Traction type front-back two-way chute device used for bulk materials

A traction-type technology for bulk materials, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of bulk material dust, bulk material leakage, environmental pollution, etc., to improve loading efficiency, high stability, and avoid partial load and concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained by specific examples below.

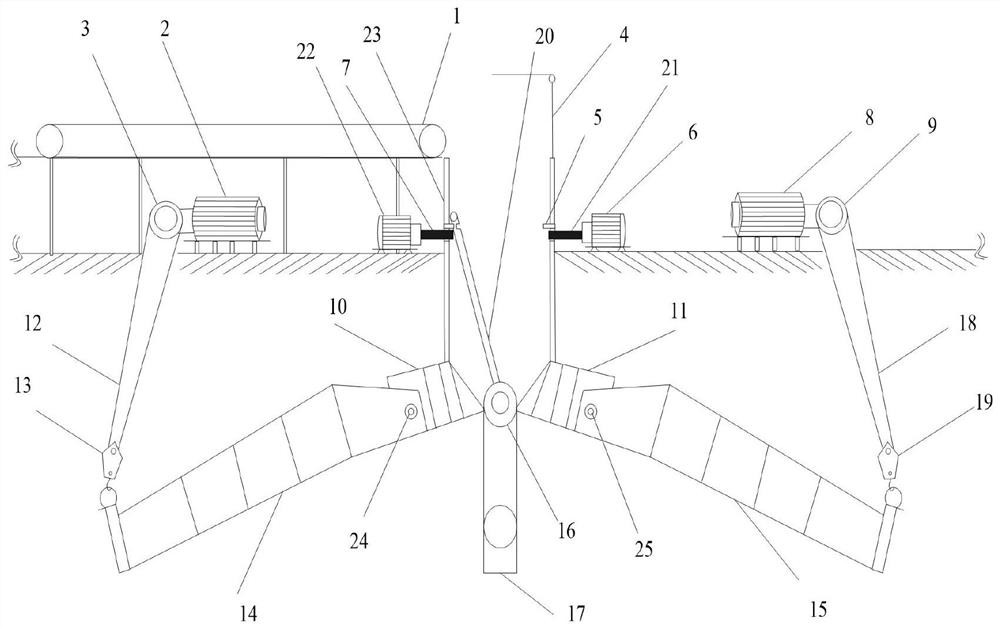

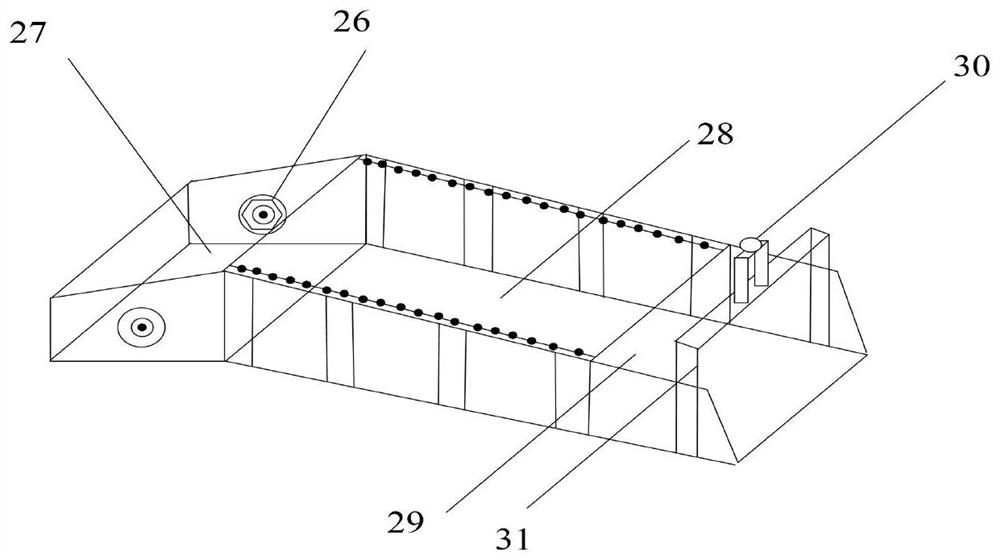

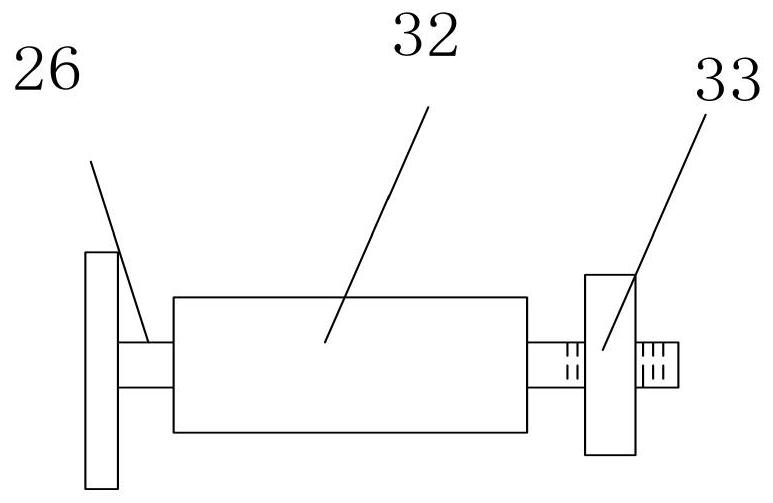

[0020] Such as figure 1 As shown, a schematic diagram of the overall structure of a traction type front and rear two-way chute device for bulk materials, including 1. Belt conveyor; 2. Front traction motor; 3. Front traction drum; 4. Material baffle; 5. Wedge iron 6. Rear hydraulic cylinder; 7. Front hydraulic push rod; 8. Rear traction motor; 9. Rear traction drum; 10. Front fixed inner chute; 11. Rear fixed inner chute; 12. Front traction wire rope; 13. Front traction roller hook; 14. Front movable outer chute; 15. Rear movable outer chute; 16. Turning plate rotation shaft; 17. Anti-chute collision baffle; 18. Rear traction wire rope; 19. Rear traction roller hook; 20 21, the rear hydraulic push rod; 22, the front hydraulic cylinder; 23, the main buffer storehouse; 24, the front chute shaft; 25, the rear chute shaft.

[0021] First, the bulk material is transported to the main body buffer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com