Mining coal crusher

A coal crusher and mining technology, applied in application, use of liquid separation agent, food science, etc., can solve problems such as inability to crush coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

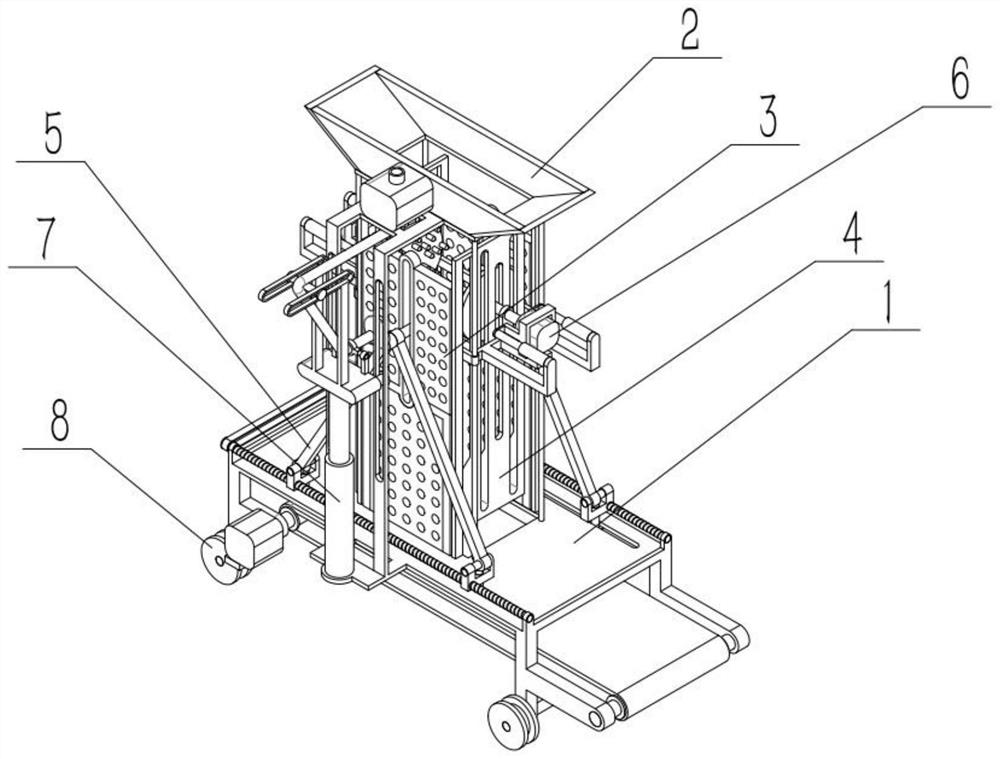

[0032] like Figure 1-10 As shown, a mining coal crusher includes a base structure 1, a feed seat 2, a side baffle 3, a main baffle 4, a linkage mechanism 5, a coal crushing mechanism 6, a dust reduction mechanism 7 and a wheel mechanism 8. The feeding seat 2 is connected to the upper end of the base structure 1, and two side baffles 3 are provided. The two side baffles 3 are respectively connected to the front and rear ends of the middle part of the base structure 1, and the left and right ends of the middle part of the base structure 1 are respectively mirrored and symmetrically connected. A main baffle plate 4, the linkage mechanism 5 is connected to the middle part of the base structure 1, the left and right ends of the linkage mechanism 5 are respectively mirrored and symmetrically connected to a coal crushing mechanism 6, the dust suppression mechanism 7 is connected to the rear end of the base structure 1, and the wheel mechanism 8 is provided with Two, two wheel mechan...

