Cone Crusher Fault Prediction Method

A technology of cone crushers and crushers, applied in grain processing, etc., which can solve problems such as weak anti-interference ability, affected production, and enterprise losses, and achieves reduced false alarm probability and missed detection rate, reliable fault diagnosis results, and increased The effect of anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

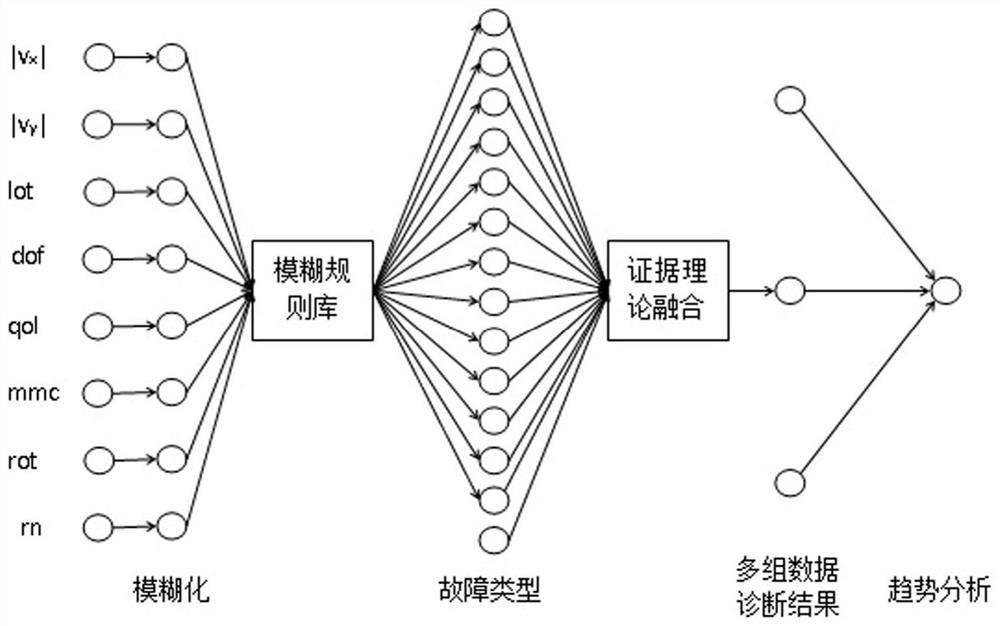

[0033] like figure 1 , 2 As shown, the cone crusher failure prediction method of the present invention is characterized in that it comprises the following steps:

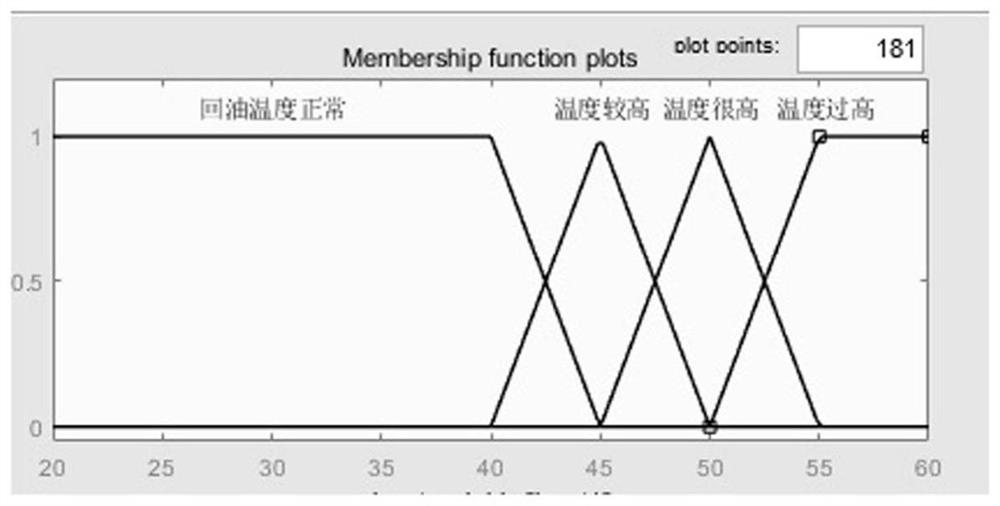

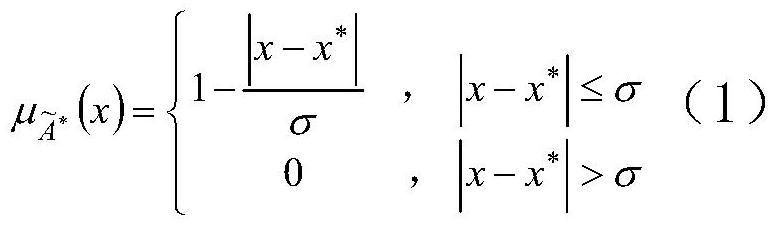

[0034] (1) According to the various fault thresholds and real-time requirements of the crusher, the variable horizontal vibration |v x |, vertical vibration |v y |, lubricating oil temperature lot, lubricating oil flow qol, main motor current mmc, running noise rn, select the trapezoidal membership function; for the variable oil filter pressure difference dof, return oil temperature rot, select the trapezoidal membership function and triangular membership function binding;

[0035] (2) Establish a fuzzy rule base based on the crusher data that can be collected on site;

[0036] (3) Carry out fuzzy reasoning according to the Madani algorithm to obtain the fault membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com