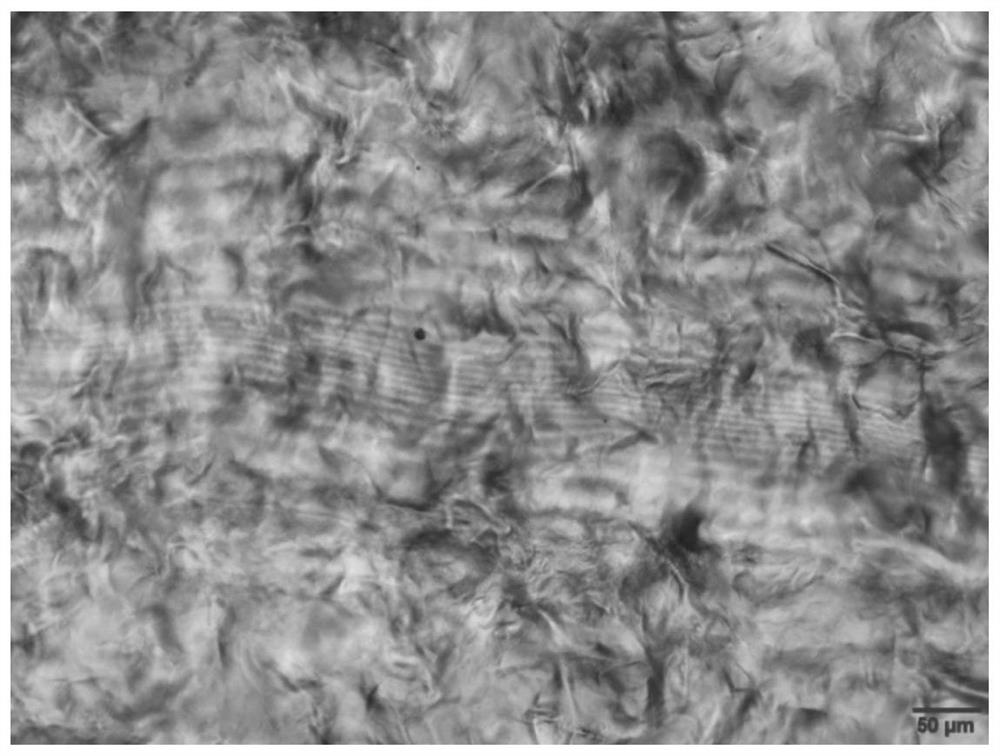

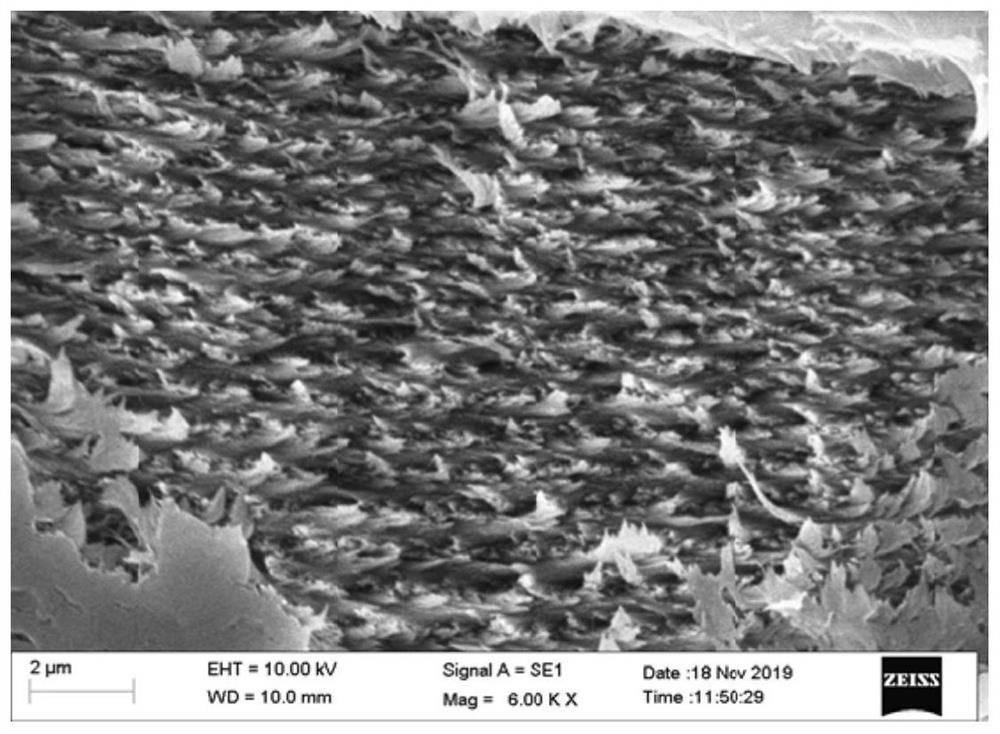

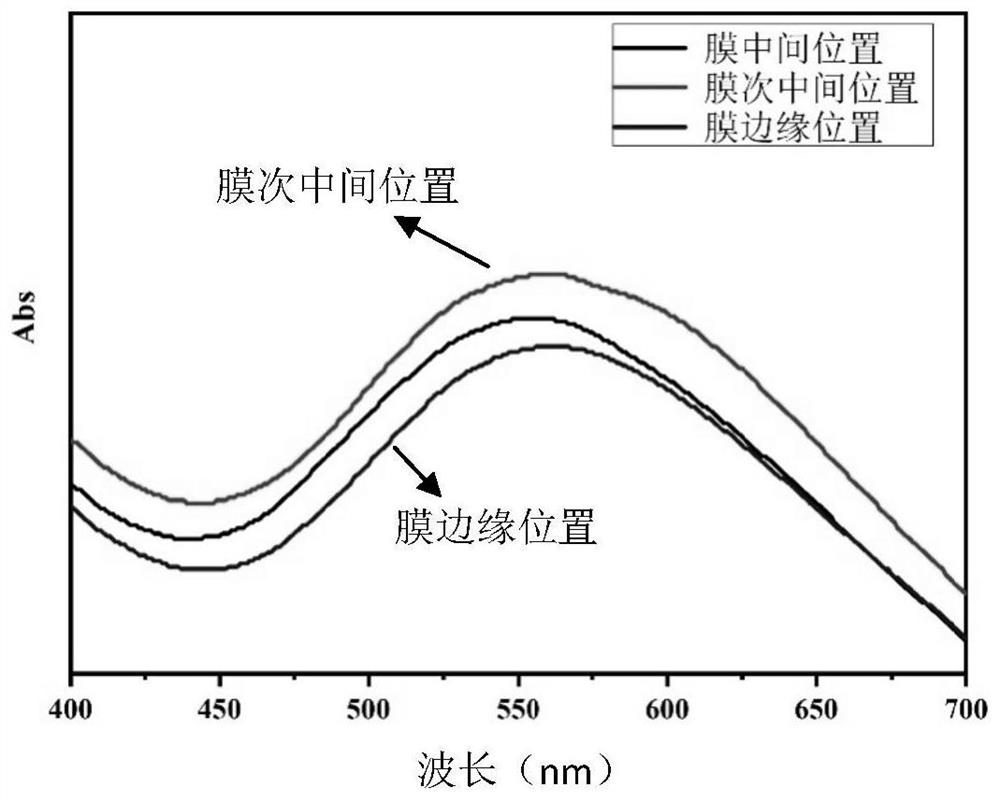

Panchromatic display film based on structural color and preparation method thereof

A full-color display and structural color technology, which is applied in the field of structural color-based full-color display film and its preparation, can solve the problems of film color coffee ring, many influencing factors, and uneven film color, and achieve bright structural color and process Controllable, wide-sourced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method for a flexible cellulose liquid crystal film, comprising the steps of:

[0038] (1) Mix 100g of microcrystalline cellulose with 80ml of concentrated sulfuric acid solution (concentration is 64wt%), under the condition of stirring (stirring speed is 300rpm), treat at 45°C for 60min, add 1000ml of deionized water, mix well and let stand 12h;

[0039] (2) Centrifuge the mixed solution described in step (1) at a rotational speed of 9000rpm for 10min, control the temperature of the centrifugation at 10°C, and collect the centrifuged supernatant after centrifugation for 3 times;

[0040] (3) Put the suspension described in step (2) into a dialysis bag with a molecular weight of 14000 for dialysis until the suspension is neutral;

[0041] (4) Centrifuge the neutral suspension described in step (3) at 10000rpm for 8min, control the temperature of the centrifuge at 10°C, collect the lower sediment after centrifugation for 3 times, and then dilute to obtain ...

Embodiment 2

[0045] A preparation method for a flexible cellulose liquid crystal film, comprising the steps of:

[0046] (1) Mix 100g microcrystalline cellulose with 100ml 62wt% concentrated sulfuric acid solution, under stirring conditions (stirring rate is 300rpm), treat at 55°C for 50min, add 1000ml deionized water, mix well and let stand for 12h;

