Industrial robot calibration method considering parameter coupling

A technology of industrial robot and calibration method, which is applied in the field of industrial robot calibration, can solve the problems of not considering, not considering the coupling relationship of geometric parameters, and unsuitable robot calibration, etc., and achieves the effect of convenient compensation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A method for calibrating an industrial robot considering parameter coupling of the present invention will be described in detail below in conjunction with the embodiments and drawings.

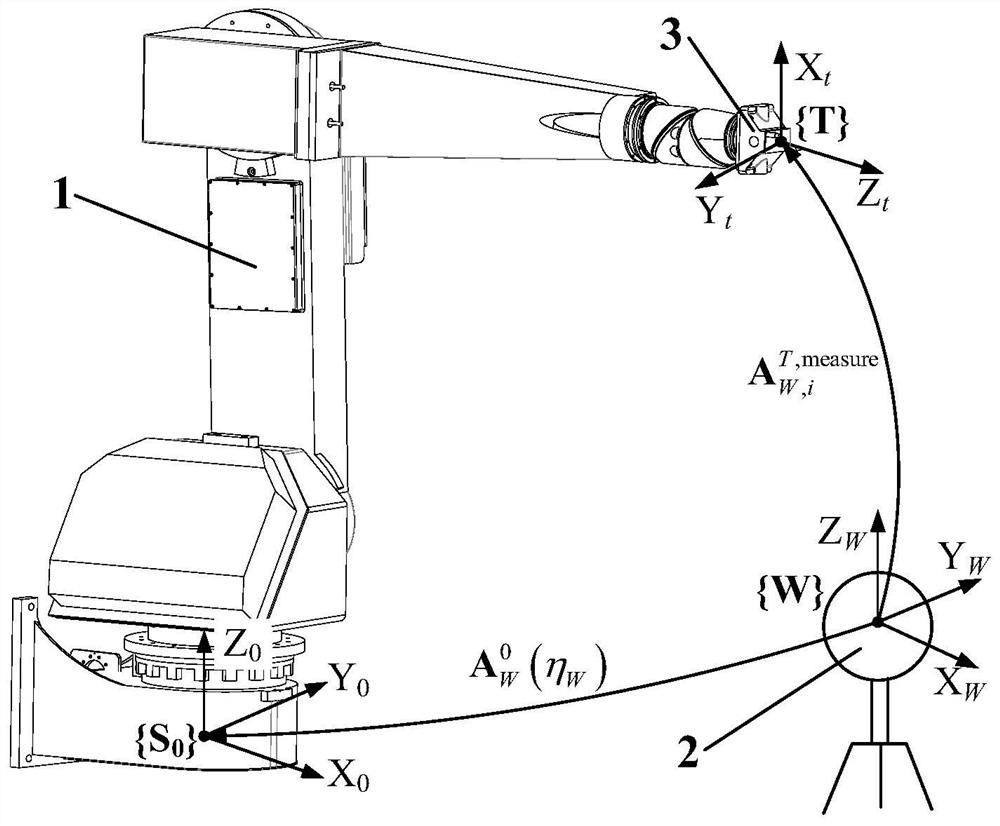

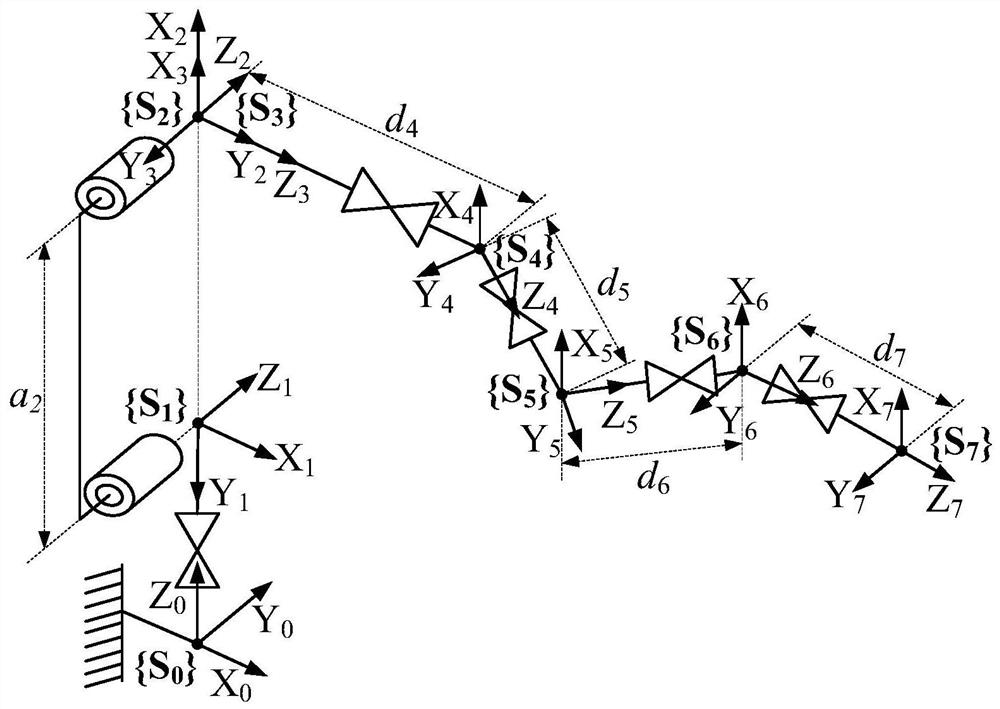

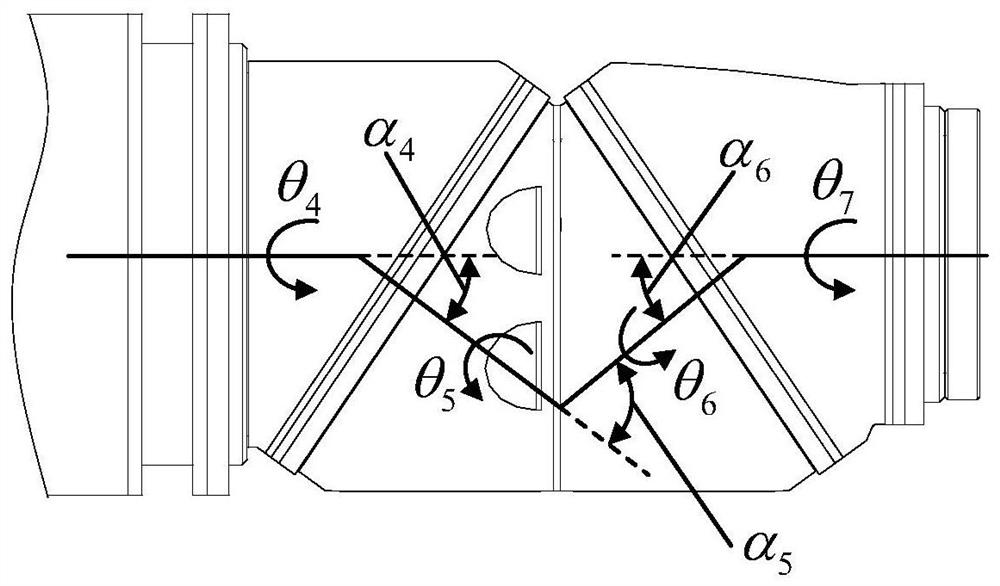

[0039] Such as figure 1 , figure 2 , image 3 As shown, a kind of industrial robot calibration method considering parameter coupling of the present invention comprises the following steps:

[0040] 1) Provide an industrial robot 1 with parameter coupling, a measuring device 2 independent of the industrial robot and a terminal calibration tool 3;

[0041] The industrial robot 1 has six degrees of freedom of motion and is composed of 7 sequentially connected rotary joints. In order to avoid redundancy, the rotation angle θ of the fifth rotary joint of the industrial robot is 5 and the rotation angle θ of the 6th revolving joint 6 Motion constraints are set between: θ 6 =-θ 5 , introduce a coupling relationship between the kinematic parameters of the industrial robot according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com