Water gate steel wire rope rust removal maintenance device

A technology for steel wire ropes and sluice gates is applied in the field of rust removal and maintenance devices for sluice wire ropes, which can solve the problems of time-consuming and labor-intensive, inconvenient installation, disassembly and installation, and achieve the effects of improving work efficiency, saving maintenance time, and facilitating cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

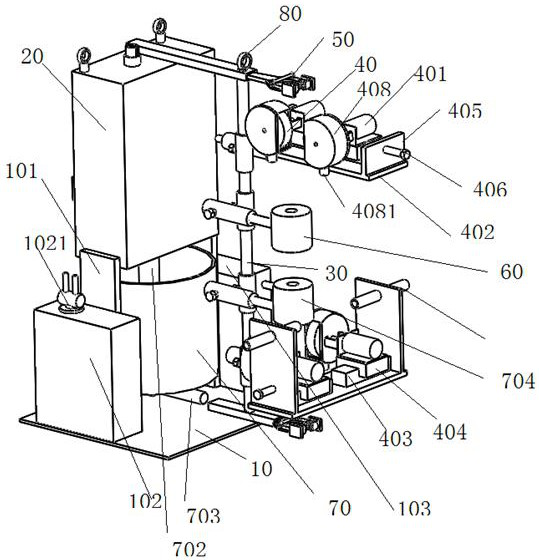

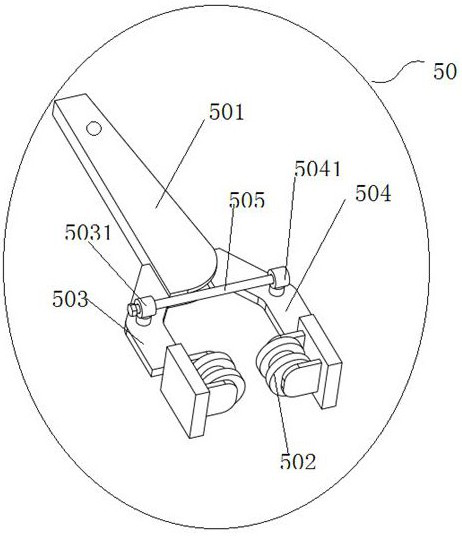

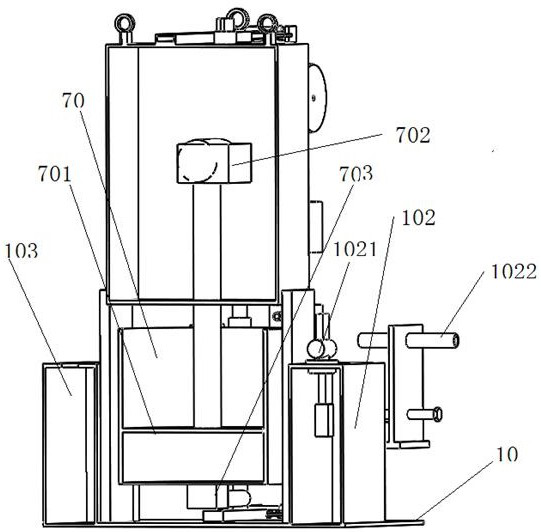

[0018] Such as figure 1 , figure 2 , image 3 As shown, a sluice steel wire rope derusting and maintenance device includes a base plate 10, two vertically parallel vertical plates 101 are fixedly connected to the base plate 10, and a control box 20 is fixedly connected to the upper end of the vertical plate 101; Pole 30, the bottom end of the pole 30 is fixedly connected to the base plate 10, and the top end is fixedly connected to the top of the control box 20; rust removal device, the rust removal device is fixedly connected to the pole 30, and the rust removal device includes Four steel wire brush rollers 40, the steel wire brush rollers 40 are divided into two groups, each group of steel wire brush rollers 40 is arranged symmetrically around the steel wire rope to be maintained, and the centers of the steel wire brush rollers 40 are respectively fixedly connected to the output shaft of the driving motor 401, The drive motor 401 is electrically connected to the control b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com