Stator for an electric machine with improved cooling, electric machine and motor vehicle

A technology for motor vehicles and stators, used in cooling/ventilation devices, electromechanical devices, electric components, etc., can solve the problems of no magnetic permeability, hindering stator magnetic flux, high power loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

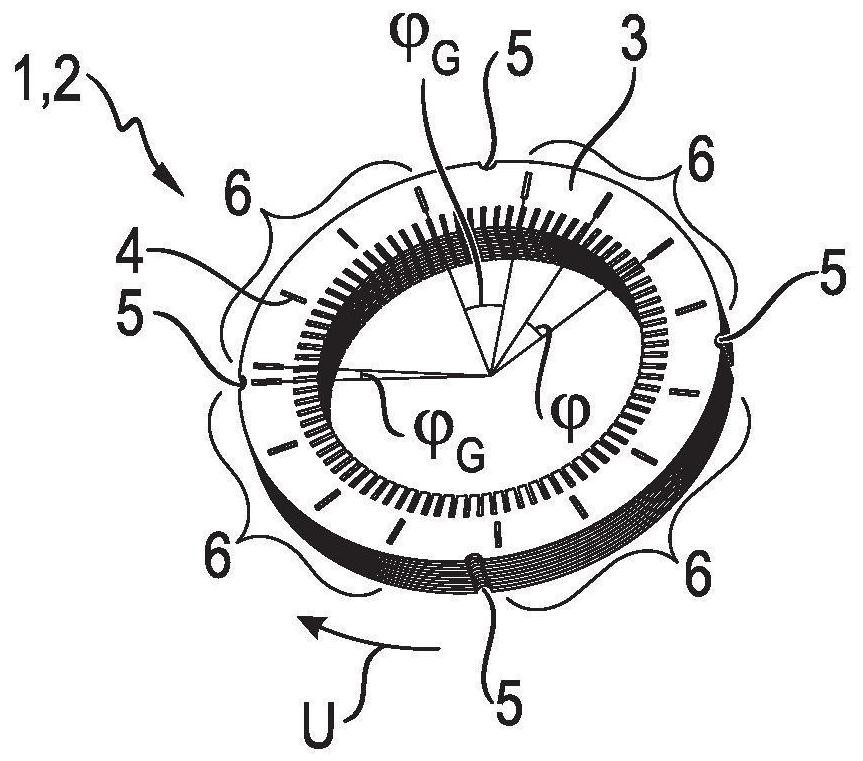

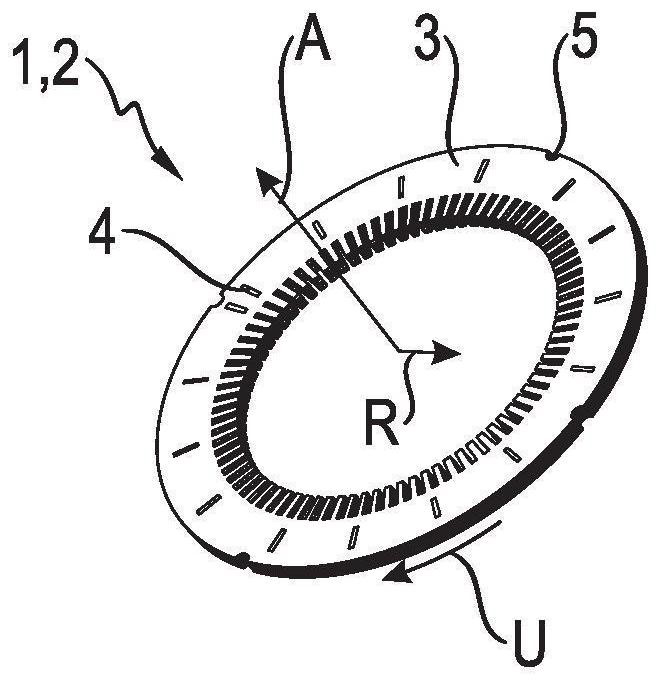

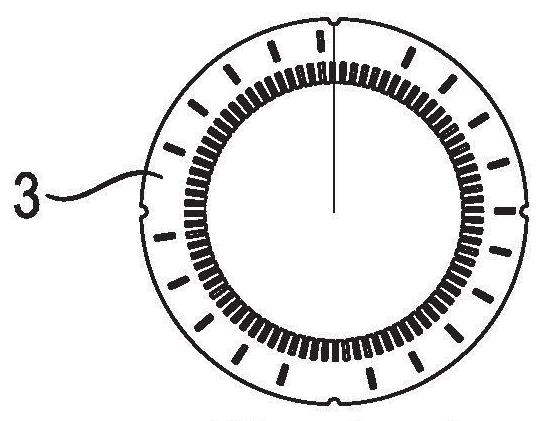

[0028] FIG. 1( a ) and FIG. 1( b ) respectively schematically show a stator 1 with a stator lamination pack 2 according to an exemplary embodiment of the present invention. The stator lamination pack 2 has stator laminations 3 stacked on top of each other in the axial direction A and welded to each other. When the stator 1 is in operation, heat is mainly generated inside the stator 2 . At the outer side of the stator 1 , a cooling jacket made of aluminum, not shown, is shrunk. A cooling liquid flows through the cooling jacket and cools the outer side of the stator lamination stack 2 . The cooling cover is fixed at four aligned recesses 5 that are evenly distributed in the azimuthal direction. In order to improve the heat conduction from the inside of the stator lamination stack 2 towards the outside of the stator lamination stack 2 , the stator laminations 3 have strip-shaped inserts 4 arranged in the radial direction R. These inserts 4 are made of a material with good ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com