Drilling machine for steel pipe machining

A kind of mechanical processing and drilling machine technology, applied in the direction of boring/drilling, metal processing equipment, drilling/drilling equipment, etc., can solve the problems of low production efficiency, inconvenient operation, high labor intensity, etc., and achieve maintenance cost Low cost, labor-saving and convenient operation, convenient installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

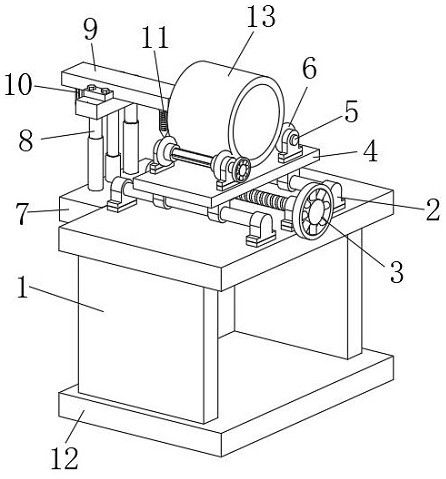

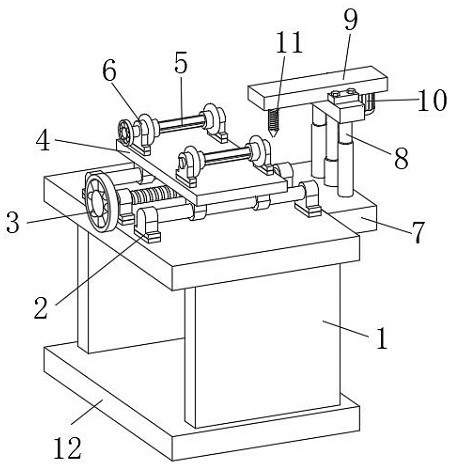

[0036] A drilling machine for mechanical processing of steel pipes, such as Figure 1-2As shown, including the console 1, the upper end of the console 1 is fixedly installed with six No. 1 fixing seats 2, and the two No. 1 fixing seats 2 are distributed in front and back as a group, and the six No. 1 fixing seats 2 are connected together. There is a pushing mechanism 3, and the upper part of the pushing mechanism 3 is threadedly connected with a fixed frame 4, and the left and right sides of the upper part of the fixed frame 4 are jointly movable connected with an adjusting mechanism 5, and the left and right sides of the adjusting mechanism 5 are fixedly installed with two Transmission wheel 6, and the two transmission wheels 6 are symmetrically distributed front and rear, a steel pipe main body 13 is clamped together between the four transmission wheels 6, a fixed plate 7 is fixedly installed on the rear end of the console 1, and the upper end of the fixed plate 7 A lifting ...

Embodiment 2

[0039] On the basis of Example 1, as Figure 3-6 As shown, a drilling machine for mechanical processing of steel pipes includes an operating table 1, and six No. 1 fixing seats 2 are fixedly installed on the upper end of the operating table 1, and two No. 1 fixing seats 2 are arranged in front and back as a group. A push mechanism 3 is jointly connected between the No. 1 fixed seats 2, and the upper part of the push mechanism 3 is threadedly connected with a fixed mount 4, and the upper left and right sides of the fixed mount 4 are jointly movable connected with an adjustment mechanism 5, and the adjustment mechanism 5 Two transmission wheels 6 are fixedly installed on the left and right sides of the left and right sides, and the two transmission wheels 6 are symmetrically distributed front and rear, a steel pipe main body 13 is clamped together between the four transmission wheels 6, and the rear end of the console 1 is fixedly installed with A fixed plate 7, a lifting mechan...

Embodiment 3

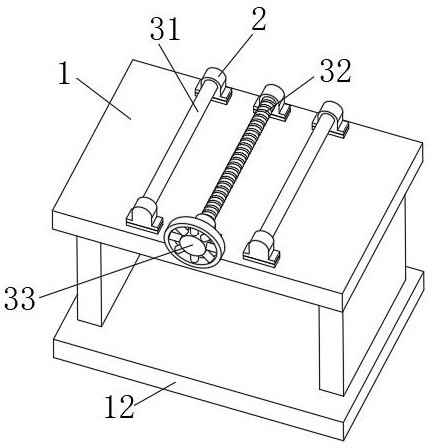

[0042] On the basis of Example 1, as Figure 7-8 As shown, a drilling machine for mechanical processing of steel pipes includes an operating table 1, and six No. 1 fixing seats 2 are fixedly installed on the upper end of the operating table 1, and two No. 1 fixing seats 2 are arranged in front and back as a group. A push mechanism 3 is jointly connected between the No. 1 fixed seats 2, and the upper part of the push mechanism 3 is threadedly connected with a fixed mount 4, and the upper left and right sides of the fixed mount 4 are jointly movable connected with an adjustment mechanism 5, and the adjustment mechanism 5 Two transmission wheels 6 are fixedly installed on the left and right sides of the left and right sides, and the two transmission wheels 6 are symmetrically distributed front and rear, a steel pipe main body 13 is clamped together between the four transmission wheels 6, and the rear end of the console 1 is fixedly installed with A fixed plate 7, a lifting mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com