Textile machinery supporting device

A technology of textile machinery and supporting devices, which is applied in the direction of textile, looms, mechanical equipment, etc. It can solve the problems of no shock-absorbing structure, the inability to deal with the dust of textile machinery, and the failure of textile machinery vibration, so as to achieve good filtration and shock resistance effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

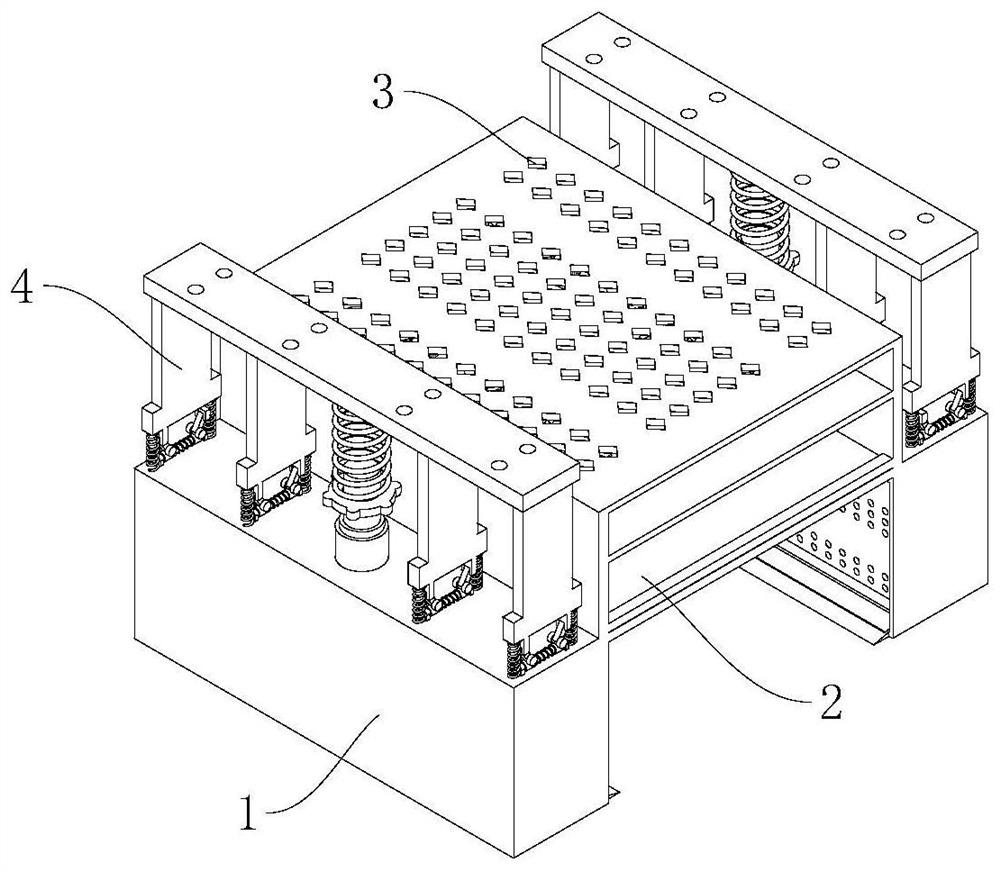

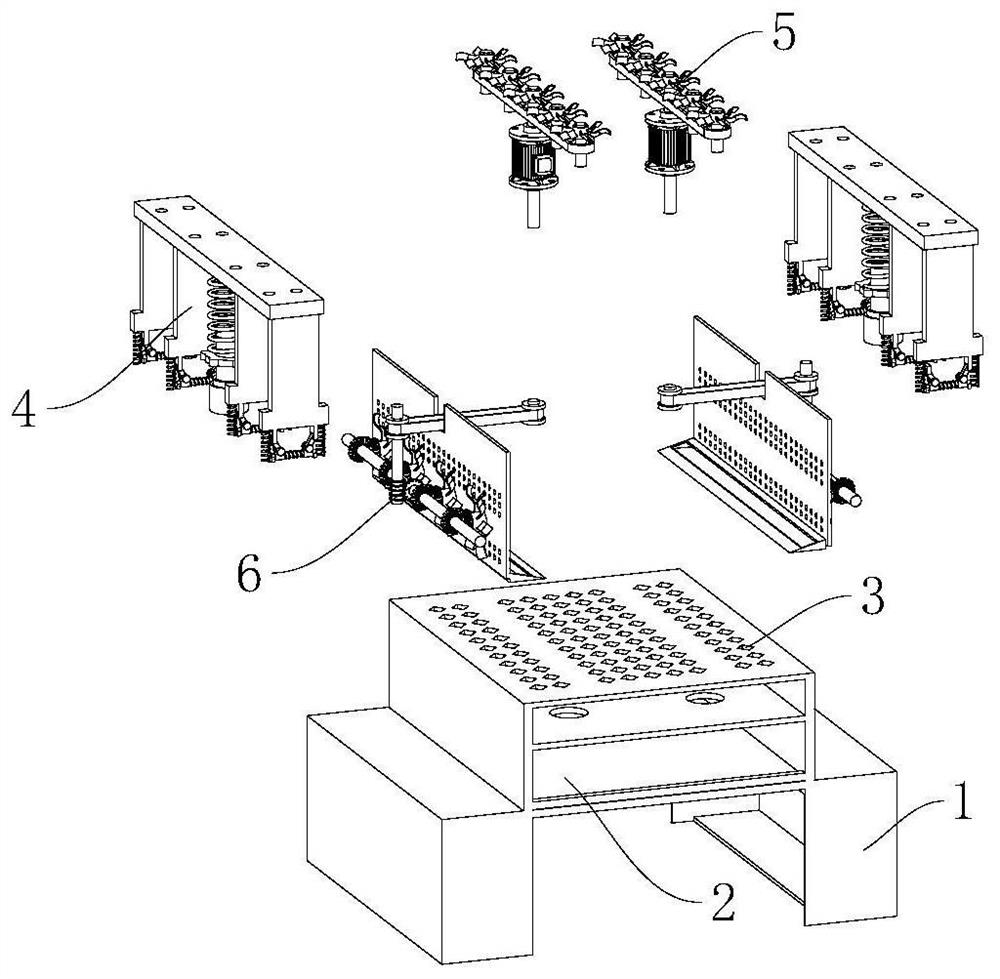

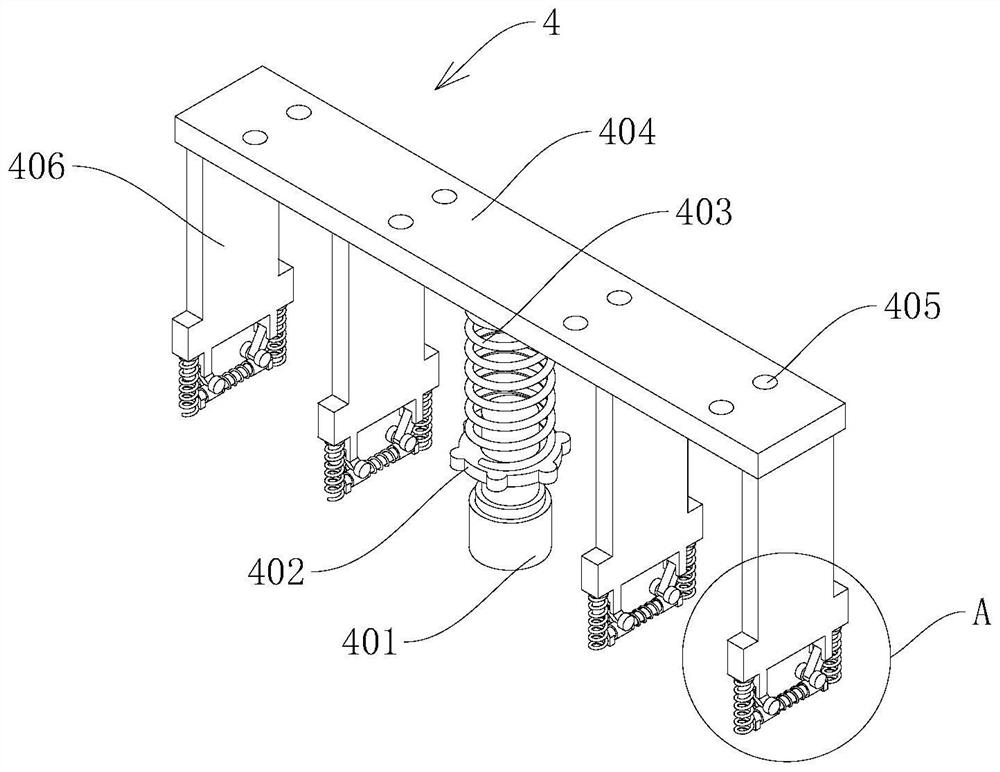

[0029] see Figure 1-4 , a textile machinery support device, including a support base 1 and a mounting frame 2, the mounting frame 2 is fixedly connected to the top of the support base 1, the top surface of the mounting frame 2 is provided with air holes 3, the top ends of the support base 1 It is connected with an adjustable shock-absorbing device 4, and the adjustable shock-absorbing device 4 includes a fixed rod 401. The fixed rod 401 is fixedly connected to the top surface of the support base 1. The fixed rod 401 is screw-connected with an adjustment disc 402, and the fixed rod 401 is also covered with Connected with a