Method, device and equipment for determining stress condition of tubular column

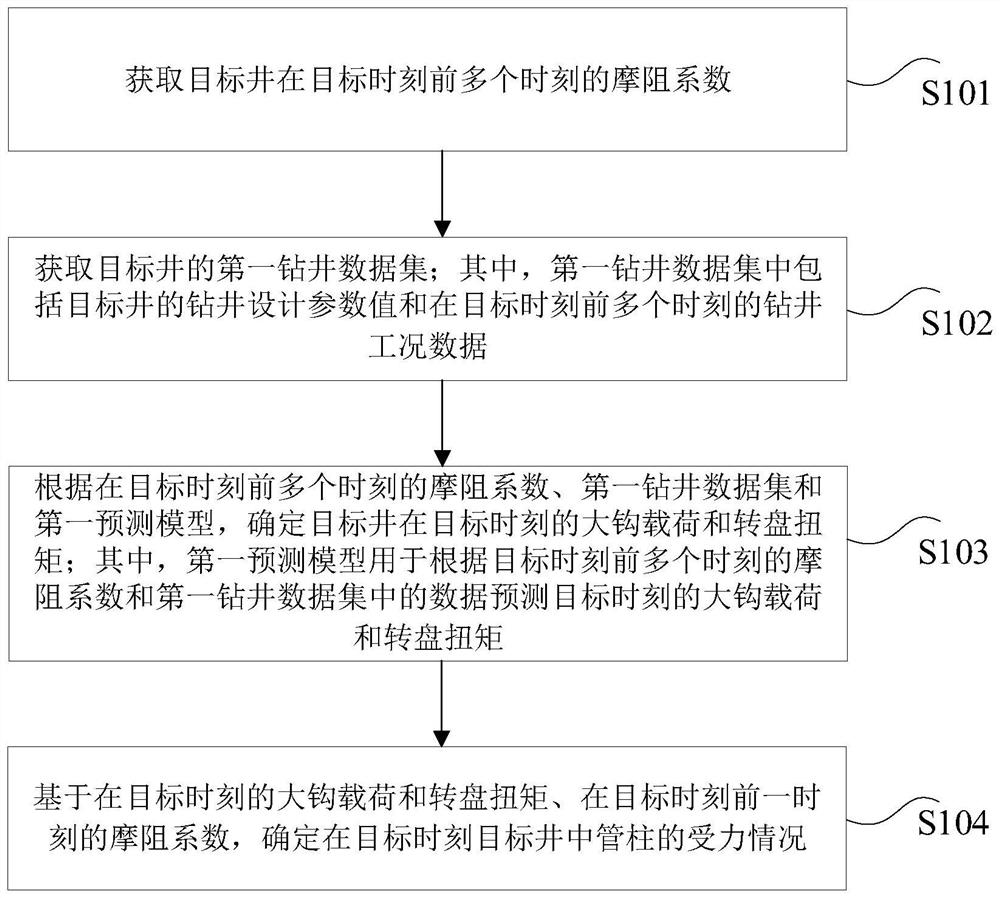

A technology of pipe string and working condition data, which is applied in the field of geological exploration and can solve problems such as the inability to accurately determine the force of the downhole pipe string

