Dryer for chemical reagent production

A technology of chemical reagents and dryers, which is applied in the direction of drying solid materials, dry cargo handling, non-progressive dryers, etc., can solve the problems of low drying efficiency and drying blind spots, reduce heating blind spots, improve drying efficiency, and realize quantitative collection of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

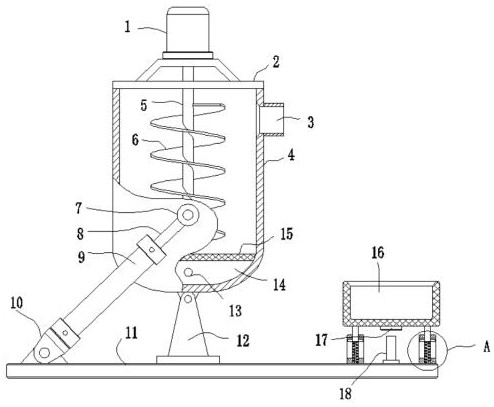

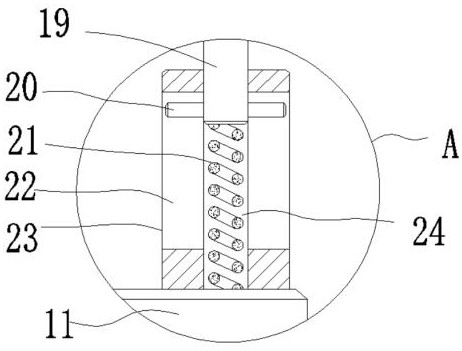

[0022] Such as Figure 1-2 As shown, a dryer for the production of chemical reagents includes a base 11, on which a fixed hinge base 12 is arranged, and a drying chamber 4 for storing chemical reagents is hingedly mounted on the fixed hinge base 12 , the bottom of the drying bin 4 is hinged with the fixed hinge base 12, so that the drying bin 4 can rotate, and the base 11 is provided with a swing drive assembly for driving the drying bin 4 to rotate along the hinge with the fixed hinge base 12 , the drying chamber 4 is provided with a partition 15, a heat transfer oil storage space 14 for storing heat transfer oil is enclosed between the partition 15 and the inner bottom wall of the drying chamber 4, and the top of the drying chamber 4 is open And the cover plate 2 that is used to close its inside is detachably installed, and the stirring motor 1 is installed on the cover plate 2 through the bracket, and the stirring shaft 5 is driven and connected to the stirring motor 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com