Food processor

A technology for food cooking machines and machine bases, which can be used in home appliances, applications, kitchen utensils, etc. It can solve the problems of poor alignment of the motor shaft and the knife shaft, and high noise, so as to improve the user experience, reduce noise, and reduce noise. The effect of fit clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

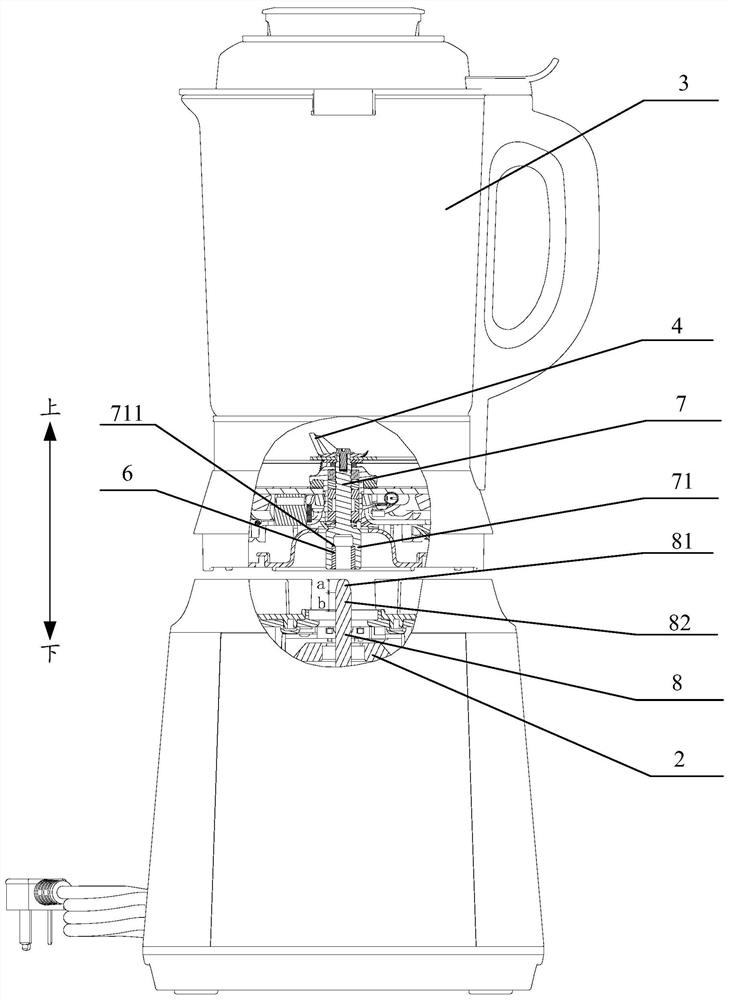

[0081] The clutch part is a one-way bearing 6.

[0082] The one-way bearing 6 (or needle roller clutch, overrunning clutch) is a kind of bearing that can rotate freely in one direction and is locked in the other direction. Therefore, the one-way bearing 6 is installed on the connecting shaft 7, and the The cooperating shaft 8 is inserted into the one-way bearing 6. When the one-way bearing 6 is locked, the cooperating shaft 8 can rotate synchronously with the connecting shaft 7 to realize the driving of the drive shaft 21 to the knife shaft 5. When the one-way bearing 6 can rotate freely At this time, the matching shaft 8 can be disengaged from the one-way bearing 6, and then the separation of the machine base 1 and the stirring cup 3 can be realized. Therefore, using the one-way bearing 6 as the clutch part can directly adopt standard parts for assembly, which is easy to obtain materials and has high stability, which is beneficial to market promotion of the product. In addit...

