The whole process temperature field calculation system of hot-rolled bar and wire based on rolling schedule

A technology of calculation system and temperature field, applied in manufacturing calculation system, calculation, temperature control, etc., can solve problems such as calculation method and system of temperature evolution in the whole process of rods and wires that have not yet been consulted, and achieve the effect of comprehensive calculation basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

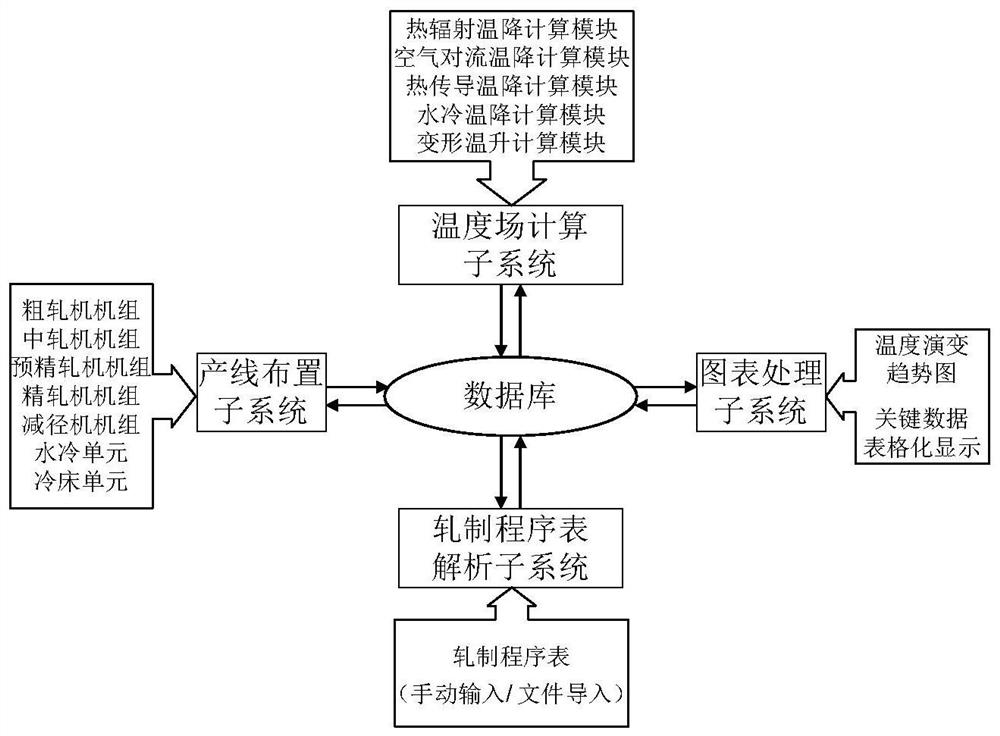

[0037] The present invention is a full-process temperature field calculation system for hot-rolled bars and wires based on a rolling program table, and the specific implementation steps are as follows:

[0038] Step 1. In the rolling program table module, input the rolling program data of different specifications under each production line as the basic data of the subsequent modules.

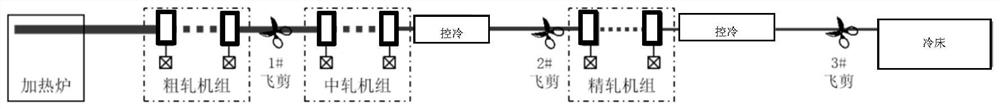

[0039] Step 2: The production line layout module splits the production line into multiple process units (roughing mill unit, intermediate rolling mill unit, pre-finishing mill unit, finishing mill unit and reducing mill unit, water cooling unit and cooling unit. bed unit), and provide input parameter configuration for each process unit, the user can select the corresponding process unit to combine according to different production lines.

[0040] Step 3: In the temperature evolution module of the whole process, the data of the rolling program table is directly used for calculation in offline cal...

Embodiment 2

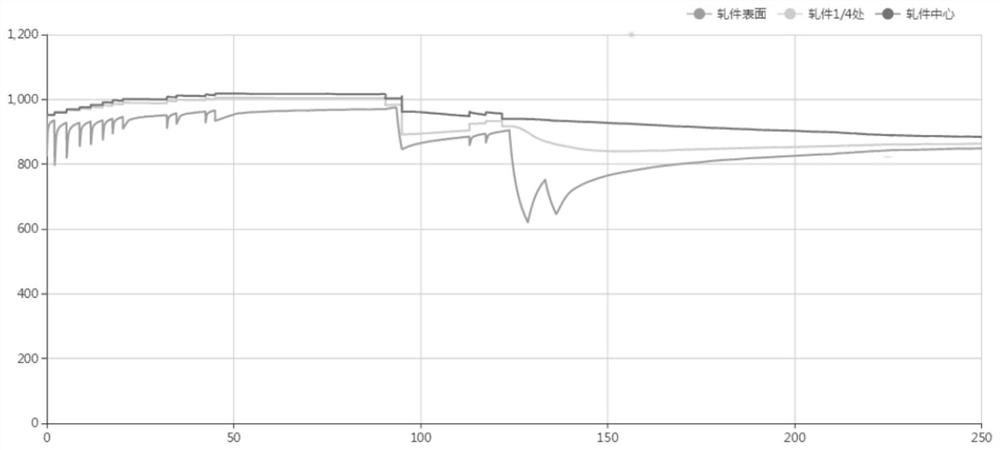

[0042] Take a bar factory The rolling program table (single-line rolling) of threaded steel bars is used as an example to calculate. The plant has a total of 18 rolling mills. There is one set of controlled chilled water tanks behind the intermediate rolling mill and two controlled chilled tanks behind the finishing mill. The cooling bed is 12m wide and 110m long. Users first directly import in the form of an Excel table See Table 1 for the rolling program table of threaded bars (you can also enter data manually in the parameter input window).

[0043] The rolling program table analysis subsystem reads the imported rolling program table data (Table 1), and recognizes that the front 6 stands of the production line are rough rolling mills (RS), the middle 6 stands are medium rolling mills (MS), The rear 6 stands are the finishing mill unit (FS), and at the same time identify the spacing value of each stand, the type of pass, the flat state of the rolling mill, the reduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com