Manufacturing method of automatic disc loosening and winding machine and programming calculation and control mode

A production method and control mode technology, applied in program control, electrical program control, general control system, etc., can solve problems such as product deformation and damage, and achieve the effect of reducing inertial noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

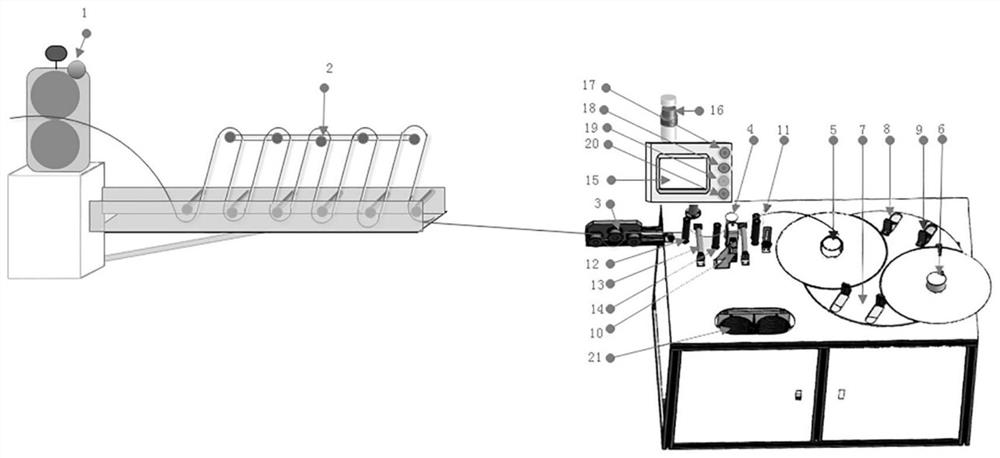

[0030] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the following embodiments do not limit the present invention, and different embodiments can be combined and replaced.

[0031] Such as figure 1 As shown, wherein the product passes through the tension system 23 and the first guide wheel 11, the second guide wheel 12, the third guide wheel 13 and the fourth guide wheel 14 after coming out of the discharge port 1, and enters the feeding roller group 4 to be transported to The receiving tray 5 is rewound.

[0032] Heat-shrinkable tubing or other products can be changed in diameter and width, and the number of meters to be rolled can be controlled and set according to demand.

[0033] The conveying line speed of the feeding roller group 4 is slightly faster than the line speed of the discharge port 1, and the meter number L1 of the discharge meter counter 1 at the discharge port can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com