Flocculating agent feeding device for sewage treatment

A sewage treatment and feeding device technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of affecting the mixing effect of sewage and flocculant, blockage of water jets, etc. problem, to achieve the effect of improving flocculation effect, increasing stirring effect and improving practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

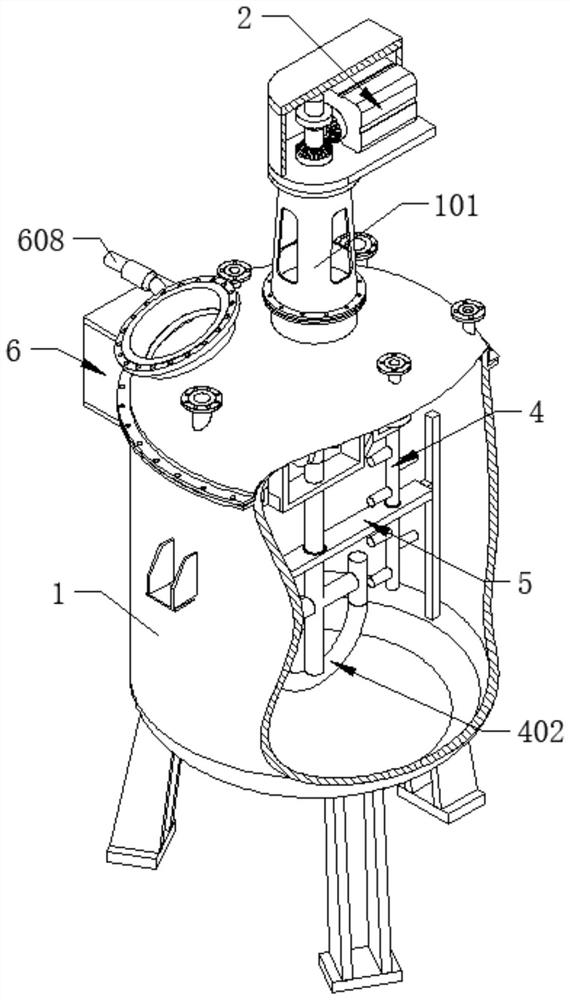

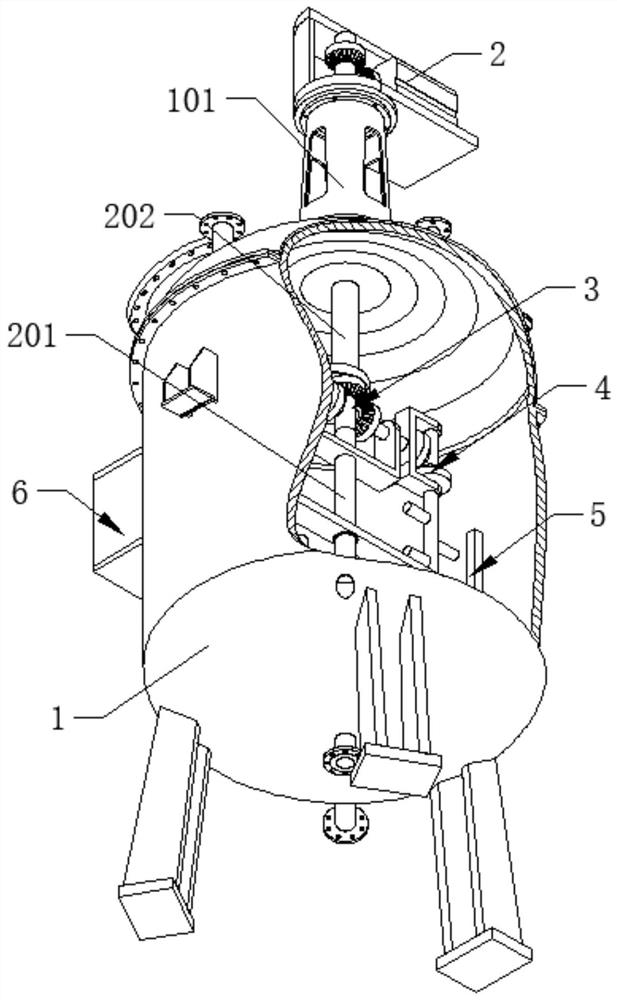

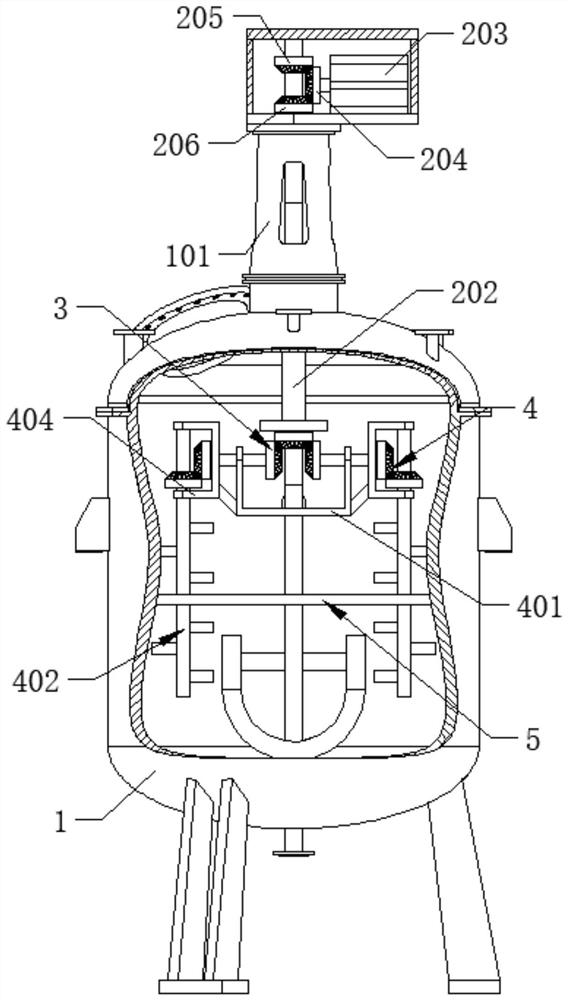

[0039] refer to Figure 3-7 , a flocculant feeding device for sewage treatment, which is basically the same as Example 1, and further, a flocculant feeding device for sewage treatment, including a tank body 1 and an intermittent feeding mechanism 6, and the intermittent feeding mechanism 6 is connected to the tank On the outer wall of the body 1, it is characterized in that the top wall of the tank body 1 is connected with a drive assembly 2, and the output ends of the drive assembly 2 are respectively connected with a first rotating shaft 201 and a second rotating shaft 202, and the first rotating shaft 201 and the second rotating shaft The shafts 202 are connected in rotation. The output ends of the first rotating shaft 201 and the second rotating shaft 202 are away from the drive assembly 2 and both pass through the tank body 1 and extend downwards. The outer walls of the first rotating shaft 201 and the second rotating shaft 202 are A first transmission assembly 3 that coo...

Embodiment 3

[0047] refer to Figure 1-7 , a flocculant feeding device for sewage treatment, which is basically the same as that of Embodiment 1, furthermore, the cleaning assembly 5 includes a connecting plate 501, and the connecting plate 501 is connected to the outer wall of the stirring assembly 402 through bearing rotation, and the two ends of the connecting plate 501 The wall is connected with a scraper 502 through a connecting block, and the scraper 502 matches the inner wall of the tank body 1; through the provided connecting plate 501, when the stirring assembly 402 rotates along the central axis of the first rotating shaft 201 and the second rotating shaft 202 , it will drive the connecting plate 501 to rotate along the central axis of the first rotating shaft 201 and the second rotating shaft 202, thereby driving the scrapers 502 connected to both ends of the connecting plate 501 to rotate along the first rotating shaft 201 and the second rotating shaft The central axis of 202 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com