[0047] (2) Centrifuge the mixed solution described in step (1) at a rotational speed of 9000 rpm for 9 minutes, control the temperature of the centrifugation at 10° C., and collect the centrifuged supernatant after centrifugation for 3 times;

[0048] (3) Put the suspension described in step (2) into a dialysis bag with a molecular weight of 14000 for dialysis until the suspension is neutral;

[0049] (4) Centrifuge the neutral suspension described in step (3) at a speed of 10000rpm for 9min, control the temperature of the centrifugal treatment at 10°C, collect the lower sediment after centrifugation for 3 times, and then dilute to obtain a ...

Embodiment 3

[0053] A preparation method for a flexible cellulose liquid crystal film, comprising the steps of:

[0054] (1) Mix 100g microcrystalline cellulose with 100ml 66wt% concentrated sulfuric acid solution, under stirring conditions (stirring rate is 300rpm), treat at 55°C for 50min, add 1200ml deionized water, mix well and let stand for 12h;

[0055] (2) Centrifuge the mixed solution described in step (1) at a speed of 9000 rpm for 8 minutes, control the temperature of the centrifugation at 5° C., and collect the centrifuged supernatant after centrifugation for 3 times;

[0056] (3) Put the suspension described in step (2) into a dialysis bag with a molecular weight of 14000 for dialysis until the suspension is neutral;

[0057] (4) Centrifuge the neutral suspension described in step (3) at a speed of 10,000 rpm for 10 minutes, control the temperature of the centrifugal treatment at 10° C., collect the lower sediment after centrifugation for 3 times, and then dilute to obtain a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com