Cast-in-situ bored pile static pressure test pile head one-time pouring construction method

A technology of bored piles and construction methods, which can be applied to foundation structure tests, buildings, and sheet pile walls, etc., which can solve problems such as long construction periods, waste of materials, and increased labor costs, so as to improve construction efficiency and ensure construction quality , Improve the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

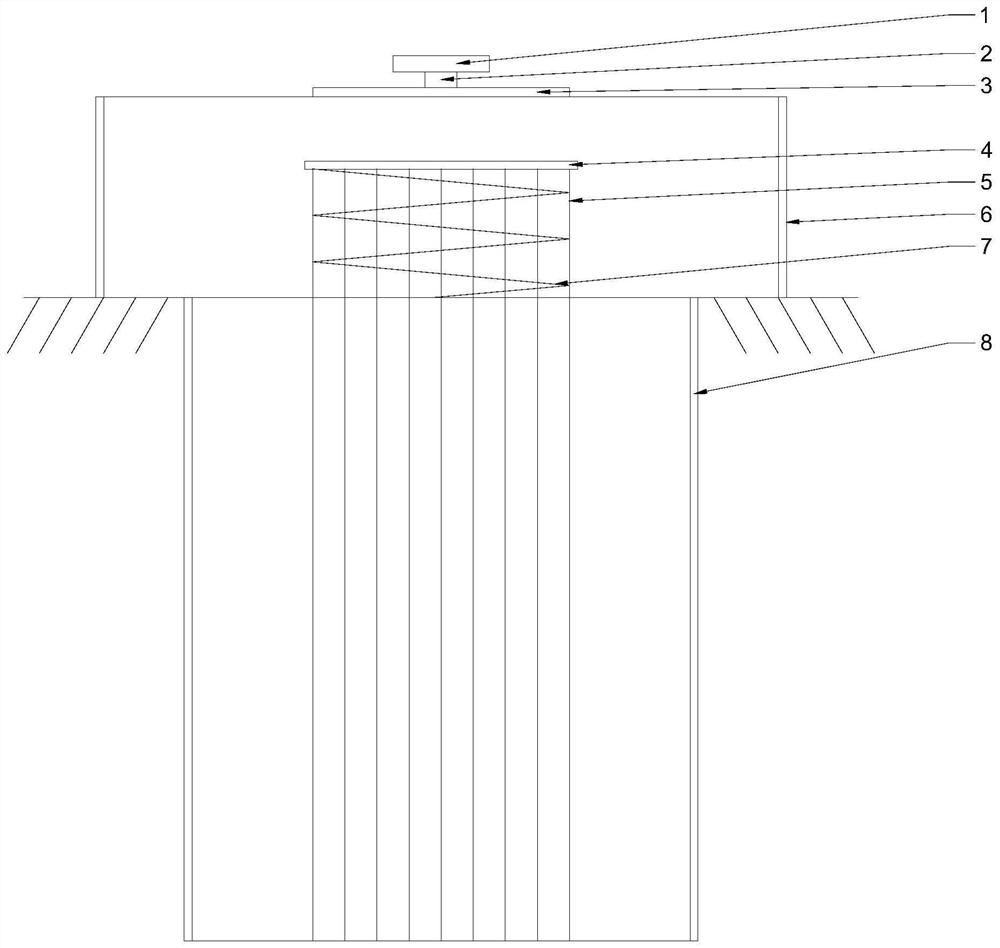

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0027] like figure 1 As shown, the construction method of one-time pouring of the static pressure test pile head of a kind of bored cast-in-place pile provided in the present embodiment comprises the following steps:

[0028] S1. Install the hole-forming steel casing 8 in the hole of the cast-in-situ pile that has been drilled to prevent the rock and soil around the hole wall of the cast-in-place pile from falling into the hole of the cast-in-situ pile and protect the wall of the hole;

[0029] S2. Design the size of the reinforcement cage according to the length of the bored pile to ensure that the top surface of the reinforcement cage is 50cm above the ground;

[0030] S3. After the hole-forming acceptance of the bored pile in step S1 is qualified, install the designed and manufactured reinforcem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com