Embodiment 2

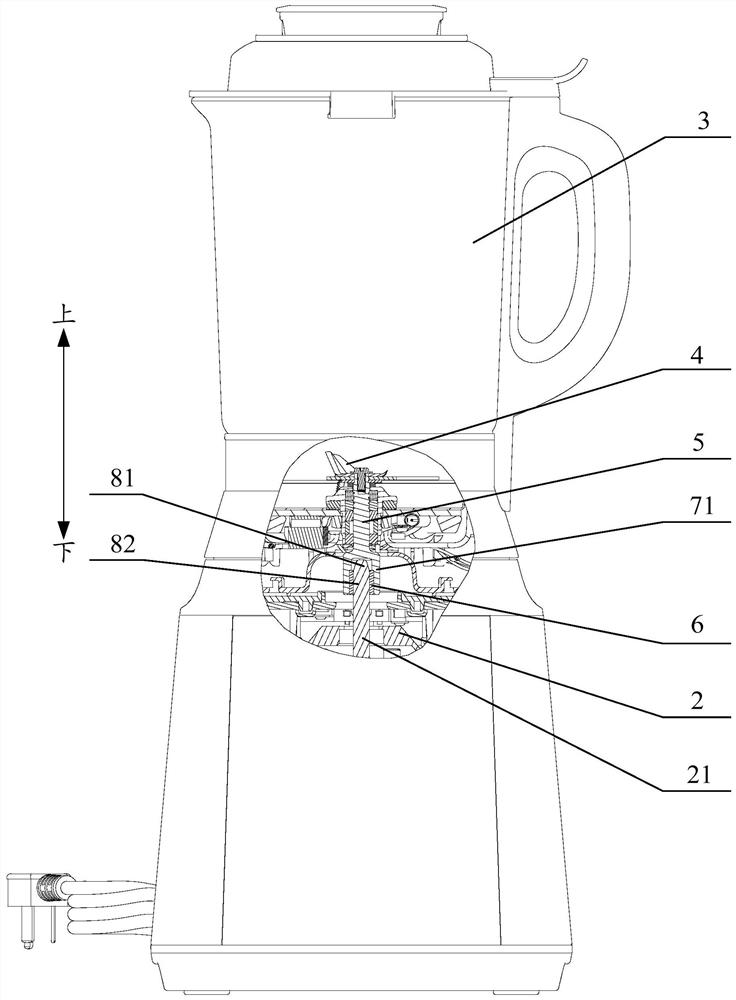

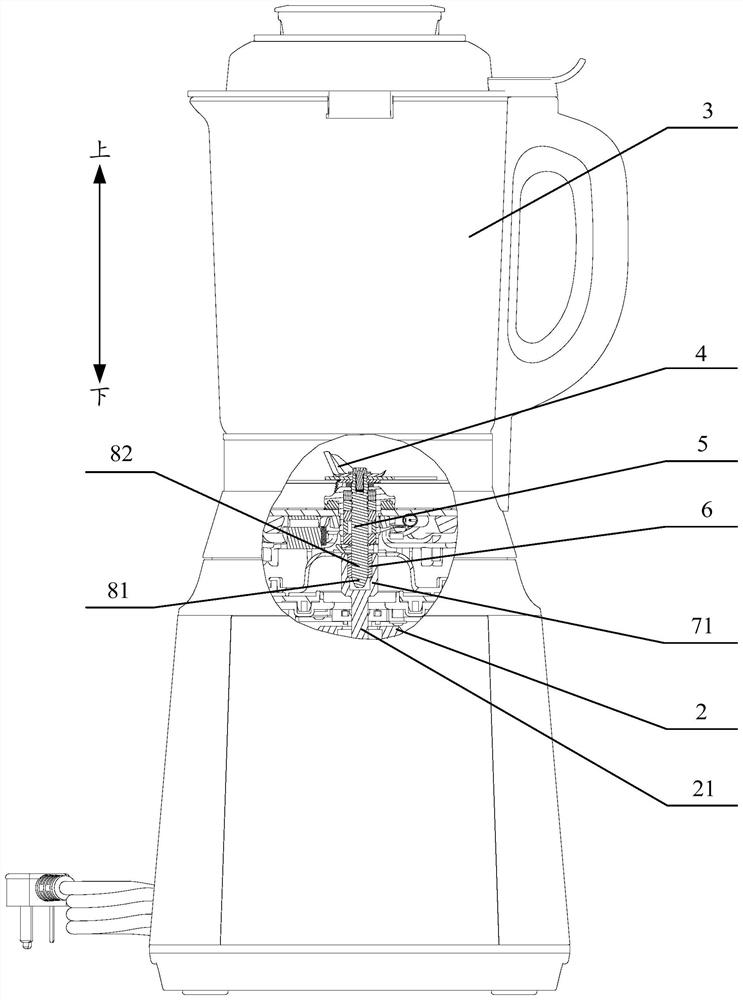

[0103] The difference from Embodiment 1 is that the drive shaft 21 is configured as the connecting shaft 7, and the cutter shaft 5 is configured as the mating shaft 8, such as image 3 and Figure 4 shown.

[0104] The principle is basically the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0106] The clutch part includes a fixed sleeve, which is fixedly connected with the connecting shaft 7, the cross section of the inner space of the fixed sleeve is non-circular, and the end of the mating shaft 8 close to the connecting shaft 7 is formed to match the shape of the fixed sleeve The connecting section is suitable for inserting or separating from the fixing sleeve.

[0107] The clutch part includes a fixed sleeve, which is fixedly connected with the connecting shaft 7, realizing the assembly and cooperation of the clutch part and the connecting shaft 7; the section of the fixed sleeve is non-circular (such as D-shaped, triangular, X-shaped, etc.), It can be inserted and matched with the non-circular connecting section on the matching shaft 8 to drive the matching shaft 8 to rotate synchronously. When the connecting section comes out of the fixed sleeve, the normal separation of the machine base 1 and the stirring cup 3 can be realized. The structure and principle ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com