specific Embodiment approach 2

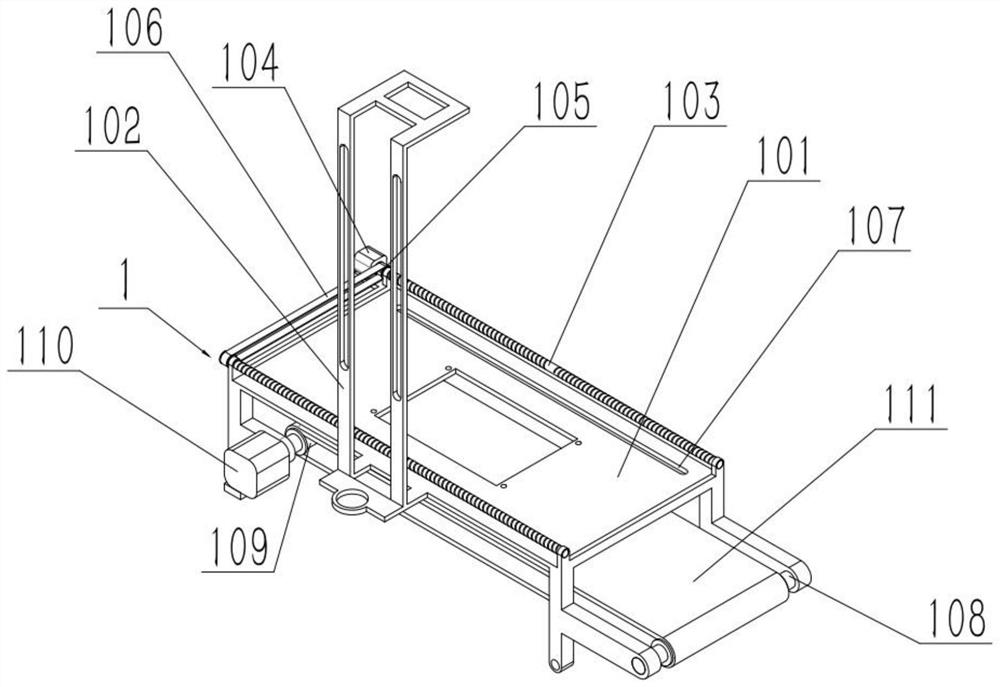

[0034] like Figure 1-10As shown, a mining coal crusher, the base structure 1 includes a base 101, a limit plate 102, a screw 103, a first motor 104, a first pulley 105, a first belt 106, and a limit bar hole 107 , the rotating rod 108, the second pulley 109, the second motor 110 and the second belt 111, the limit plate 102 is fixedly connected to the rear end of the base 101, and the front and rear ends of the base 101 are respectively rotated and connected to a lead screw 103, the first The output shaft of the motor 104 is fixedly connected to the leading screw 103 at the front end through a coupling, and the left end of each leading screw 103 is fixedly connected to a first pulley 105 respectively, and the two first pulleys 105 are connected through a first belt 106 transmission, The first motor 104 is fixedly connected to the left end of the base 101, and the front and rear sides of the base 101 are respectively provided with a limit bar hole 107, and the left and right en...

specific Embodiment approach 3

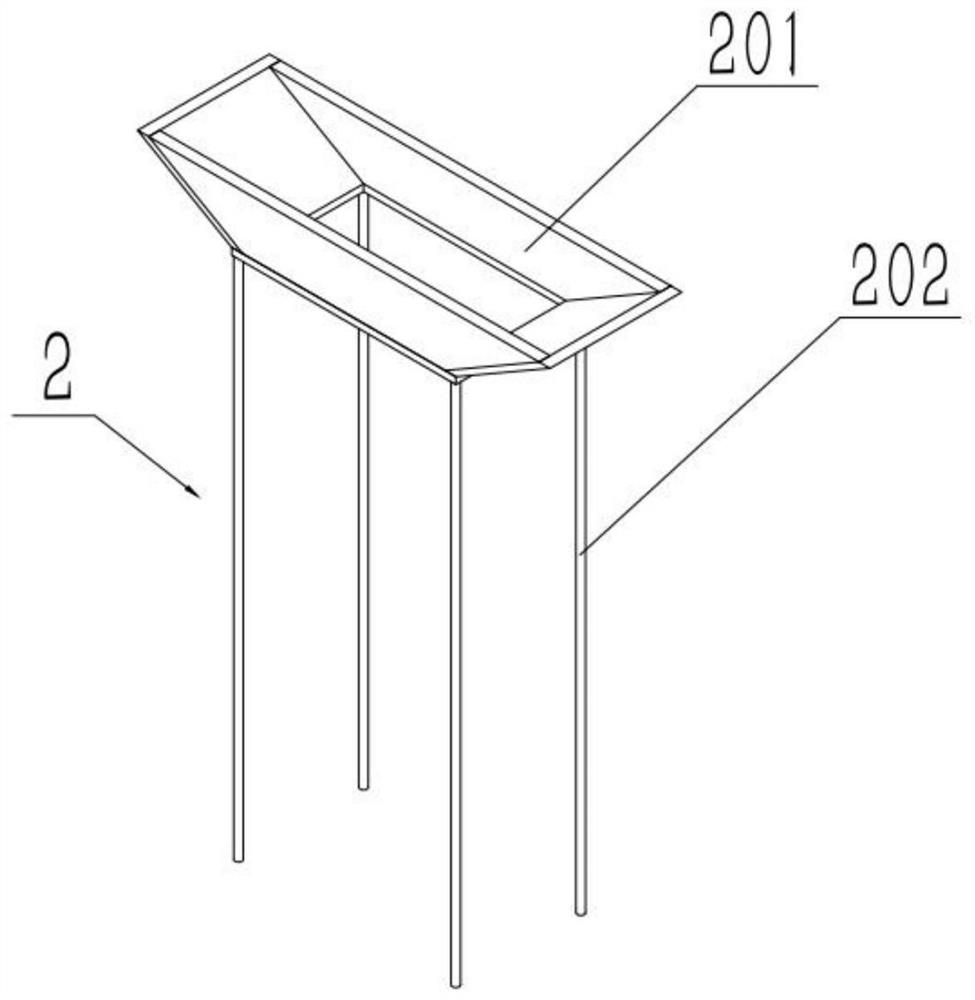

[0036] like Figure 1-10 As shown, a mine coal crusher, the feeding seat 2 includes a feeding chute 201 and a sliding rod 202, the four corners of the bottom end of the feeding chute 201 are fixedly connected to a sliding rod 202, and the lower ends of the four sliding rods 202 are It is fixed in the middle of the base 101. In the coal mine, the coal lumps of the coal mine are fed into the chute 201 to facilitate subsequent coal crushing treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com