Shield equipment capable of realizing underground docking and docking method

A technology of shield tunneling and equipment, applied in mining equipment, underground chambers, shaft equipment, etc., can solve the problems of poor sealing effect and low docking efficiency of shield tunneling, so as to facilitate dismantling in the tunnel, improve construction safety factor, The effect of improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

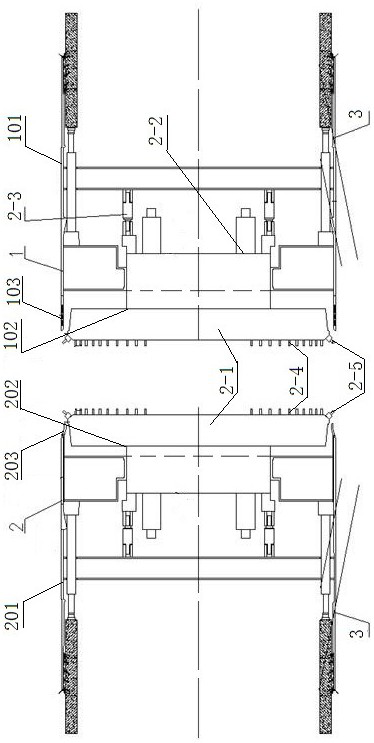

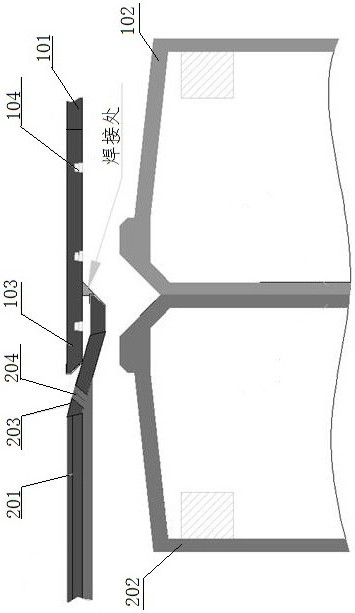

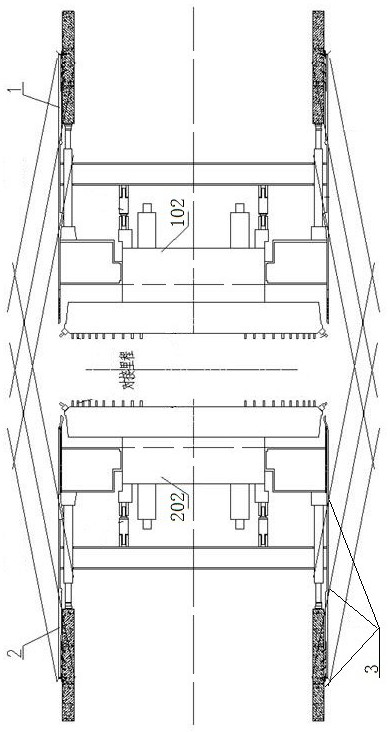

[0034] Embodiment 3: A docking method of shield equipment that can realize underground docking, the steps are as follows:

[0035] S1: The radially telescopic gage knife 2-5 on the axially telescopic cutter head Ⅰ102 of the receiving side shield 1 is retracted in the radial direction, the atmospheric pressure cutter 2-4 is removed, and the telescopic drive mechanism 2-3 drives the axial The telescopic cutter head Ⅰ 102 is retracted as a whole; that is, the axial telescopic cutter head Ⅰ is retracted into the first shield body to avoid interference with the penetration side shield and facilitate the smooth docking;

[0036] S2: The shield machine 2 on the penetrating side continues to excavate and arrives within the set distance L from the shield machine 1 on the receiving side; that is, it excavates forward to a smaller distance L from the axial telescopic cutter head Ⅰ (L=5mm The value range of ~100mm can also be adjusted according to the actual construction conditions);

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com