Material taking device, material yard applying material taking device and material stacking and taking method

A material reclaiming device and material technology, which is applied in the stacking, transportation and packaging of objects, building construction, etc., can solve the problems of limited blanking center distance, achieve reasonable mechanical performance, easy maintenance, and reduce civil engineering. The effect of the amount of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

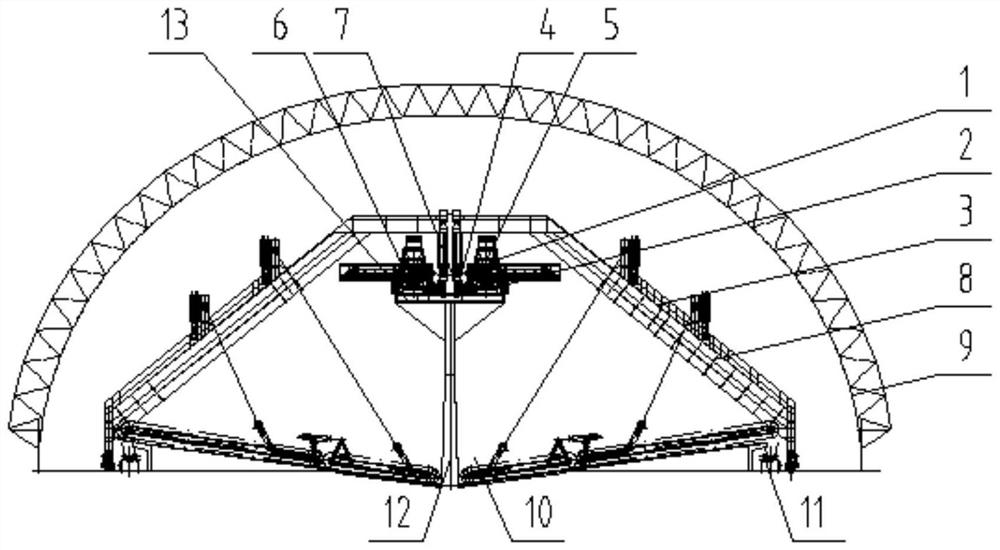

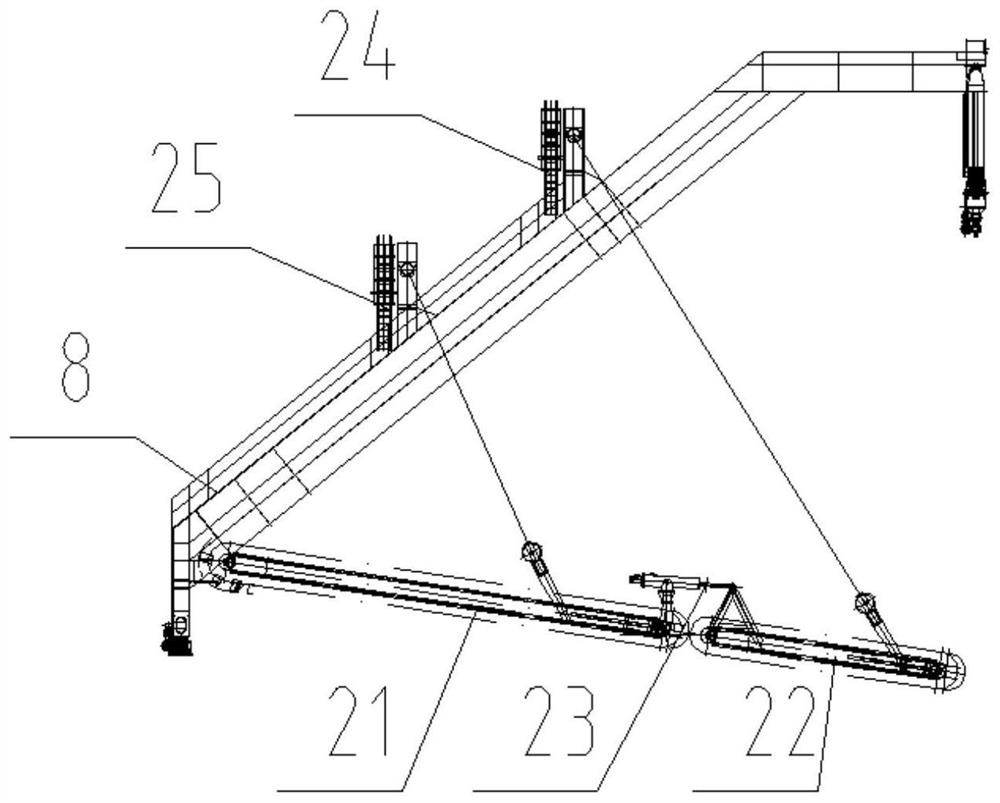

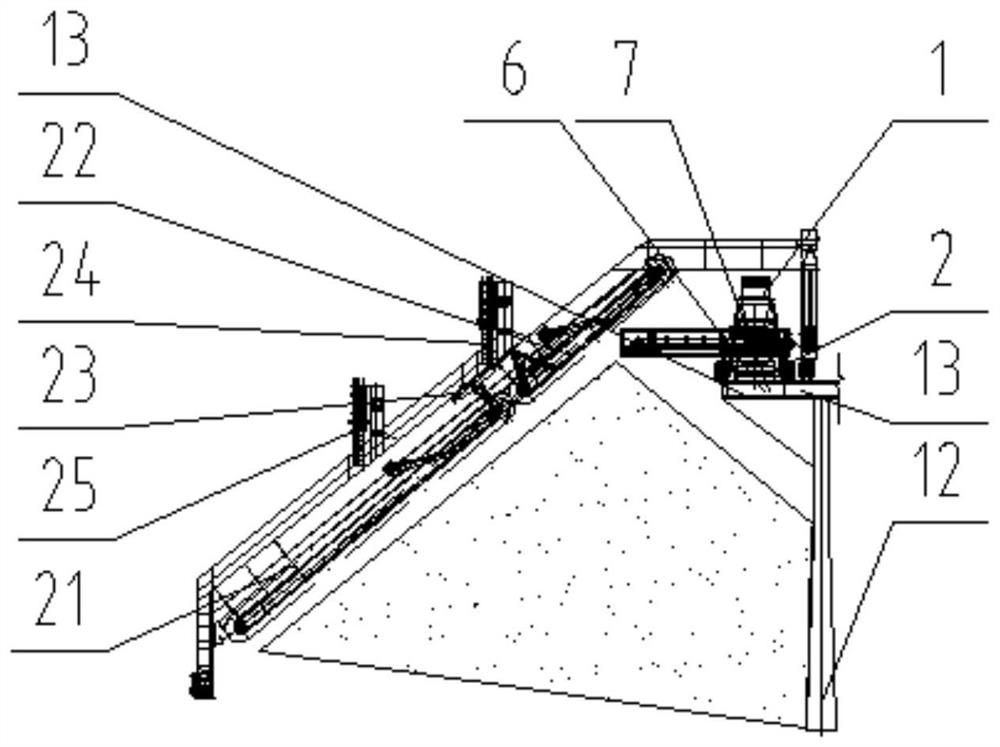

[0048] A new C-type environmental protection material yard, including a stacking device 1, a material reclaiming device 3, a stocking device running track 5, a material retrieving device running track, a material input conveyor 2, a material output conveyor 11, a storage yard 10 and Enclose material storage shed 9, be provided with vertical retaining wall 12 longitudinally along material storehouse 10 in the middle part of stock yard 10, the top of longitudinal retaining wall 12 is provided with top platform 13, and longitudinal retaining wall 12 is supported on the middle part of top platform 13 with A stable T-shaped structure is formed, and the left and right sides of the top platform 13 are provided with material input conveyors 2 and stacking devices 1 .

[0049] The stacking device 1 is arranged on the stocking device running track 5 on the top platform 13, the upper running track 4 of the reclaiming device is located between the two stocking device running tracks 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com