Electromechanical integrated machining device

A processing device, electromechanical technology, applied in the direction of shearing device, metal processing equipment, accessories of shearing machine, etc., can solve the problems of staying beside the machine all the time, the operator's health is dangerous, and the operation is troublesome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

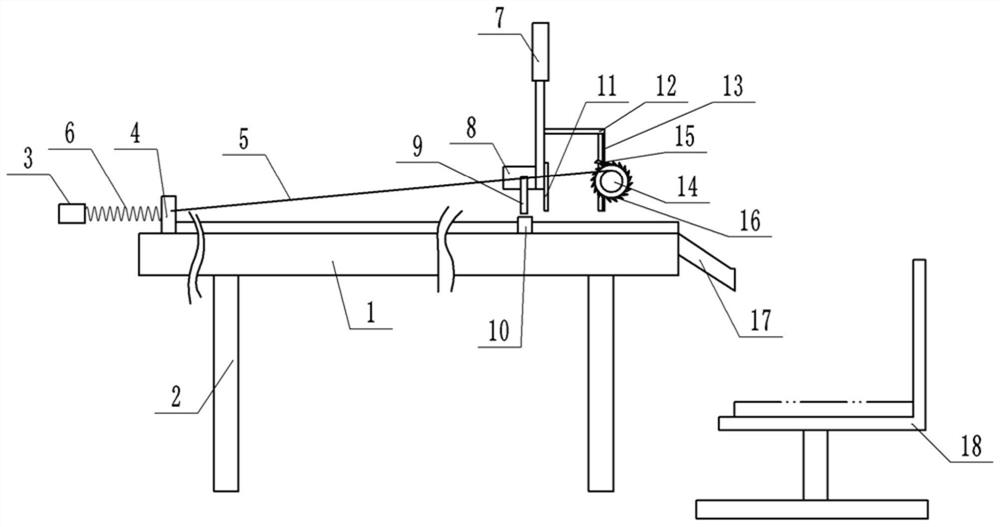

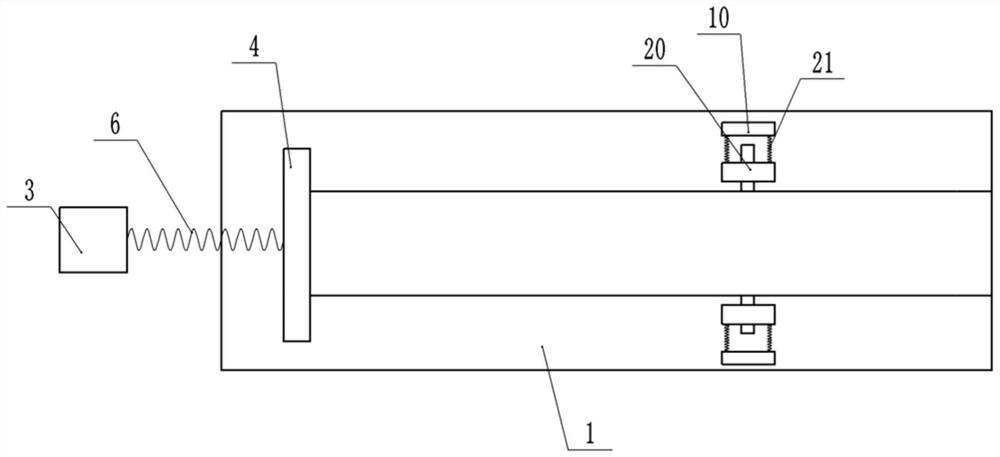

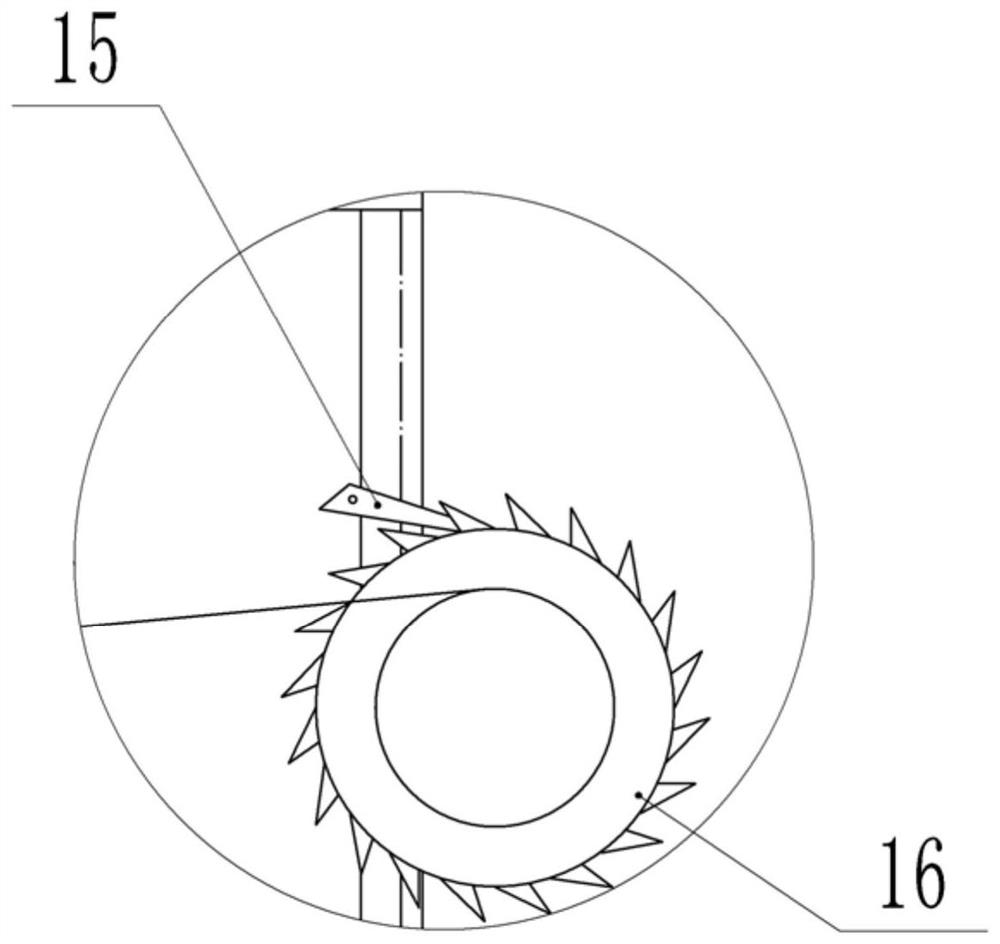

[0027] Basic as attached Figure 1-Figure 5 Shown: a mechanical and electrical integration processing device, including a frame (not shown in the figure), a cutting table 1 and a cutting tool 11, the cutting table 1 is a rectangular parallelepiped structure placed horizontally, and the bottom of the cutting table 1 is welded with a support rod 2. The right end of the cutting table 1 is the discharge end, and the top of the cutting table 1 is provided with a cylinder 7 for driving the cutting tool 11 to reciprocate vertically. The cylinder 7 is fixedly connected to the frame by bolts, and the cylinder rod of the cylinder 7 is fixed by screws. There is a cutting motor 8 for driving the cutting tool 11 to run. The table top of the cutting table 1 is horizontally slidably connected with a push plate 4. The specific sliding connection method can be as follows: the cutting table 1 is provided with a horizontal chute, the bottom of the push plate 4 is provided with a slider, and the...

Embodiment 2

[0035] combine Figure 6 As shown, a first hydraulic cylinder 22 is provided below the collector 18, and a first piston 23 is slidably connected to the inside of the first hydraulic cylinder 22, and a first piston is connected between the first piston 23 and the collector 18 by screws. Rod; the cutting table 1 is fixed with the second hydraulic cylinder 25 arranged horizontally by screws, the opening of the second hydraulic cylinder 25 is located at the right end, and the inside of the second hydraulic cylinder 25 is slidingly connected with the second piston 26, the second The piston 26 is fixedly connected with the second piston rod 28 arranged horizontally by screws, the right end of the second piston rod 28 and the push plate 4 are connected with a bent connecting rod 27, the second hydraulic cylinder 25 and the first hydraulic cylinder An oil pipe 24 is communicated between the cylinders 22 .

[0036] Thus, initially, the bottom of the collector 18 is slightly lower than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com