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

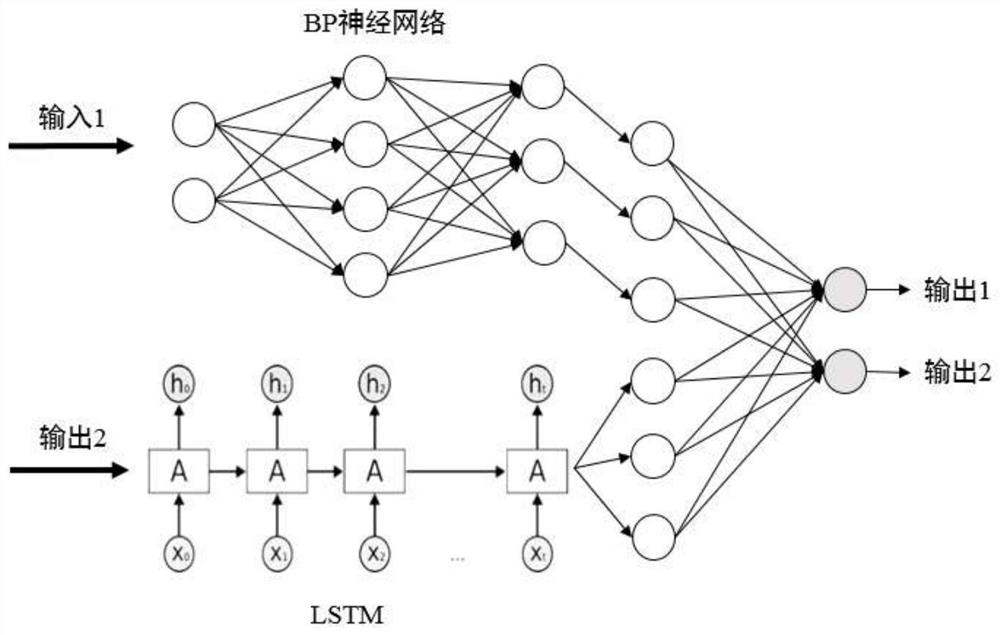

Method used

Image

Examples

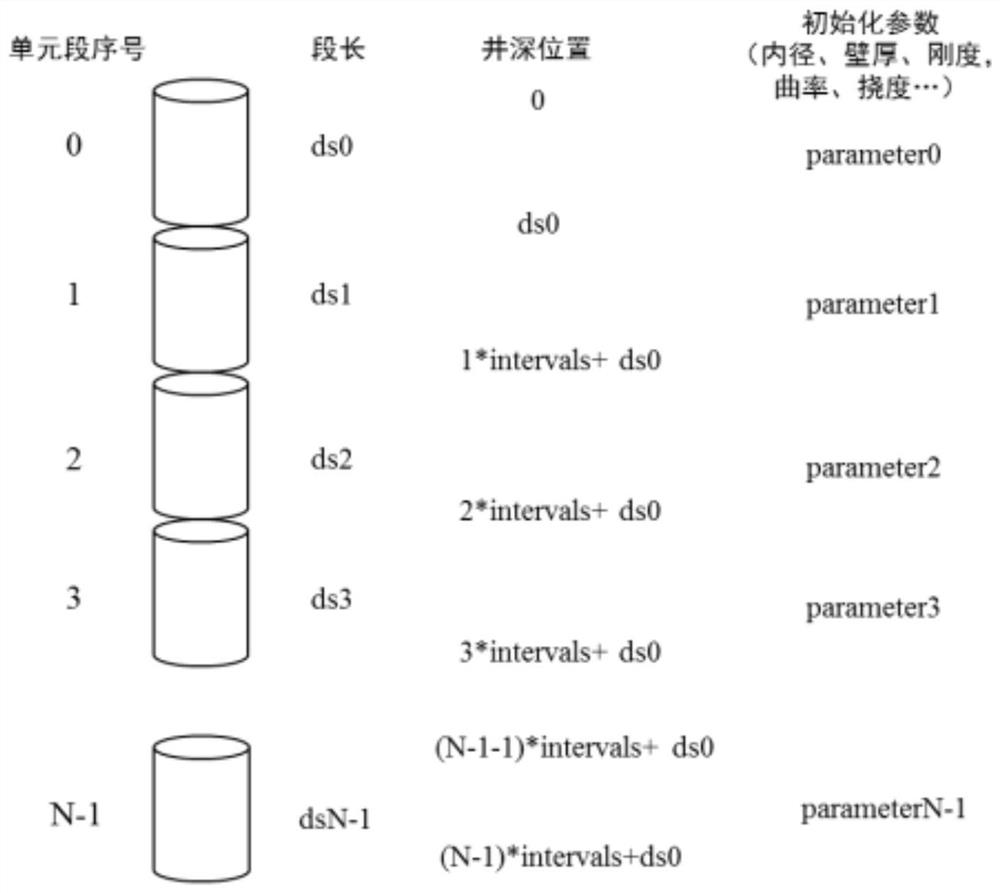

Embodiment Construction

[0022] The principle and spirit of the embodiments of this specification will be described below with reference to several exemplary implementations. It should be understood that these implementations are given only to enable those skilled in the art to better understand and implement the embodiments of the present specification, but not to limit the scope of the embodiments of the present specification in any way. On the contrary, these embodiments are provided to make the disclosure of the embodiments of this specification more thorough and complete, and to fully convey the scope of the present disclosure to those skilled in the art.

[0023] Those skilled in the art know that the implementation of the embodiments in this specification can be implemented as a system, device, method or computer program product. Therefore, the embodiments disclosed in this specification can be specifically implemented in the following forms: complete hardware, complete software (including firm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com