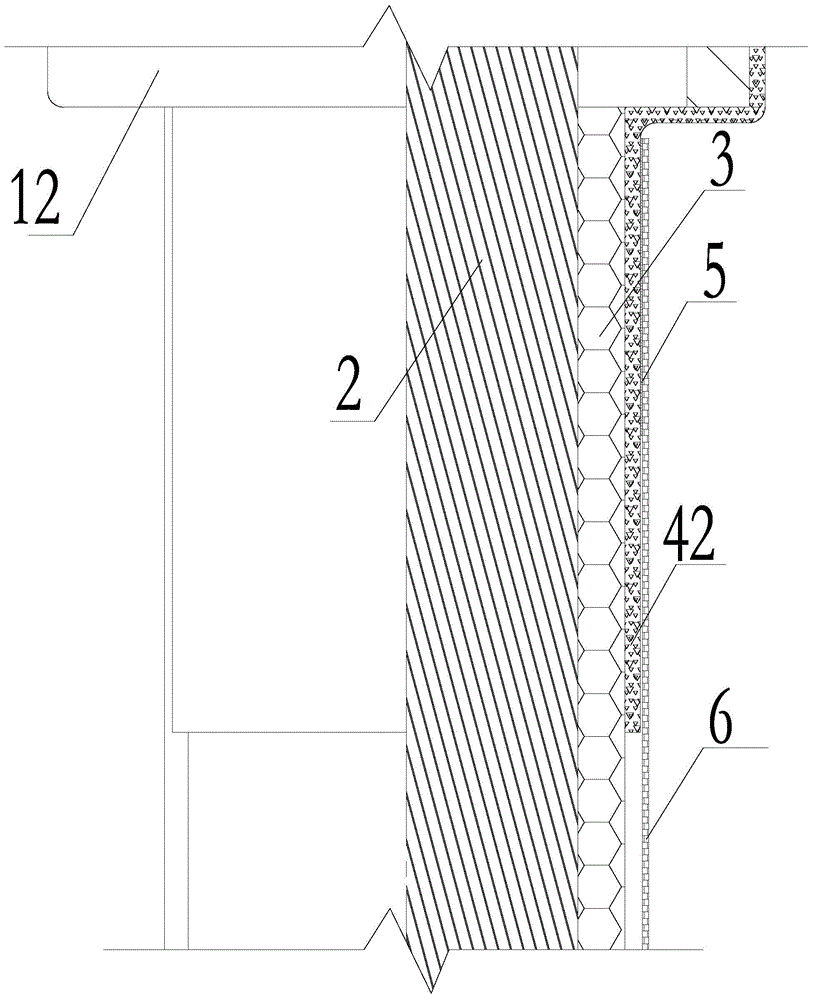

[0024] Such as figure 1 , figure 2 , image 3 , Figure 6 As shown, the outsourcing stainless steel pipe cable includes: the first steel strand connection assembly 11, the second steel strand connection assembly 12, a single steel strand 2, polyethylene coating 3, the first thermoplastic pipe 41, the second Two thermoplastic pipes 42 and stainless steel pipes 6; wherein: the first steel strand connection assembly 11 and the second steel strand connection assembly 12 are respectively connected to the two ends of a single steel strand 2, and the connection method can be clip type or Squeeze type; the first steel strand connection component 11 has a fork lug anchor head at one end and a sleeve at the other end. Single or double hinged ears are used; the second steel strand connection assembly 12 is an adjustable fork ear anchor head, one end is a fork ear anchor head, the other end is a sleeve, and the middle is an adjustable member. The anchor head of the fork lug adopts si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com