first damping spring 403, the bottom end of the first damping spring 403 is in contact with the adjustment plate 402, the top end of the first damping spring 403 is fixedly connected with the textile machine mounting plate 404, and the textile machine mounting plate 404 is provided with a mounting hole 405, the bottom surface of the textile machinery mountin...

Embodiment 2

[0034] see Figure 5 , the difference with the basis of Embodiment 1 is that the drive cooling mechanism 5 includes a biaxial servo motor 501, the biaxial servo motor 501 is fixedly connected inside the installation frame 2, and the upper end output shaft of the biaxial servo motor 501 is fixed Connected with a driving shaft 502, the driving shaft 502 is fixedly connected with a drive gear 503, the two sides of the driving shaft 502 are provided with a driven shaft 504, the driven shaft 504 is rotatably connected to the mounting frame 2, and the driven shaft 504 is fixedly connected with The driven gear 505, the driving gear 503 and the driven gear 505 are meshed with a linkage chain 506, and the tops of the driving shaft 502 and the driven shaft 504 are fixedly connected with a cooling fan blade 507, and the cooling fan blade 507 is arranged on the top surface of the installation frame 2 Below the ventilation hole 3.

[0035] The driving heat dissipation mechanism 5 of the p...

Embodiment 3

[0037] see Image 6 , the difference with the basis of Embodiment 1 is that the linkage dust suction mechanism 6 also includes a first belt pulley 601 and a second belt pulley 602, and the first belt pulley 601 is fixedly connected to the output of the lower end of the double-axis servo motor 501 On the shaft, the second belt pulley 602 is rotatably installed inside the support base 1, the first belt pulley 601 and the second belt pulley 602 are connected with a linkage belt 603, and the bottom end of the second belt pulley 602 is fixedly connected with a worm 604, The worm 604 is meshed with the worm wheel 605 , the worm wheel 605 is fixedly connected to the linkage shaft 606 , and the two ends of the linkage shaft 606 are rotatably connected to the inner side wall of the support base 1 .

[0038] The linkage shaft 606 is fixedly connected with a first bevel gear 607, the first bevel gear 607 is meshed with the second bevel gear 608, and the second bevel gear 608 is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com