Large-size solar cell structure packaging assembly

A solar cell and packaging module technology, applied in the field of solar cells, can solve problems such as photoelectric conversion efficiency reduction, module power reduction, cutting edge damage, etc., and achieve the effects of reducing ribbon resistance, module power improvement, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

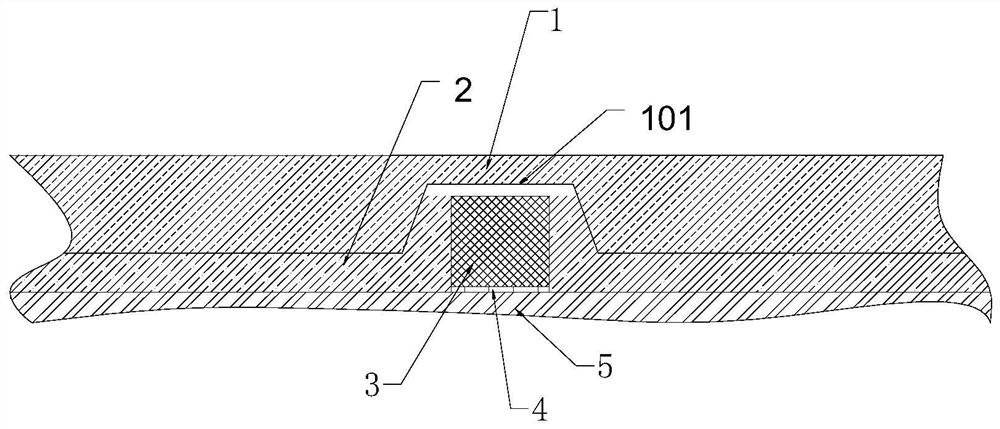

[0021] like figure 1 As shown, this embodiment provides a battery chip interconnection packaging assembly with a side length of 156.75 mm in large size. Each battery assembly includes at least packaging glass 1, packaging film 2, thickened solder ribbon 3 and battery sheet 5 from top to bottom. Each battery sheet contains five main grid lines 4, and the packaging glass 1 is provided with a set of trapezoidal grooves 101 in parallel along the length direction of the main grid lines 4. The positions of the main grid lines and the trapezoidal grooves correspond one by one. The thickened solder ribbon 3 is embedded in the trapezoidal groove 101 of the packaging glass 1 and has a gap with the surrounding inner wall of the trapezoidal groove.

[0022] In this embodiment, when the cells are interconnected, the width of the ribbon is 0.77 mm, the thickness of the ribbon is 1.2 mm, the glass groove is trapezoidal, the depth is 1.4 mm, the bottom width of the groove is 2 mm, and the sur...

Embodiment 2

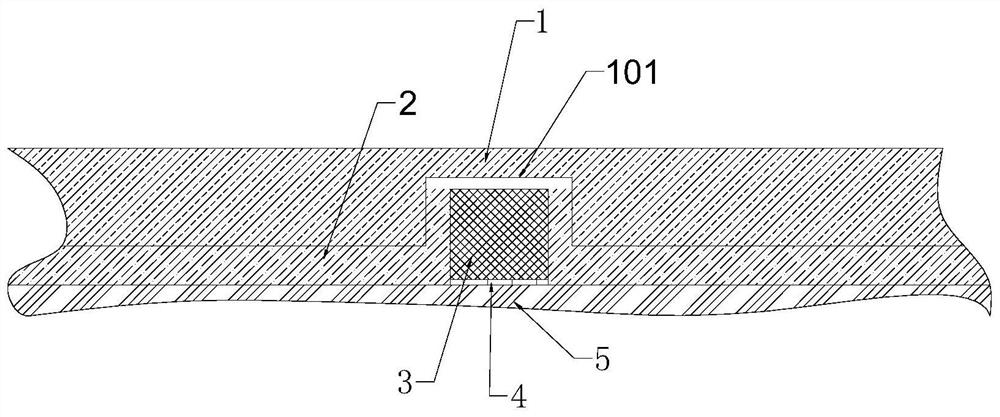

[0025] like figure 2 As shown: this embodiment is illustrated by taking the interconnection assembly of 210 mm side length battery slices as an example. The composition of the basic components is similar to that of the embodiment. The difference between the welding ribbon 3 and the battery sheet 5 is that eight busbars 4 are respectively arranged on the battery sheet 5 in this embodiment, and when the battery sheets are interconnected, the width of the welding ribbon is increased by 0.6 mm and the thickness is 1 mm.

[0026] The groove 101 of the encapsulating glass 1 in this embodiment is rectangular, the length of the rectangle is 2 mm, and the width is 1.2 mm. The components interconnected in this way do not increase the cost of solder ribbon materials. Module power increased by at least 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com