Aquatic feed as well as processing system and method thereof

A technology of aquatic feed and processing system, applied in the direction of feed, animal feed, animal feed, etc., can solve the problems of inability to prepare aquatic feed, achieve the effect of accelerating drying speed and increasing heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

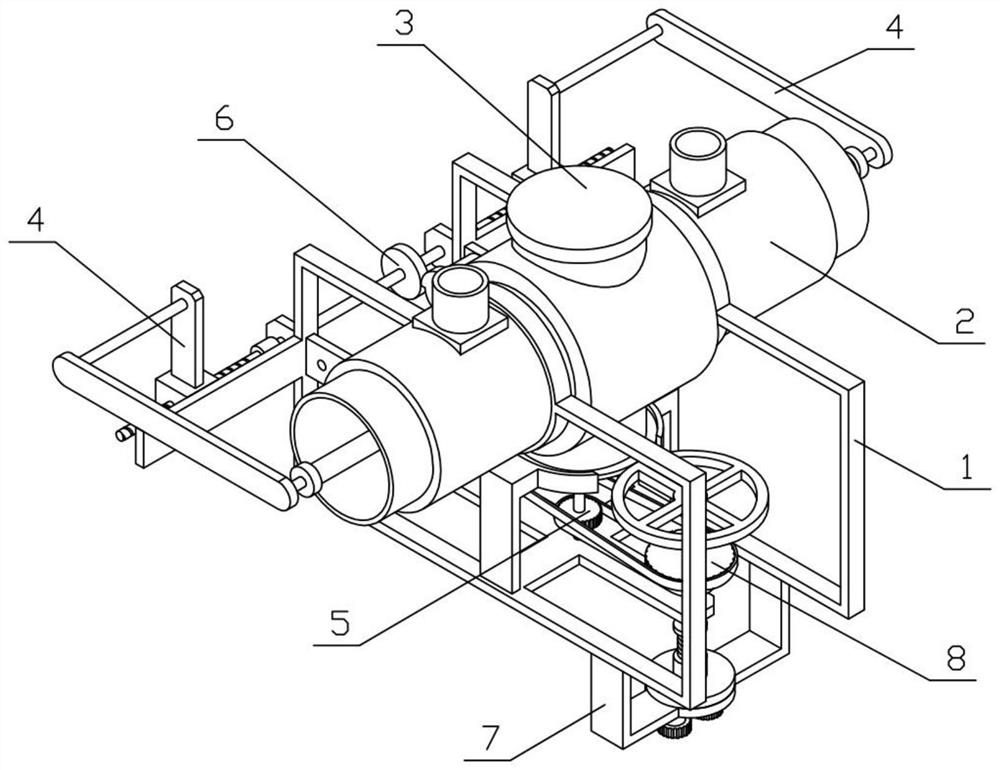

[0040] Combine below Figures 1 to 12 Description of this embodiment, an aquatic feed processing system, including a device support 1, an extrusion support 2, a perforation mechanism 3, an extrusion mechanism 4 and a forming mechanism 5, an extrusion support 2 is fixedly connected to the device support 1, and an extrusion support 2 is fixedly connected to the device support 1. The middle part of the pressing bracket 2 is fixedly connected with a perforating mechanism 3, and the device bracket 1 is connected with two extruding mechanisms 4. On the device support 1 , the upper end of the molding mechanism 5 is in contact with the middle part of the extruding support 2 .

specific Embodiment approach 2

[0042] Combine below Figures 1 to 12 Describe this embodiment, this embodiment will further explain Embodiment 1, the device bracket 1 includes a side bracket 101, a bottom bracket 102, a rotating side plate 103 and a limit slide rail 104, and the side bracket 101 is provided with two, two A bottom bracket 102 is fixedly connected between the lower ends of the side brackets 101 , a rotating side plate 103 is fixedly connected to the middle of the two side brackets 101 , and a limit slide rail 104 is fixedly connected to the rear ends of the two side brackets 101 .

specific Embodiment approach 3

[0044] Combine below Figures 1 to 12 Describe this embodiment, this embodiment will further explain the second embodiment, the extrusion bracket 2 includes an extrusion cylinder 201, a discharge cylinder 202, an installation cylinder 203 and an inlet cylinder 204, and the lower end of the middle part of the extrusion cylinder 201 is fixed The discharge cylinder 202 is connected, the upper end of the extrusion cylinder 201 is fixedly connected with the installation cylinder 203, the extrusion cylinder 201 is fixedly connected with the feed cylinder 204, the extrusion cylinder 201 is fixedly connected between the two side brackets 101, and the extrusion A heating mechanism is arranged inside the pressing cylinder 201 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com