A method for detecting and calibrating the psd angle of the incident point non-rotating origin

An angle detection and calibration method technology, applied in the detection field, can solve problems such as high cost, not suitable for mass production, and inability to achieve accurate measurement, and achieve the effect of convenient calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

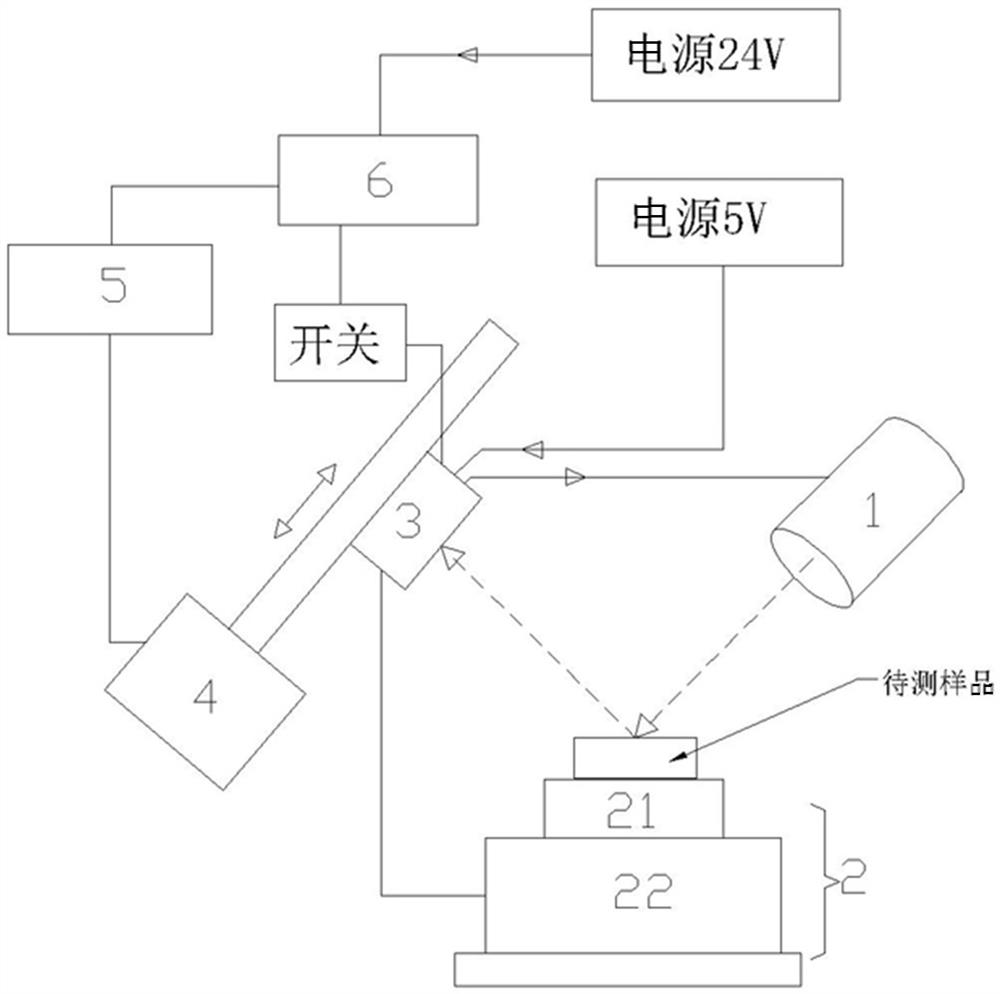

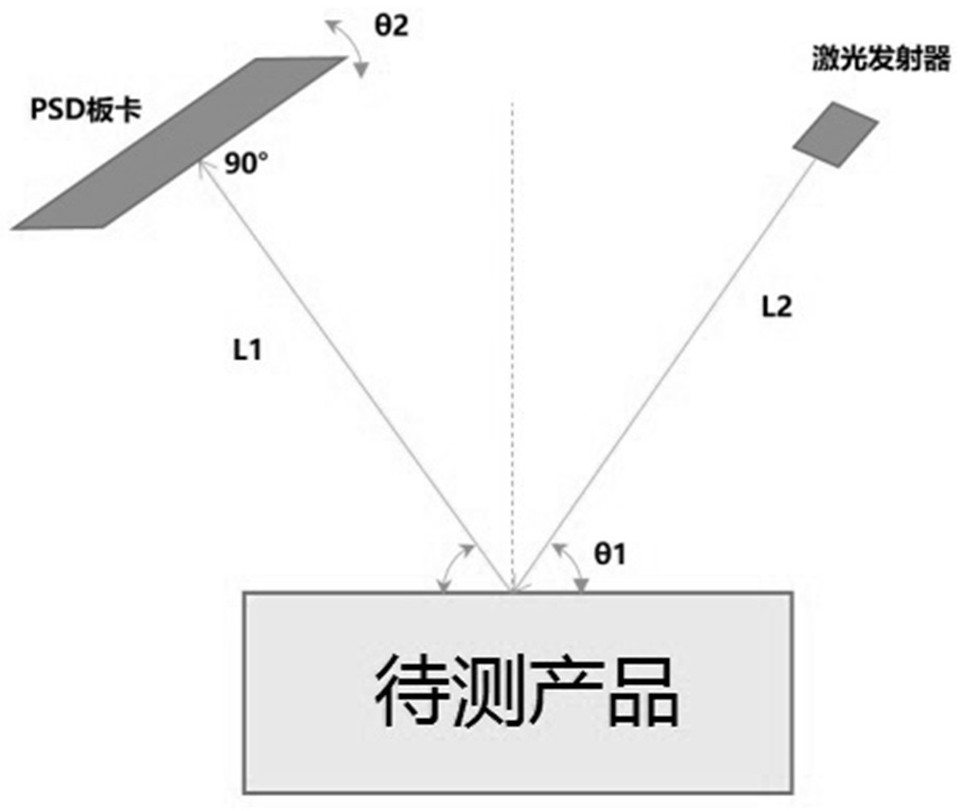

[0052] Such as figure 1 As shown, the present invention is realized by the photoelectric sensor angle detection system, and the photoelectric sensor angle detection system includes a laser transmitter 1, a product machine 2, a PSD board 3, and the product to be tested is positioned on the product machine 2, and the external force The product to be tested is driven to rotate, and the PSD board 3 is set by a moving motor 4 . The moving motor 4 is electrically connected with a PLC controller 6 through a motor driver 5 . The product machine 2 also includes a workbench, a clamp 21 and a signal acquisition module 22, the signal acquisition module 22 is fitted on the lower side of the clamp 21, and the signal acquisition module 22 is electrically connected to the PLC controller 6 . The PLC controller 6 is externally connected to a 24V power supply. The laser transmitter 1 and the PSD board 3 are powered by a 5V power supply. The laser transmitter 1 irradiates the product to be te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com